01

How Much Do You Know About The "Heart" Of The Cone Crusher?

2024-08-26

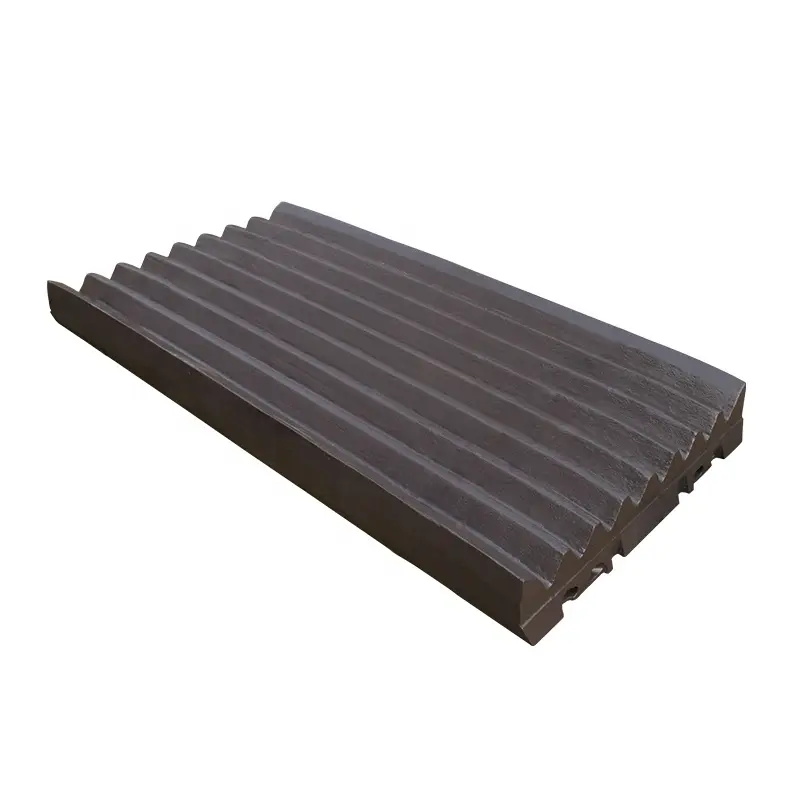

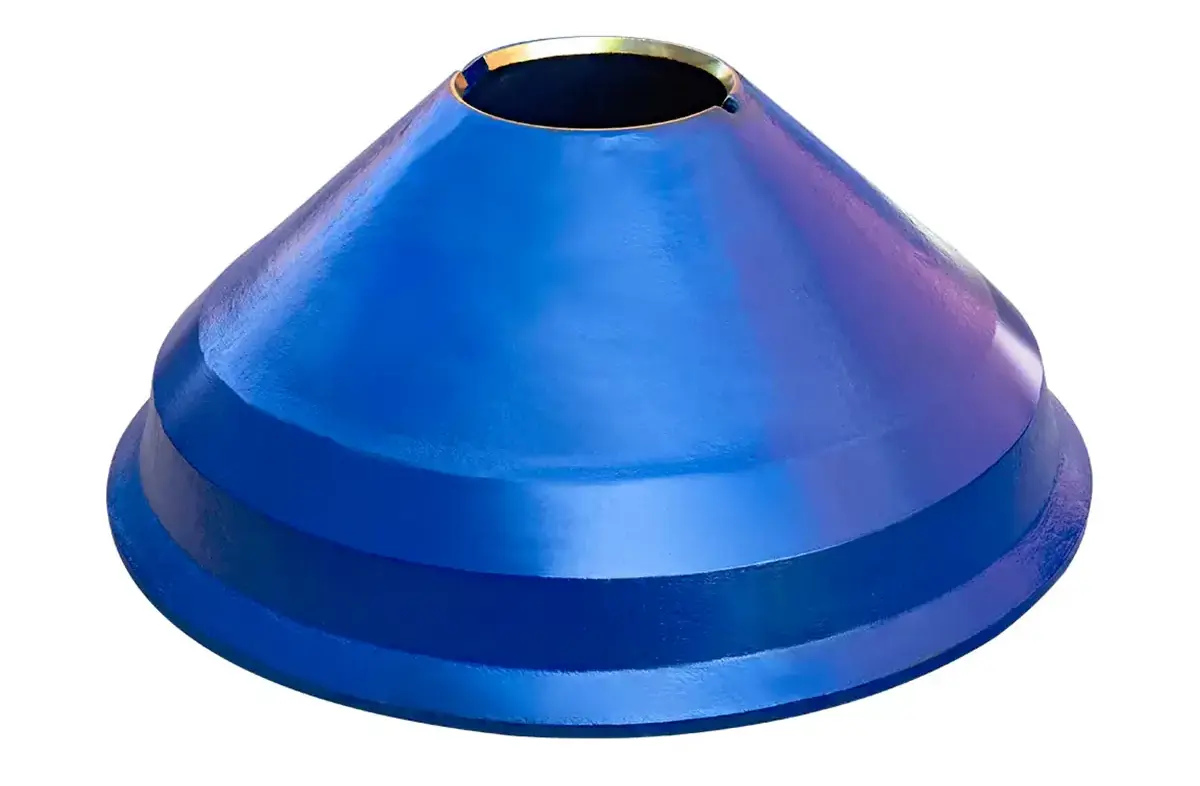

The crushing wall and rolling wall of the cone crusher are direct contact parts and are also the main wear-resistant parts of the cone crusher. They can be said to be the heart of the cone crusher. In a cone crusher, the crushing chamber consists of a cavity between two liners: the cavity between the rolling wall (fixed cone liner) and the crushing wall (moving cone liner). This article mainly focuses on how long can the cone crushing wall and rolling wall be used? What factors affect its lifespan? How to replace? The following analysis was performed. Lifetime When the cone crusher is running, the crushing wall moves along a trajectory away from the rolling and grinding wall. The material is squeezed and impacted multiple times by the crushing wall (moving cone) and the rolling and grinding wall (fixed cone), and part of the material will be discharged from the opening.

