Common failure analysis and elimination methods of roller press

The output of the roller press is too large, but the quality of the extruded material is reduced

1. The roll gap is too large, and the pressure does not match the feeding amount and the thickness of the cake.

2. The pressure of the hydraulic system is too low to achieve the predetermined crushing effect.

3. The adjustment plate of the feeding device is adjusted too low, so that the extrusion crushing force exerted by the hydraulic system does not fully act on the extruded material.

4. The gap between two extrusion rollers is too large.

5. The bottom liner of the side baffle plate is excessively worn.

Elimination method

1. Adjust the feeding insert plate to increase the insertion depth, so that the roll gap is reduced and the passing amount is reduced.

2. Adjust the pressure of the roller press to match the feeding amount and the thickness of the cake.

3. Adjust the working pressure of the system again and raise the adjusting plate of the feeding device.

4. Handle the small problem of the main electrical flow, and appropriately reduce the roll gap between the two extrusion rollers.

5. Replace the bottom liner of the baffle; Appropriately reduce the roll gap between the two extrusion rollers.

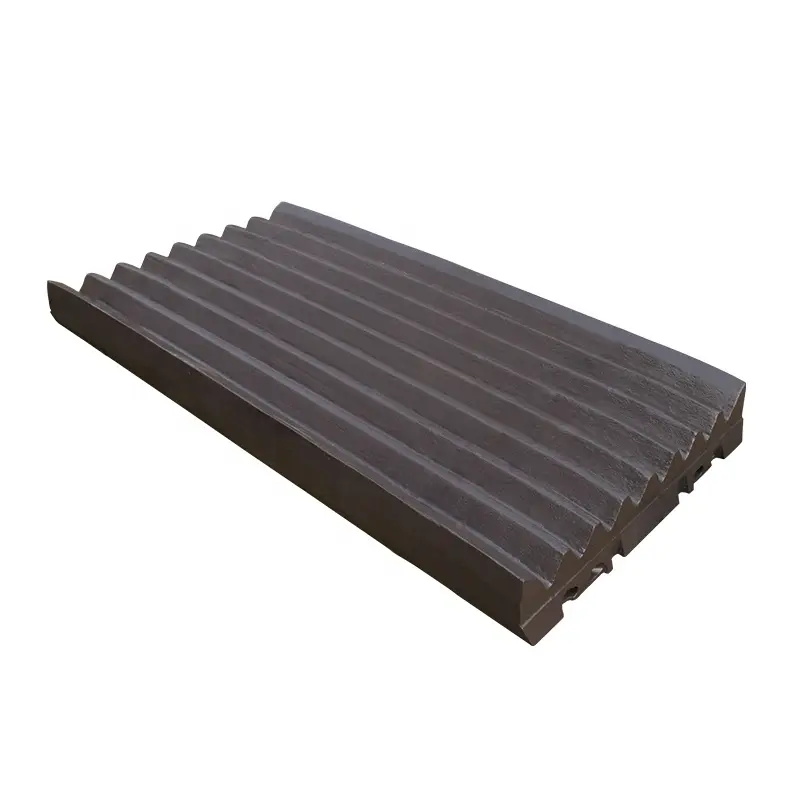

Cause of damage of extrusion roll surface

1. Metal debris is mixed into the material fed into the roller press.

2. Materials, corrugated forms, heat treatment methods, surfacing technical measures and technical quality of the wear-resistant layer of roll surfacing.

Elimination method

1. Install iron remover and metal detector.

2. Select high quality extrusion rolls to ensure the quality of surfacing welding.

Causes of floating roll tilt of roller press

1. Unstable material quality.

2. Uneven material flow.

3. The hydraulic system two accumulators, the hydraulic cylinder on both sides of the oil filling speed is not equal, so that the pressure on both sides is unbalanced.

Elimination method

1. Control the mixing ratio of granular materials with different particle sizes.

2. Solve the problem of uneven material flow.

3. Configure the hydraulic cylinder with the same specifications and accuracy, and replace or repair the energy accumulator if it is damaged.

Cause of alarm of roll gap detection

1. There is a large hard foreign body in the roll gap.

2. The feed insert plate is adjusted too large.

3. System operation error may also cause alarm.

Elimination method

1. If foreign bodies are identified, stop the vehicle immediately and discharge them.

2. If the hydraulic system is not pressurized due to operation error, the hydraulic system should be checked.

3. If the roll gap is too large and the cake is too thick, the insert plate should be reduced.

Cause of motor trip and overload

1. Roll press trip, there is not extruded large foreign matter into (such as steel ball, etc.).

2. The roller press is overloaded, because the feeding amount is too large or the roller rolling gap is too small.

Elimination method

1. Stop the machine to remove foreign bodies or stop the hydraulic pump to make the hard objects fall automatically and be removed manually.

2. Adjust the feeding amount and the working pressure of the hydraulic pump.