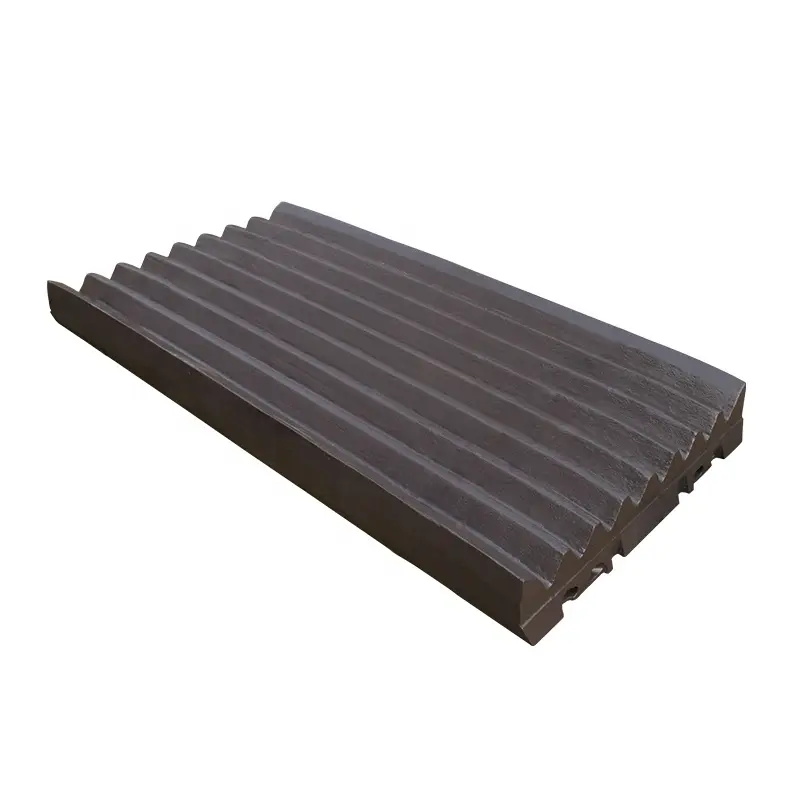

Impact crusher buffer plate

In modern mining and industrial production, the impact crusher is widely used because of its high efficiency and flexible characteristics. However, the strong impact force generated during the crushing process causes serious wear to the inner wall of the equipment and wearing parts, which has been a problem faced by the industry. In recent years, with the continuous progress of technology, the application of buffer plate technology in the impact crusher has gradually matured, providing an effective guarantee for the stable operation and service life of the equipment.

First, the structure and principle of buffer plate

The core design of the buffer plate lies in its unique structure and material choice. Taking the inner wall structure of a high buffer protection impact crusher as an example, the design can effectively absorb the impact force generated when the stone is broken by installing a buffer plate with a spring and a rubber block in the inner wall of the crusher. Specifically, the buffer plate is composed of a mounting plate, a movable plate, a spring and a rubber block, and the telescopic action of the spring with the buffer effect of the rubber block can significantly reduce the direct impact of the stone on the inner wall, thereby extending the service life of the equipment.

Second, the application advantages of buffer board

Prolong the life of the equipment: the buffer plate reduces the wear of the inner wall of the crusher and the wearing parts by absorbing the impact force, and reduces the maintenance cost and replacement frequency of the equipment.

Improve production efficiency: The stable buffer effect makes the crusher more stable during operation, reducing the downtime caused by impact, thereby improving the overall production efficiency.

Noise reduction: The rubber material and spring structure of the buffer plate can effectively absorb noise, providing a quieter working environment for the operator.

Intelligent protection: Some new buffer board designs are also combined with the hydraulic system, which can realize overload protection and automatic adjustment of the discharge port, further improving the intelligent level of the equipment.

Third, market trends and technical prospects

With the continuous improvement of environmental protection and efficient production requirements, the buffer plate technology of impact crusher is also constantly upgraded. In the future, the buffer board will develop in the direction of more efficient, more intelligent and more environmentally friendly. For example, the buffer plate using new polymer materials and composite materials not only has better buffer performance, but also can achieve higher wear resistance and corrosion resistance. In addition, the intelligent buffer system combined with the Internet of Things technology can monitor the operating status of the equipment in real time, warn potential failures in advance, and provide a more scientific basis for the maintenance and management of the equipment.

The application of buffer plate technology in impact crusher not only solves the wear problem of traditional equipment, but also brings higher efficiency and lower cost for industrial production. With the continuous progress of technology, the buffer plate will play an important role in more areas, providing more reliable protection for mine and industrial production.