The working principle and characteristics of roller press

1.1 Working principle The working efficiency of a crushing device depends on its working principle. And their working principle is closely related to the mechanism of material crushing. Therefore, it is necessary to systematically study the crushing mechanism of materials and comprehensively describe the working conditions of crushing equipment so as to realize the crushing mechanism of materials by using some equipment and achieve the purpose of high efficiency and energy saving. This requires research in the following aspects:

1. The physical process of crushing;

2. Single particle crushing research;

3. Material layer crushing research;

4. Mathematical simulation of crushing process;

5. Working condition and optimal control of crushing equipment. The material particles are deformed and then broken by the mechanical force exerted by the crushing machine. The change of material particle size from big to small is a physical process. The internal relationship of this process can be revealed by single particle crushing and layer crushing.

(1) Single particle crushing German scholars have conducted a lot of research on single particle crushing since the 1960s. The main equipment used is pressure testing machine, compression-shear combined testing machine and roll machine. The test shows that the strain of the material particles under pure pressure is much larger than that under shear force. This is the theoretical basis of the production of roller press. The grinding method of the tube mill basically belongs to the category of single particle grinding. The material particles in the tube mill are impacted and ground between the grinding medium and between the grinding material and the lining plate, and the process of the crushing material particles from large to small is very random. That is to say, the energy distribution spectrum generated by the grinding ball movement is very wide. Too large or too small energy can not be reasonably absorbed by the material in the crushing process in time, so the effective utilization rate of energy is very low. Because there are large pores between the grinding medium, it is theoretically point or line contact, so the material belongs to the category of single particle crushing. In the process of crushing materials, a layer of fine powder is often adsorbed on the surface of the grinding medium and the lining plate to act as a cushion layer. On the one hand, this layer of fine powder absorbs energy for re-grinding, and the material particles are too fine, which causes the so-called "over-grinding" and consumes unnecessary energy; On the other hand, the material particles that really need to be ground can not get sufficient impact energy. There is always a retention zone in the movement path of the grinding body, and the grinding body basically makes no effort and wastes energy in this area. A grinding body in the tube mill, the cycle impact 1000 times, only one impact on the material particles to crush work, the rest of the impact is ineffective, but the work done to improve them is wasted. This is the basic reason for the extremely low grinding efficiency and high power consumption of the tube mill. Although people have continuously improved the tube mill and its grinding system, especially the internal structure of the mill itself and the many beneficial measures taken to improve the efficiency of the powder selection equipment in the system, and have achieved certain results, but the final grinding mechanism has not changed greatly, so the power consumption of the cement clinker crushing and grinding system is still difficult to reduce to 32kWh /t. If you want to improve the cement label, its unit grinding power consumption will also surge.

