How to distinguish whether the excavator bucket teeth are seriously worn

Identifying whether the excavator bucket teeth are seriously worn can be done in the following ways:

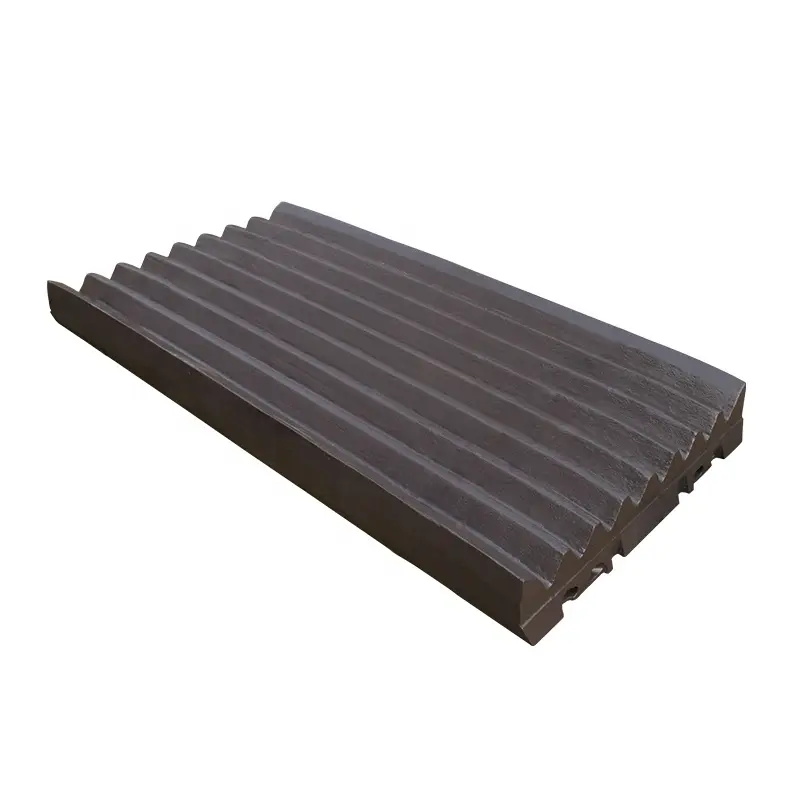

Look for wear marks

- Surface scratches and furrows: Carefully inspect the surface of the bucket teeth, if there is a clear furrowed scratch, and the scratch is deep, indicating that the bucket teeth have experienced a longer period of wear. This scratch is usually caused by friction between the teeth of the bucket and hard materials.

- Blunt tooth tip: The tooth tip of the bucket teeth is originally sharp, if the tooth tip part becomes smooth or blunt, or even obvious gaps, which indicates that the wear of the bucket teeth has been more serious.

Measurement size change

- Thickness reduction: Use calipers and other measuring tools to measure the thickness of the bucket teeth. If the thickness of the bucket teeth is reduced by 10%-15% compared with the new bucket teeth, it indicates that the wear has been more serious. For example, if the thickness of the bucket teeth was originally 10mm and is now reduced to about 8.5mm, it may need to be replaced.

- Length reduction: Similarly, measure the length of the bucket teeth, if the length is significantly shortened, it also indicates serious wear. The reduction of length will affect the digging efficiency and stability of the bucket teeth.

Check for wear

- Uneven wear: If the wear of the bucket teeth is not uniform, some parts are seriously worn and other parts are relatively good, which may lead to uneven forces in the use of the bucket teeth, increasing the risk of breaking the bucket teeth.

- Seat wear: In addition to the bucket teeth themselves, the wear of the seat is also very important. If the tooth base is worn off by 10%-15%, it is recommended to replace the tooth base, because excessive wear of the tooth base will cause the gap between the tooth and the tooth base to increase, change the force point of the tooth, so that the tooth is more likely to break.

Use testing equipment

- Image processing technology: By collecting the video data of the bucket teeth and using image processing technology to analyze the video data, the wear degree of the bucket teeth can be detected. For example, using computer vision techniques such as edge detection, color segmentation and shape analysis, the wear of bucket teeth can be automatically identified.

- Built-in detection device: some bucket teeth are equipped with a detection device, when the bucket teeth wear to the critical point, the pressure sensing department will be squeezed, so that the circuit is connected, the prompt department is lit up, reminding the operator to replace the bucket teeth in time.

Observe the use

- Reduced mining efficiency: In the actual use process, if the excavation efficiency of the excavator is significantly reduced, more force is needed to scoop up the material, which may be caused by serious wear of the bucket teeth.

- Loose or falling teeth: If the bucket teeth are loose or falling off, it is usually a sign of serious wear. Loose bucket teeth are easy to fall off during the excavation process, which not only affects the efficiency of the operation, but also may damage other equipment.

Through the above methods, it can be more accurate to identify whether the excavator bucket teeth are seriously worn. Timely discovery and replacement of the seriously worn bucket teeth is of great significance for ensuring the normal operation of the excavator and extending the service life of the equipment.