After the broken wall and grinding wall are used for a period of time, they will inevitably wear out. Generally speaking, the crushing wall and grinding wall of a cone crusher can be used for 6 months, and some people need to replace it after 2-3 months of use. Since its service life is affected by various factors, there will be varying degrees of wear and tear. When the thickness of the broken wall and frosted wall of the cone is worn to two-thirds or cracked, and the exhaust port is increased beyond adjustment, it needs to be replaced. Factors that affect the service life Generally speaking,

the factors that affect the crushing effect and service life of the crushing wall and the rolling and grinding wall are:

stone powder content and stone humidity, stone hardness and particle size, feeding method, the quality of the crushing wall and the rolling and grinding wall itself, etc. .

1. Stone powder content and stone humidity When the cone crusher is working, if the stone powder content and humidity of the material are high, it will easily adhere to the crushing wall and rolling wall during crushing. Over time, it will not only reduce production efficiency, but also corrode the crushing and rolling walls, reducing their service life. For materials with high stone powder content, they should be screened before crushing to avoid excessive fine powder; for materials with high humidity, measures such as natural drying or mechanical drying should be taken before crushing.

2. The hardness and particle size of the stone. According to the hardness of the material crushed by the cone crusher, the degree of wear of the crushing wall and the mortar wall is also different. The higher the hardness of the material, the more difficult it is to crush, the greater the impact load on the crushing wall and the mortar wall, and the shorter the service life; when the hardness of the ore is the same, the larger the particle size of the ore entering the crushing chamber, the more serious the liner wear, and the shorter the service life. .

3. Feeding method The feeding method of the cone crusher also has a certain impact on the service life of the crushing wall and frosted wall. If the feeding device of the cone crusher is improperly installed or too much material enters the crushing chamber, it will lead to uneven feeding, material blockage in the crushing chamber, etc., causing excessive unilateral force on the frosted wall of the crushing wall, increasing ore cutting wear, and causing serious damage. Lining board, reducing service life. 4. The quality of the crushing wall and rolling grinding wall itself is the most important factor among all factors. High-quality wear-resistant accessories have higher requirements on the surface of castings. Castings are not allowed to have casting defects such as slag inclusions, sand inclusions, cold insulation, pores, shrinkage holes, shrinkage and looseness, and lack of flesh.

The crushing walls and rolling walls of cone crushers on the market are generally made of high manganese steel. With the continuous development of science and technology, the performance of wear-resistant materials is also constantly improving. Generally speaking, materials that can quickly harden the surface under impact load, form a hard wear-resistant surface, and maintain the original toughness of the internal metal should be selected to increase the service life of the crushing wall and rolling wall.

How to Replace The general process of replacing the crushing wall and rolling wall of a cone crusher is as follows:

1. Check first. Check the retaining cone, adjusting ring, locking thread, counterweight and counterweight guard for wear.

2. Reinstall. If the wear is serious, replace it with a new one and then install the liner to reduce the time of secondary replacement and disassembly, saving time and energy. 3. Check again. After installing the liner, check whether the center of the liner is correct, otherwise the liner will collide during operation, causing serious wear of the liner. Rolling mortar wall replacement method: The rolling mortar wall can be replaced on site.

Rotate the adjusting screw sleeve installed on the upper frame (note the counterclockwise rotation), remove the upper chamber hopper assembly, and use lifting equipment to lift the adjusting screw sleeve. After removing the adjusting nut support plate bolts, the rolled mortar wall can be removed for replacement. When assembling, clean the outer surface, adjust the thread surface of the screw sleeve, apply butter, and install and fix in reverse order. Note: There is a U-shaped screw on the rolling wall, the zinc alloy is injected into the adjustment ring and tightly combined. When newly installing or replacing the rolled wall, check the tightening condition after 6-8 hours of work and tighten the U-shaped screws again.

Broken wall replacement method:

Broken walls can be replaced on site. Hang the spindle components and place them on a solid support platform. Be careful not to damage the cone and spherical surface. Use a cloth to block all oil holes to avoid dust and impurities from entering. Remove the distribution plate, locking nuts, locking washers, and fusible gaskets. , two lifting lugs are welded to the part at a distance of 180° from the boss, and the broken wall can be lifted out. The new wall can also be installed at a distance of 180°. The two lifting lugs are also welded to the same part, and then installed in the opposite order, and finally cut off when completed. Two lifting lugs. Note: The cone crushing wall is fixed on the cone with a cone head, and zinc alloy is cast between the two. After the newly installed or replaced cone crushing wall has been in operation for 6-8 hours, check the tightening condition, and tighten it immediately if it is loose. During the operation of the cone crusher, it should be noted that the materials in the equipment must meet the crushing requirements, the feed must be uniform, the ore must be fed in the middle of the distribution plate, and the materials cannot directly interact with the crushing wall and rolling wall.

Zhejiang Yurong Industrial Co., Ltd. was established in 1985 and is located in Wuyi, Jinhua, Zhejiang. It is a wear-resistant parts manufacturer specializing in crushing equipment. It is the unit that presided over the revision of the national standard GB/T5680-2010 "Austenitic Manganese Steel Castings".