The application fields of HPGR Rollers

In modern industry, efficient crushing and grinding technologies are crucial for resource recovery and material processing. The high-pressure roller mill (HPGR) Rollers, as an advanced crushing technology, have been widely applied in multiple industries due to their high efficiency, energy conservation and environmental protection features. This article will explore the wide application of HPGR Rollers in fields such as mining, cement industry and construction waste treatment, as well as how they meet the specific needs of various industries.

First, Introduction to HPGR Rollers

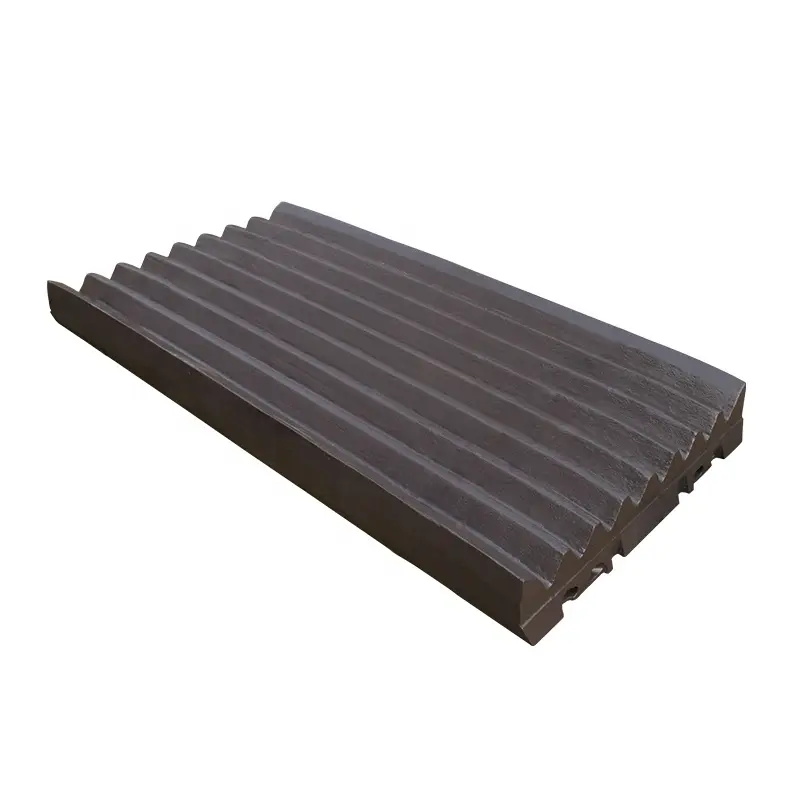

The high-pressure roller mill (HPGR) Rollers is a device that uses high-pressure rollers to crush and grind materials. Its working principle is to apply high pressure to the material through two relatively rotating high-pressure rollers, causing the material to be subjected to squeezing and shearing forces between the rollers, thereby achieving crushing and grinding. HPGR Rollers have the advantages of large crushing ratio, low energy consumption and uniform product particle size. They are particularly suitable for processing materials with high hardness.

Second, the application of HPGR Rollers in the mining industry

In the field of mining, HPGR Rollers are widely used in the crushing and pre-grinding of ores. The hardness and particle size of ores are usually high, and traditional crushing equipment consumes a lot of energy and has low efficiency during processing. The HPGR Rollers can effectively crush the ore through the squeezing effect of the high-pressure rollers and reduce the energy consumption of subsequent grinding. Furthermore, the HPGR Rollers can also adjust the roller pressure and roller speed according to the properties of the ore to achieve the best crushing effect.

1.Crushing of hard rock ores

For hard rock ores with high hardness, such as granite, quartzite, etc., HPGR Rollers can provide efficient crushing solutions. By adjusting the roller pressure and roller speed, HPGR Rollers can crush the ore to the required particle size, while reducing the overcrushing phenomenon and improving the recovery rate of the ore.