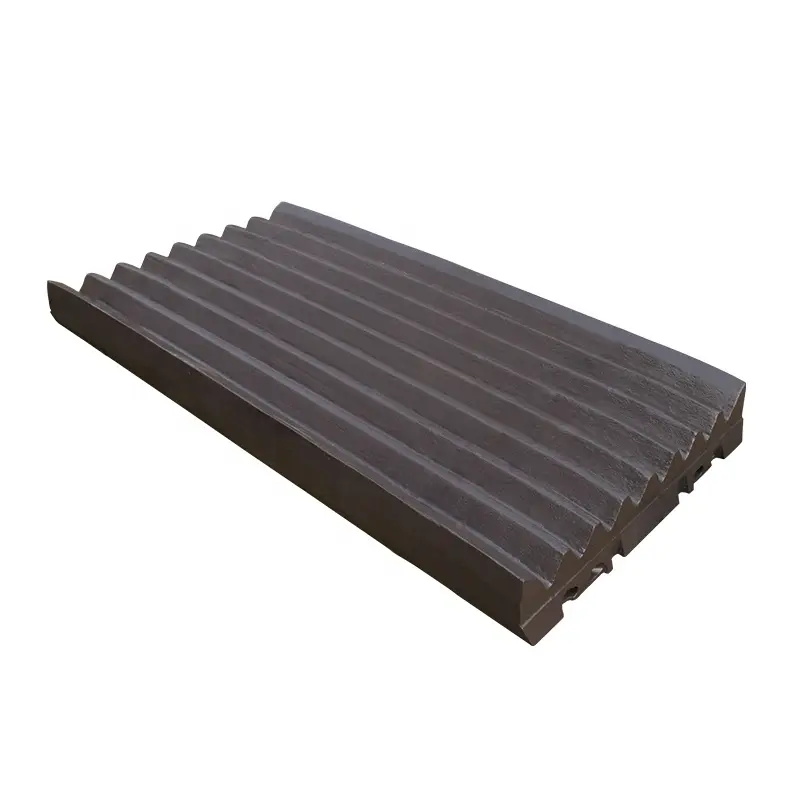

(2) Material layer crushing vertical mill is a low pressure material layer crushing industrial equipment. In addition to the main pressure action, the material layer is also subjected to a certain shear action between the roller and the disk. This is because in the rolling process of the roller and the mill, in addition to the relative speed on the center line circumference is zero, there is a certain relative speed on both sides and the greater the distance from the center of the mill. In addition, when the material layer is subjected to pressure, this pressure is transferred between the material particles in the material layer, and the material particles under the rolling action are subjected to a certain shear effect. The strain of the material particles under shearing force is much smaller than that under pressure, and the strength and proportion of the pressure action are much larger than that of the tube mill. In addition, the vertical mill is the material layer pulverization, forming a certain material bed, in the edge of the cross section, its centrifugal force, will not fall to the inside of the pile extension, the outside is set up an adjustable height of the coaling plate block, can only throw a part, unlike the material in the tube mill, when the impact of the mill ball, can be moved around arbitrarily, so that the affected particles are not about no bundles. Very little impact work is absorbed. Therefore, the grinding efficiency of the vertical mill is higher than that of the tube mill, and the power consumption is relatively low. The vertical mill relies on centrifugal force and liquid pressure to exert pressure on the material layer through the grinding roller, and the grinding disc rotates to drive the grinding roller to roll around its own center line. It is obvious that the pressure of the vertical mill is much higher than that of the tube mill. But relative to the roller press, this pressure is much lower. Therefore, the vertical mill is a low-pressure material layer crushing equipment. Due to the small pressure, the material layer is relatively loose, and there is mutual extrusion between the material particles, so that the surface is subjected to stripping and grinding, that is, subjected to shearing force. The working principle of the roller press is shown in Figure 2-1, which mainly relies on two horizontally mounted and synchronously rotating extrusion rollers to crush the high pressure material layer. When the closed material layer is forced to move downward, the extrusion pressure gradually increases enough until it is crushed and extruded into a dense material cake and discharged from the machine. The mechanical strength of this cake is very low, and it can be broken by hand twisting. The cake contains a large number of fine powder, of which the finished fine particles less than 90μm account for about 20 to 30%, the internal structure of the coarse particles has been destroyed, resulting in many micro-cracks, and high grillability. That is to say, the material particles less than 2 mm in the extruded cake account for about 60 to 70%, and there are many micro-cracks.

The working principle of the roller press is similar to the roller crusher from the appearance, there are two opposite rotating rolls, under the action of external thrust, the material is "broken", but their working principle is completely different. The working principle of the roller press is simply summarized: high pressure material layer crushing. Compared to the crusher this is:

1. The extrusion pressure provided by the hydraulic system reaches hundreds of tons or even thousands of tons, that is, the pressure is high.

2. It is not a single particle crushing, but a high-pressure material layer crushing between materials in a closed space. Roller press energy saving lies in this.

1.2 Main characteristics of roller mill grinding According to the practical application results of roller mill in the cement industry, the following main characteristics are summarized:

(1) Increase production: The installation of a roller press in the grinding system can give full play to the potential capacity of the grinding equipment, increase production by 50-100%, and improve the production efficiency of the entire system.

(2) Reduce power consumption: Grinding materials with a press can significantly reduce the total power consumption of the grinding system. Compared with the traditional grinding method, energy saving 25-50%, the annual power saving benefit is considerable.

(3) Saving investment: Compared with the tube mill, the roller mill with the same production capacity has a simple structure, small size, light weight, and small factory space, which can save civil construction investment, and also facilitate the transformation of the original grinding system. In addition, the operation and maintenance of the roller press is also very simple.

(4) Good working environment: the material is continuously and stably squeezed and crushed in the extrusion roll cover, and the harmful dust is not easy to spread, at the same time, because there is almost no impact, the noise of the roller is much smaller than that of the tube mill.

(5) Easy to develop: the traditional tube mill is limited by processing, transportation, heat treatment and other conditions, and the large-scale tube mill is greatly restricted. The grinding system of roller press can solve this problem well. The large-scale development of the grinding system has become a reality.

1.3 Stable working conditions of the roller press After years of practice, the safe and stable working of the roller press must meet the following conditions:

(1) The feeding material should have a certain material pressure, so as to ensure that the material is steadily and continuously fed into the roller to form a more dense material layer.

(2) The granularity of the fed material should meet the design requirements to form a more dense material layer, except for the part where single particles can be broken before the high pressure material layer is crushed.

(3) Grinding should have a large enough extrusion crushing force, however, the crushing force value for different materials and extrusion effects have different requirements, should be determined by testing the best value.