How to evaluate the wear resistance of the cheek plate of a jaw crusher?

The cheek plate of the jaw crusher is a key component that comes into direct contact with the material during the crushing process. Its wear resistance directly affects the service life and operational efficiency of the equipment. Evaluating the wear resistance of the cheek plate of a jaw crusher requires a comprehensive consideration of material selection, heat treatment process, structural design, and wear conditions in practical applications. The following are some key factors and methods for evaluating the wear resistance of the buccal plate:

First, material selection

(1) High manganese steel

High manganese steel is the traditional material for the cheek plates of jaw crushers and has excellent resistance to impact loads. However, due to the structural reasons of the crusher, the opening Angle between the moving and fixed jaw plates is too large, which is prone to cause the abrasive to slide, resulting in a low surface hardness of the jaw plates and rapid wear. To enhance the service life of the jaw plate, high manganese steel can be modified by adding elements such as Cr, Mo, W, Ti, V, and Nb to increase its initial hardness and yield strength.

(2) Medium manganese steel

Medium manganese steel enhances wear resistance while maintaining good toughness by reducing the manganese content and adding other alloying elements such as Cr, Si, Mn, Mo, V, etc. Experiments show that the actual service life of medium manganese steel jaw plates is about 20% longer than that of high manganese steel, and the cost is comparable to that of high manganese steel.

(3) High-chromium cast iron

High-chromium cast iron has very high wear resistance, but relatively poor toughness. Some manufacturers use a composite process of high-chromium cast iron and high-manganese steel to produce jaw plates, making them have both high wear resistance and good toughness. The service life of this composite jaw plate has been significantly improved, but the manufacturing process is relatively complex and the cost is relatively high.

(4) Medium carbon low alloy steel

Medium carbon low alloy steel (such as ZG42Mn2Si1REB) has improved wear resistance on the basis of medium carbon steel by adding a small amount of alloying elements (with a total content of less than 5%). Through appropriate heat treatment processes, such as quenching at 900℃ and tempering at 230℃, its hardness and wear resistance can be further enhanced. The experimental results show that the wear resistance of medium carbon low alloy steel is 1.5 times that of high manganese steel, and its cost is lower.

Second, heat treatment process

The heat treatment process has a significant influence on the wear resistance of the cheek plate. Taking ZG42Mn2Si1REB steel as an example, research shows that when the quenching temperature is 900℃, its hardness reaches HRC55 and its wear resistance is the best. At this time, the microstructure is martensite, which has high hardness and low wear loss.

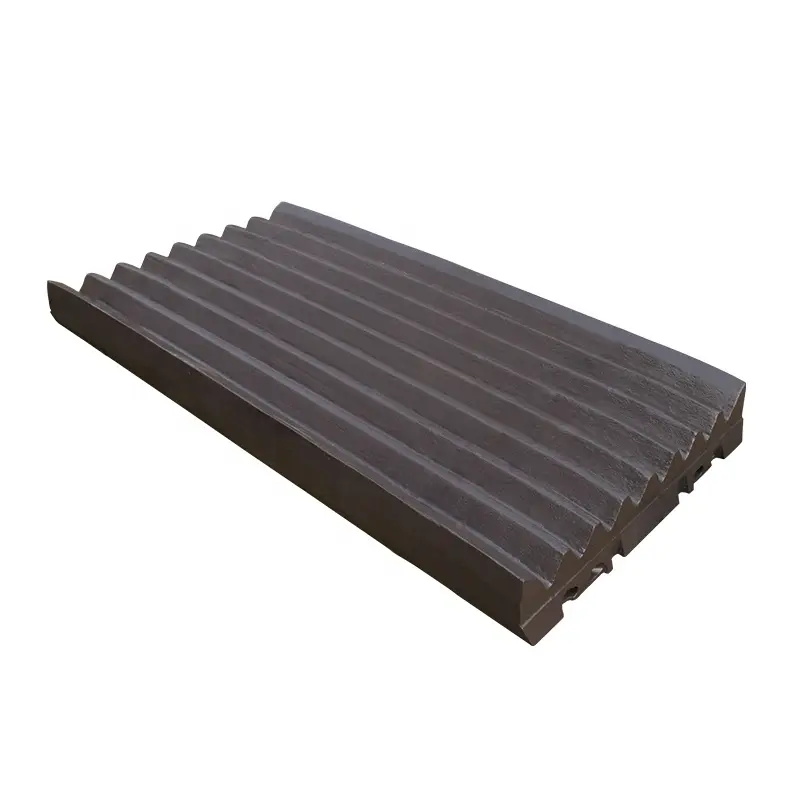

Third, structural design

(1) Tooth profile design

The tooth profile design of the buccal plate has an important influence on its wear resistance. A reasonable tooth profile can reduce the contact area between the material and the cheek plate and lower the wear rate. For instance, pitch and tooth height are key factors influencing wear resistance. Appropriate pitch and height can enhance the crushing efficiency and reduce the wear of the cheek plate at the same time.

(2) Installation and fixation

The installation and fixation methods of the cheek plate also have an impact on its wear resistance. If the cheek plate is not installed firmly, it may become loose during operation, leading to accelerated wear. Therefore, during installation, it is necessary to ensure that the cheek plate makes smooth contact with the machine surface and to use an appropriate fixing method.

Fourth, wear and tear in practical applications

(1) Wear location detection

In practical applications, the wear of the cheek plate should be inspected regularly, and the severely worn parts should be repaired or replaced in a timely manner. For instance, Zhongguan Iron Mine has improved the utilization rate of the jaw plates by adjusting the installation positions of the movable and fixed jaw plates, that is, reversing the up and down positions of the jaw plates themselves and swapping the positions of the movable and fixed jaw plates.

(2) The influence of ore characteristics

The characteristics such as hardness, bulk size and moisture content of the ore have a significant influence on the wear of the cheek plate. When crushing materials with high hardness, the wear of the cheek plate is more severe. Therefore, the appropriate plate material and heat treatment process should be selected based on the characteristics of the ore.

Evaluating the wear resistance of the cheek plate of a jaw crusher requires a comprehensive consideration of material selection, heat treatment process, structural design, and wear conditions in practical applications. By choosing appropriate materials, optimizing heat treatment processes and reasonable structural designs, the wear resistance of the cheek plate can be significantly improved and its service life can be prolonged. In practical applications, regular inspection and maintenance of the cheek plates and adjustment of the crusher parameters based on the characteristics of the ore can further reduce the wear of the cheek plates and improve the operational efficiency of the equipment.

It is hoped that the above content can help you better evaluate the wear resistance of the cheek plate of the jaw crusher. If you have any questions about the wear resistance of the cheek plate or need further information, please feel free to contact us at any time.