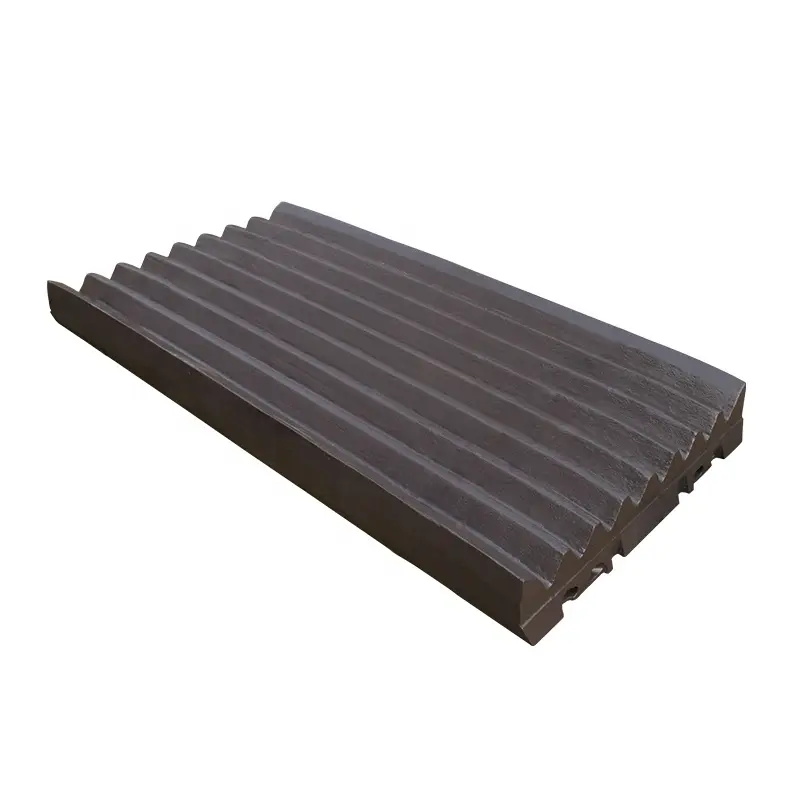

Jaw plate: the key component of the jaw crusher

Jaw crusher as a kind of crushing equipment widely used in mining, building materials, chemical industry and other fields, one of its core components is the jaw plate. The jaw plate plays a crucial role in the crushing process, which not only directly affects the crushing efficiency and effect, but also determines the stability and service life of the equipment. This article will deeply analyze the role of the jaw plate and its importance in the crushing process to help international wholesale buyers better understand this key part.

First, the role of the mouth plate

1. Material guiding and crushing

The main function of the jaw plate is to guide the material into the crushing chamber and break between the moving jaw plate and the fixed jaw plate. The shape and size of the jaws are designed to facilitate uniform material distribution and efficient crushing. In the crushing process, the material is squeezed, bent, and split, eventually reaching the desired particle size.

2. Protect the jaw plate

The jaw plate also protects the jaw plate. Because the jaw plate is in direct contact with the material, it is subjected to huge crushing force and friction, and it is easy to wear. Through its wear-resistant design, the jaw plate reduces the direct wear of the jaw plate and prolonging the service life of the jaw plate.

3. Control the crushing size

The shape and size of the jaw plate also affect the uniformity of the crushing particle size. By adjusting the gap of the jaw plate, the particle size of the broken material can be controlled. This is essential to ensure the quality of the broken product.

Second, the importance of the jaw plate in the crushing process

1. Crushing efficiency

The design of the jaw plate directly affects the crushing efficiency. The efficient jaw plate design can ensure that the material is broken quickly and evenly in the crushing chamber, reducing the residence time of the material in the crushing chamber. This not only improves the crushing efficiency, but also reduces the energy consumption of the equipment.

2. Device stability

The wear resistance and stability of the jaw plate are crucial to the overall stability of the equipment. High quality jaw plates can maintain good performance during long periods of operation, reducing the vibration and failure rate of equipment. This is very important to ensure the stable operation of the equipment and reduce maintenance costs.

3. Service life

The service life of the jaw plate directly affects the maintenance cost of the equipment. The wear-resistant jaw plate can maintain a long service life under harsh working conditions and reduce the frequency of replacement. This not only reduces the operating cost of the equipment, but also reduces the production loss caused by equipment downtime and maintenance.

Third, the material and design of the mouth plate

1. Wear-resistant material

The jaw plate is usually made of high manganese steel, alloy steel and other wear-resistant materials. These materials have high strength and good wear resistance, and can withstand the huge impact force and friction during the crushing process.

2. Optimize the design

Modern jaw plate design adopts computer optimization technology to achieve the best crushing effect. The optimized jaw plate not only improves the crushing efficiency, but also reduces the excessive crushing and waste of materials.

Fourth, the maintenance and replacement of the mouth plate

1. Check regularly

Regular inspection of the wear of the jaw plate is an important measure to ensure the normal operation of the equipment. Through regular inspection, the mouth plate with serious wear can be found in time and replaced.

2. Replacement interval

The replacement cycle of the jaw plate depends on its wear and the frequency of use of the equipment. In general, when the wear of the jaw plate exceeds 30% of its thickness, it needs to be replaced.

As a key component of jaw crusher, jaw jaw plate plays a vital role in the crushing process. It not only directly affects the crushing efficiency and effect, but also determines the stability and service life of the equipment. By selecting high-quality wear-resistant materials and optimizing design, the performance and service life of the jaw plate can be significantly improved. At the same time, regular inspection and timely replacement of worn jaws are also important measures to ensure the normal operation of the equipment.

If you have any further questions or need more detailed information, please feel free to contact us.