Note: High yield and high efficiency start from the correct operation!

Correct operation and maintenance is crucial to the efficiency and service life of crushing equipment, and I believe that every user is also deeply touched. So what should we pay attention to in daily operation? This article tells you the key points of operation before starting, during operation and when stopping.

Preparation before starting:

1) Equipment lubrication, electrical (instrument) control system and other inspection is completed to ensure that it meets the operation requirements;

2) Check that all fastening bolts are in good condition;

3) Check whether the belt is damaged and whether it is wiped clean; Check the tightness of the belt, when the belt is static, press the thickness of 1~2 belts is appropriate;

4) Check whether the protective device and the enclosure are intact;

5) Check that there is no foreign body in the crushing chamber, and the hand-driven triangle belt wheel rotates more than one circle without collision;

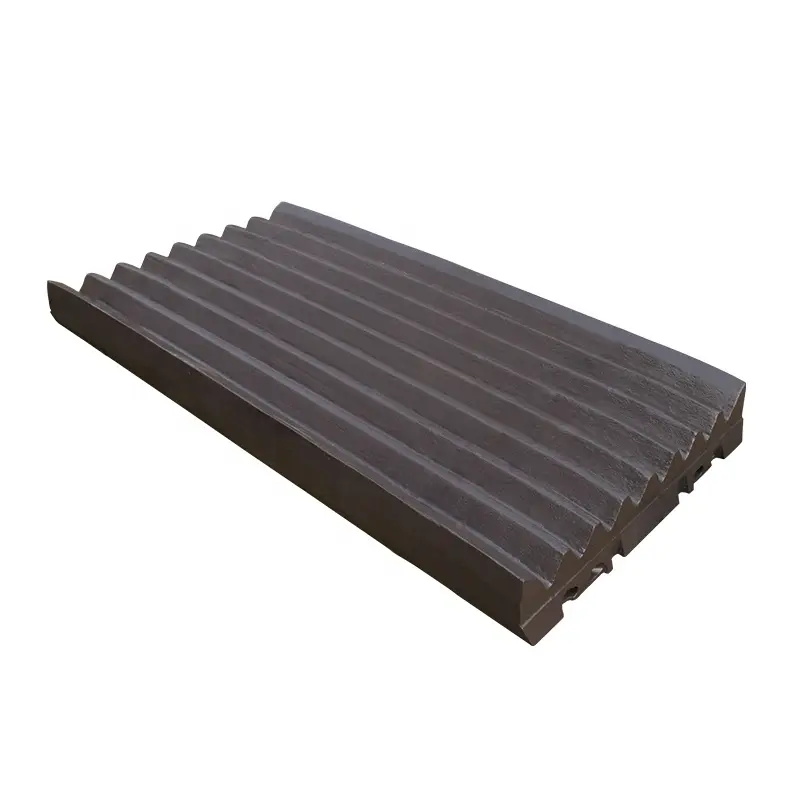

6) Ensure that the gap between the hammer head and the liner in the circumference is within the range of 9mm~12mm;

7) Check that the wear condition of the hammer head is kept within 30% of the total volume.

Note when starting:

1) Boot sequence: discharge equipment -- hammer crusher -- feeding equipment;

2) The hammer crusher can be started only when there is no material in the body;

3) After the belt conveyor is running normally, start the hammer crusher without load, and no abnormal condition can be found after idling for 2min.

4) Equipped with continuous feeding equipment, and the feeding is uniform, the front side of the feeding port must be installed with high-strength magnets, and the installation of iron removal and belt conveyor must meet the requirements, to ensure that no foreign matter such as metal into the hammer breaking machine, so as to avoid damage to the equipment or cause accidents;

5) Check whether there is abnormal sound and vibration when the equipment is in normal operation;

6) Normal lubrication, lubrication parts do not leak oil, transmission V-belt does not slip;

7) The temperature rise of the bearing shall not exceed 40℃, and the maximum temperature shall not exceed 80℃;

8) Continuous load running time should not be less than 3h;

9) When the equipment is running, do not open the shell, do not disassemble parts and pulley and other dangerous parts;

10) The hammer and liner should be checked once per shift, the replacement of the hammer should be weighed, the heavy in the middle, the light on both sides, the total weight of each row does not exceed 0.5kg;

11) The wear of the hammer handle at ϕ50 with the hammer rod is not allowed to exceed 5mm. If the wear exceeds 5mm, the hammer handle should be replaced or the wear area should be repaired before use;

12) Correct use of safety signals, such as accidents, or other emergency, immediately press the emergency stop button, make records and report in time;

13) It is strictly forbidden to peep into the inlet during operation;

14) When the crusher is running, the staff can not stand in the rotor inertia force line, and it is strictly prohibited to carry out any cleaning, adjustment, maintenance work.

Precautions during shutdown:

1) Stop sequence: feeding equipment -- hammer crusher -- discharging equipment;

2) The feed should be stopped before stopping, and the motor should be turned off after the material in the crushing chamber is safely discharged; At the same time, re-reinforce the bolt of the lining plate to prevent loosening and damage to the device.

3) Clean the dust on the hammer crusher, clean and lubricate the equipment, the bearing needs to be oiled once every half month in winter and once a week in summer;

4) Remove the scrap iron on the iron remover once per shift.