2. Pre-grinding treatment

In the grinding process, HPGR Rollers can be used as pre-grinding equipment to crush the ore to a finer particle size, thereby reducing the load of the ball mill or rod mill and improving the grinding efficiency. Pre-grinding treatment can not only save energy consumption, but also improve the grindability of the ore and enhance the effect of the subsequent beneficiation process.

Third, the application of HPGR Rollers in the cement industry

In the cement production process, the crushing and grinding of raw materials are key links. The application of HPGR Rollers in the cement industry is mainly concentrated in the crushing of clinker and raw materials, as well as in the cement grinding process.

1. Clinker crushing

Cement clinker has a relatively high hardness, and traditional crushing equipment is prone to wear and high energy consumption during processing. The HPGR Rollers can effectively crush clinker through the squeezing effect of high-pressure rollers, reducing energy consumption and equipment wear. Meanwhile, the HPGR Rollers can also adjust the roller pressure and roller speed according to the properties of the clinker to achieve the best crushing effect.

2. Pre-grinding of raw materials

During the cement grinding process, the HPGR Rollers can be used as pre-grinding equipment to crush the raw materials to a finer particle size, thereby improving the grinding efficiency. Pre-grinding treatment not only saves energy consumption but also improves the performance of cement, enhancing its strength and durability.

Fourth, the application of HPGR Rollers in the treatment of construction waste

With the acceleration of urbanization, the treatment of construction waste has become an important environmental issue. The application of HPGR Rollers in the treatment of construction waste mainly focuses on the crushing and recycling of construction waste.

1. Construction waste crushing

Construction waste usually contains a large amount of hard materials such as concrete blocks, bricks and stones. HPGR Rollers can effectively crush these materials and reduce them to a smaller particle size, facilitating subsequent recycling and utilization. By adjusting the roller pressure and roller speed, HPGR Rollers can achieve efficient crushing effects while reducing energy consumption and equipment wear.

2. Recycling

The crushed construction waste can be used to produce recycled aggregates, roadbed materials or fill materials, etc. HPGR Rollers can provide a uniform particle size distribution, improve the recycling rate of construction waste, reduce the exploitation of natural resources, and at the same time lower the environmental impact of construction waste.

Fifth, meet the specific needs of various industries

The reason why HPGR Rollers can be widely used in fields such as mining, cement industry and construction waste treatment is that they can meet the specific needs of various industries:

1. Efficient crushing

The HPGR Rollers can effectively crush materials with high hardness through the squeezing effect of high-pressure rollers, reducing energy consumption and equipment wear. This highly efficient crushing method is particularly suitable for processing materials with high hardness such as ores, clinker and construction waste.

2. Uniform particle size

HPGR Rollers can provide a uniform particle size distribution and meet the requirements of material particle size in various industries. In the mining industry, a uniform particle size distribution can increase the recovery rate of ores. In the cement industry, a uniform particle size distribution can improve the performance of cement. In the treatment of construction waste, a uniform particle size distribution can enhance the recycling rate of construction waste.

3. Energy conservation and environmental protection

HPGR Rollers have low energy consumption during the crushing and grinding process, which can significantly reduce the operating costs of enterprises. Meanwhile, the efficient crushing method of HPGR Rollers can reduce the exploitation of natural resources, lower the environmental impact of construction waste, and meet the requirements of sustainable development.

HPGR Rollers, as an advanced crushing technology, have been widely applied in fields such as mining, the cement industry and construction waste treatment. They meet the specific demands of various industries through efficient crushing methods, uniform particle size distribution and energy conservation and environmental protection features. Whether in ore crushing, cement production or construction waste treatment, HPGR Rollers can provide efficient solutions to help enterprises improve production efficiency, reduce operating costs and achieve sustainable development.

With the continuous advancement of technology, the application scope of HPGR Rollers will be further expanded, providing more efficient, energy-saving and environmentally friendly crushing and grinding solutions for various industries.