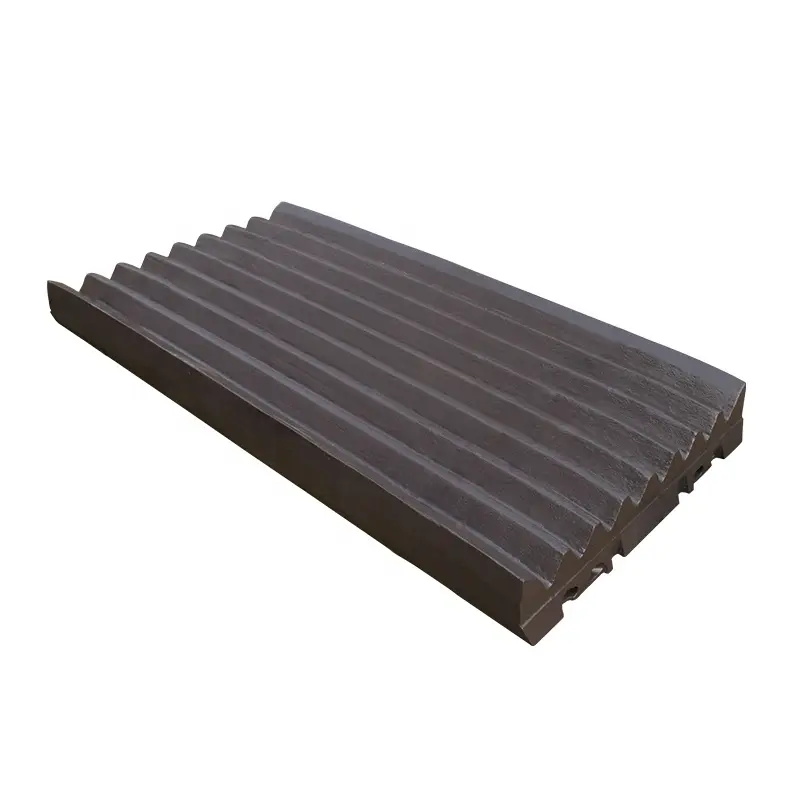

Daily maintenance and maintenance of buffer board

As a key component in mechanical equipment, the buffer plate is mainly used to absorb impact force and reduce vibration, so as to protect other parts of the equipment from damage. Proper maintenance and maintenance can not only extend the service life of the buffer board, but also ensure the efficient operation of the equipment. Here are some practical care and maintenance tips:

First, regular cleaning

The buffer board can accumulate dust, oil and other impurities during use, which can increase wear and reduce its performance. It is recommended to periodically use a soft cloth or brush to remove dust and dirt from the surface. For stubborn stains that are difficult to clean, you can use a mild cleaning agent to wipe, but be careful to avoid the use of corrosive chemicals.

Second, check the seals

The seal is an important part of the buffer plate, and its integrity directly affects the performance of the buffer plate. Check the seals regularly for signs of aging, damage or deformation, and replace the seals immediately once a problem is found. This not only prevents oil leakage, but also ensures the damping effect of the buffer plate.

3. Keep lubricated

Proper lubrication can significantly reduce buffer plate wear. Apply suitable lubricating oil or grease regularly to the friction area of the buffer plate as recommended by the manufacturer. This not only reduces friction, but also extends the life of the buffer plate.

Four, check the connection

The connecting parts of the buffer plate (such as bolts and nuts) may become loose due to vibration during use. Check the tightness of these connectors regularly to ensure that they are firm and reliable. Loose connectors will not only affect the performance of the buffer board, but may also cause equipment failure.

5. Avoid overload operation

Overload operation will increase the wear speed of the buffer plate and shorten its service life. During use, the equipment should be avoided in a high load state for a long time. If the device needs to handle heavy loads, you are advised to use a buffer board of a higher specification.

6. Check the working status regularly

The key to prevent faults is to check the working status of the buffer board regularly. Observe whether the buffer plate has abnormal vibration or noise, and check whether the surface has obvious damage or deformation. If the problem is found, it should be repaired or replaced in time.

7. Storage conditions

When not in use, the buffer plate should be stored in a dry, clean environment to avoid moisture or exposure to extreme temperatures. Good storage conditions can reduce the natural aging of the buffer board and extend its service life.

Through these daily maintenance and maintenance measures, the wear of the buffer plate can be effectively reduced, its service life can be extended, and the efficient operation of the equipment can be ensured.