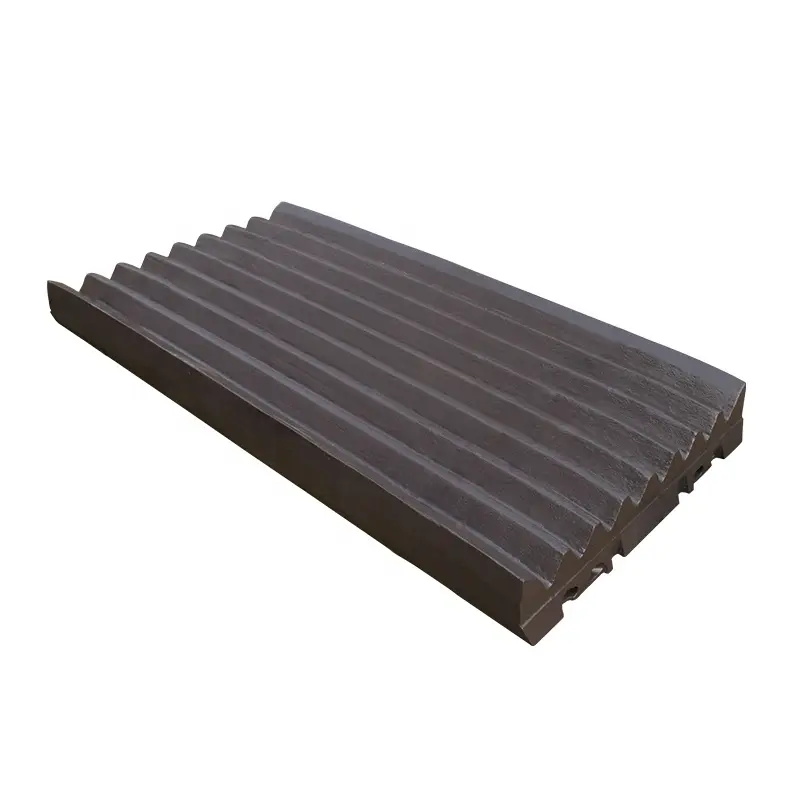

Identification and treatment of cheek plate wear

In the field of industrial production and mechanical manufacturing, the cheek plate is a key part of many equipment, and its wear directly affects the performance and service life of the equipment. For international wholesale buyers, understanding the identification and treatment methods of cheek wear can not only improve the maintenance efficiency of the equipment, but also ensure the reliable quality of the purchased products, thereby enhancing customer satisfaction and market competitiveness. This article will describe in detail the identification methods, treatment measures and prevention strategies of cheek plate wear to help you better manage and maintain related equipment.

First. Identification method of cheek plate wear

1. Check appearance

Initial identification of cheek plate wear can be done by visual inspection. Inspectors should carefully observe whether there are cracks, scratches, depressions and other abnormal conditions on the surface of the cheek plate. These signs usually indicate that the cheek plate has been subjected to some degree of wear. For example, in the inspection of the cheek plate of a tire mold, microscopic cracks and wear marks on the surface can be found through the appearance inspection.

2. Size measurement

Use an accurate measuring tool, such as a caliper or micrometer, to measure the key dimensions of the cheek plate. Compared with the original design size, the size change can be found to determine the degree of wear. When the size changes beyond the allowable range, it indicates that the cheek plate is seriously worn and needs further treatment.

3. Ultrasonic detection

Ultrasonic inspection is a non-destructive inspection method that detects internal defects and wear through the propagation characteristics of ultrasonic waves in materials. This method can detect cracks and wear inside the cheek plate and is very effective for early detection of potential problems.

4. Laser scanning

The laser scanning technology can quickly obtain three-dimensional data of the cheek surface, and by comparing with the standard model, the wear area and degree can be accurately identified. This method is suitable for the detection of complex cheek panels and can provide detailed wear analysis reports.

Second, the treatment measures of cheek plate wear

1. Surface repair

For slightly worn cheek panels, their properties can be restored by surface repair techniques. Common surface repair methods include sandblasting, coating repair, etc. Sandblasting can remove rust and dirt from the surface, while coating repair can create a protective layer on the surface to prevent further wear.

2. Mechanical processing

When the cheek plate is more severely worn, it may need to be machined to restore its size and shape. For example, the worn part is removed by machining methods such as turning and milling, and then the surface treatment is carried out to ensure the accuracy and strength of the cheek plate.

3. Replace the parts

If the cheek plate is so worn that its properties cannot be restored by repair or machining, then replacement parts are the only option. The selection of high-quality cheek plate replacement parts can ensure the long-term stable operation of the equipment.

Third, the prevention strategy of cheek plate wear

1. Perform regular maintenance

Establish a regular maintenance schedule, regularly check the wear condition of the cheek plate, and promptly identify and deal with potential problems. Regular maintenance can not only extend the service life of the cheek plate, but also reduce equipment downtime.

2. Optimize operating conditions

By optimizing the operating conditions of the equipment, such as reducing unnecessary high load operation and controlling the operating temperature, the wear of the cheek plate can be effectively reduced. Reasonably adjust the operating parameters of the equipment to ensure that it operates in the best condition.

3. Use high-quality materials

Selecting high quality and wear-resistant cheek material can improve its wear resistance. When purchasing, reputable suppliers should be selected to ensure the quality and performance of materials.

4. Staff training

Conduct professional training for operation and maintenance personnel to understand the identification methods and treatment measures of cheek plate wear. Improving the professional skills of employees can effectively reduce the wear of cheek plates caused by improper operation.

The identification and treatment of cheek wear is the key to ensure the long-term stable operation of equipment. The wear condition of the cheek plate can be accurately identified by the methods of appearance inspection, size measurement, ultrasonic detection and laser scanning. Surface repair, machining and replacement of parts are common treatment measures, while regular maintenance, optimization of operating conditions, use of high-quality materials and staff training are effective strategies to prevent cheek plate wear. For international wholesale buyers, understanding these methods and strategies can not only improve the maintenance efficiency of equipment, but also ensure the reliable quality of purchased products, thereby improving customer satisfaction and market competitiveness.

I hope the above content can help you better understand the identification and treatment methods of cheek plate wear. If you have any further questions or need more detailed information, please feel free to contact us.