The fastening method of plate hammer is introduced

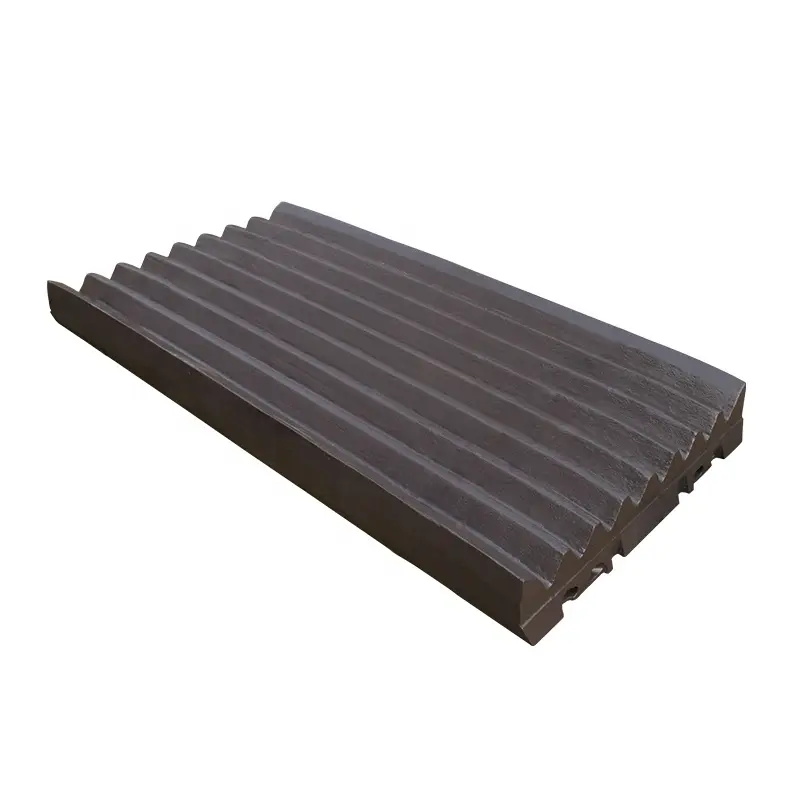

The impact crusher should be widely used in the crushing of river pebbles, granite, basalt, iron ore, limestone, quartz stone and other materials, and the impact crusher wear-resistant parts plate hammer is the core wear-resistant parts, because the plate hammer is mainly broken materials in the impact crusher, Therefore, the design of counterattack hammer should meet the requirements of reliable work, easy loading and unloading and improving the metal utilization rate of hammer. Impact crusher plate hammer is generally made of high chromium cast iron, high manganese steel and other wear-resistant alloy steel. There are many shapes, which are generally closely related to the fastening method and the working load, and the commonly used is a strip shape. In the process of work, the impact crusher plate hammer is mainly responsible for high-speed impact on the material, direct contact with the material, driven by the rotor to do high-speed rotation, easy to appear loose phenomenon, so it needs to be fastened, this article on its fastening method is introduced in detail.

1 Impact crusher wear-resisting parts plate hammer embedment fastening method

The plate hammer is inserted into the groove of the rotor from the side, and the two ends need to be positioned with a pressure plate, which can prevent axial movement, because the fastening bolts are removed, and the reliability of the plate hammer is improved. The centrifugal force generated when the hammer head is turned and the reaction force when the impact is broken are fastened and self-locking, and the parts of the rotor that are vulnerable to wear are made into a replaceable structure, so the loading and unloading is simple and the production is simple. The metal utilization rate of the method is low, but the improved embedded-fastening method adopts a slotted plate hammer with a longitudinal groove on the hammer surface, which greatly reduces the metal consumption rate, and the working face can be changed for four times, effectively prolonging the service life of the plate hammer.

2 Impact crusher wear-resisting parts plate hammer wedge fastening method

The method is mainly to insert the wedge into the corresponding slot between the plate hammer and the rotor to tighten it. Wedge fastening method is more reliable, loading and unloading is more convenient, because the relative shift between the plate hammer and the rotor is eliminated, the rotor wear is reduced. It can greatly reduce the wear degree of the plate hammer and the rotor, but the utilization rate of the metal may be low.

3 Impact crusher wear-resisting parts plate hammer bolt fastening method

The method is that the plate hammer is fastened to the plate hammer seat of the rotor by means of bolts. The hammer seat has a tenon shape, and the tenon can be used to bear the impact force of the hammer when working, avoid the shear of the bolt and improve the reliability of the bolt connection. The tightening of the bolt must be carried out in two stages, the first time is the initial screw. The initial tightening is fixed to 60% ~ 80% of the standard axial force of the bolt, and the torque value of the initial screwing shall not be less than 30% of the final screwing torque value. The second fastening is the final screw, and when the final screw is twisted, the high-strength shear bolt should screw off the card head. In order to make all bolts in the bolt group evenly stressed, the initial screw and the final screw should be carried out in a certain order.

In addition to the above several fastening methods, high-quality materials can be used to make a plate hammer, reduce wear and loosen, and regularly check the fastening situation to avoid the phenomenon of loose equipment operation failure.