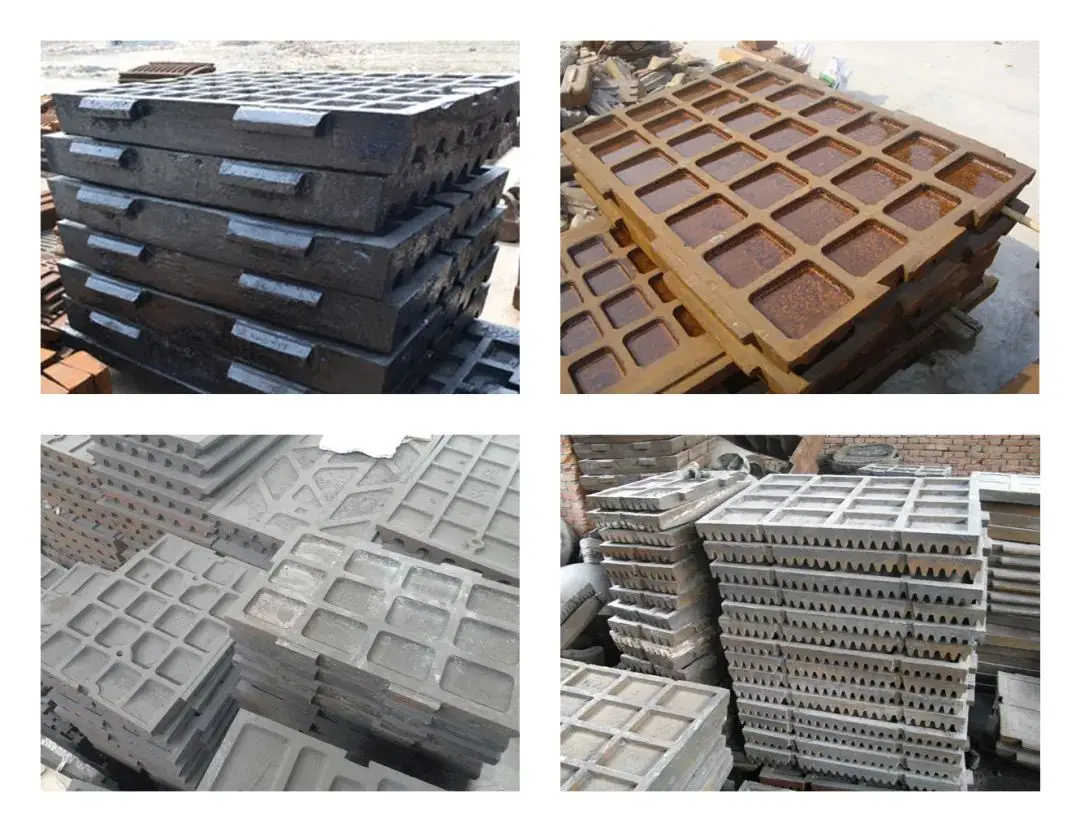

The detailed process flow of casting

The main processes of sand casting are:

1. Mold production: Make molds according to the requirements of drawings. Generally, wood molds can be used for single production, plastic molds and metal molds can be made for mass production, and templates can be made for mass castings.

2. Sand mixing stage: according to the requirements of sand manufacturing and the types of castings, qualified sand is prepared for modeling.

3. Modeling (core making) stage: includes modeling (forming the cavity of the casting with molding sand), core making (forming the internal shape of the casting), and mold setting (putting the nixing core into the cavity and closing the upper and lower sand boxes). Molding is the key link in casting.

4. Melting stage: according to the required metal composition with good chemical composition, select the appropriate melting furnace to melt alloy materials, forming qualified liquid metal liquid (including qualified composition, temperature qualified)

5. Pouring stage: The qualified molten metal is injected into the sand box with a good mold. The risk of pouring stage is relatively large, special attention should be paid.

6. Cleaning stage: after pouring and other molten metal solidification, remove the molding sand, knock off the gate and other accessories, and form the required casting.