Roller surface wear repair method

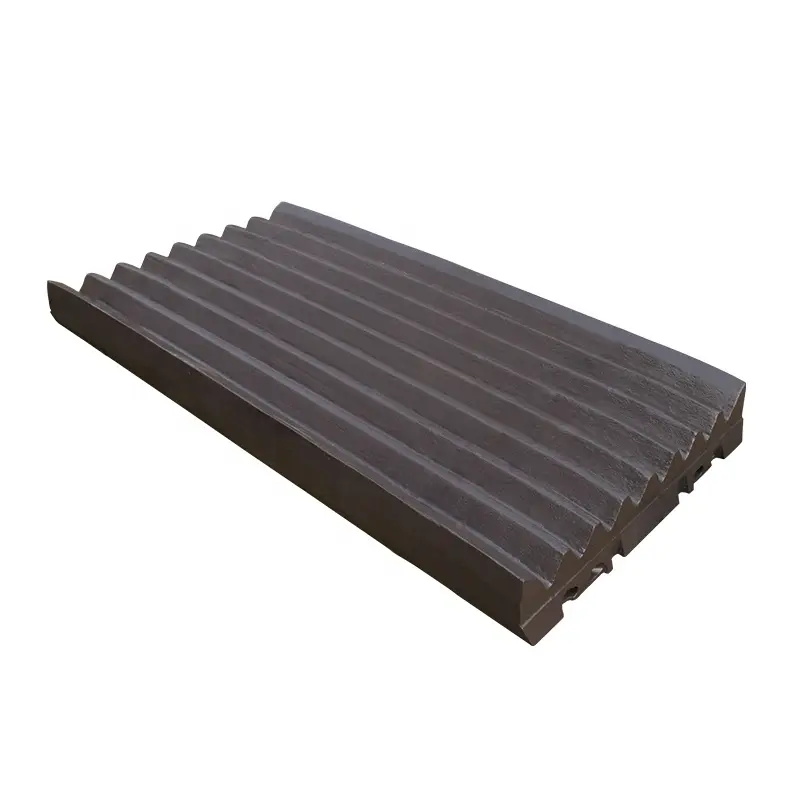

The 1 roll press plays a huge role in cement production. With the increase of the use time, the wear of the roll surface also accelerates accordingly, especially after the wear layer is worn off, it is easy to peel off the block when the hard material part is stressed, which brings great troubles to the use of the roll press. We have summarized the experience in the surfacing welding work of the roll surface of the maintenance roll press and shared with my colleagues.

2 Repair Methods

2.1 Manual arc welding surfacing

In the production practice, when the wear surfacing of the roll surface is sometimes less wear and shallow pits, in order to complete the surfacing quickly, manual arc welding can be used. Clean the pits when surfacing, and it is best to blow the concave surface clean with dry compressed air to facilitate the full fusion of the surfacing layer. In the operation, the current should be appropriate, the current is too small and the fusion is not good, the current is too large and it is easy to produce hot cracks, and the welding layer should not be too thick during welding, and the second layer should be surfacing after the temperature of the first layer is lowered, so that the repeated surfacing effect is better.

2.2 Two protection welding surfacing

This is generally done when the planned downtime is adequate. At this time, the wear surface of the roll surface is large and the roll surface is uneven, which can be divided into two situations: first, the wear-resistant layer has not been worn off, then you can use 1.6mm core-pattern layer welding wire for surfacing repair, and you can also repair the wear-resistant layer according to the surface pattern or polka dots; Second, if the wear-resistant layer has been worn off to expose the bottom layer, then the bottom layer of 1.0mm welding wire is filled with CO₂ gas protection welding, and when the pit is filled with a thickness of 10mm from the working face, the cover is filled with 1.6mm cored layer welding wire, so that the roll surface of the surfacing welding is strong and durable.

If it is also necessary to increase the wear resistance of the surfacing pattern and the dot on the roll surface, it is necessary to follow the spacing between the pattern and the pattern of about 8mm, the spacing between the point and the point of about 6mm, and the distance can not be too close, otherwise it is likely to fall off in use, because the roller should maintain the temperature in the whole surfacing process. This surfacing repair caused by the rise in temperature, so there are differences in the fusion of the material, so in the maintenance of a certain distance in the surfacing welding, in order to ensure that the heat is not too concentrated, local stress concentration, and leave hidden dangers for spalling.

3 Closing remarks

In the long-term repair of roller surfacing, these methods can effectively increase the service time of the roller press and extend the replacement and maintenance cycle, which is conducive to the normal production.