Can a hammer crusher be used to break cement blocks?

General cement block is stone, sand, cement and other building aggregates mixed by water condensation, its size will be based on the building demolition method, the larger in one meter, after the appropriate crusher broken, you can re-screen a variety of granular aggregate.

Is it possible to break cement blocks with a hammer crusher? The answer is yes. Not to mention the many advantages of the hammer crusher, the function of only one machine and two machines is not comparable to other crushing equipment. Hammer crusher has a better processing technology, according to different cement, stone properties, to meet the processing needs of different cement and hundreds of ore materials.

1, the output design of the hammer crusher is adjustable grate device, can be freely adjusted according to the user's production needs, uniform discharge particle size, excellent particle shape, good shaping effect, the quality of the finished product is particularly high, the crushed cement material can also be used for refractory materials, construction, metallurgy, electric power, chemical and cement industries, high application value.

2, energy consumption low hammer crusher using the role of the hammer head, to achieve a principle of impact to promote the cement material broken, through the repeated process, so that the cement material is broken to the required particle size. The overall design of the equipment is more advanced, stable operation, the whole power of the system is small, the crushing ratio is large, the production consumption is greatly reduced, saving more than 40% than the conventional three-stage crushing, reducing energy consumption, and improving the production efficiency of the equipment.

Advantages of hammer crusher:

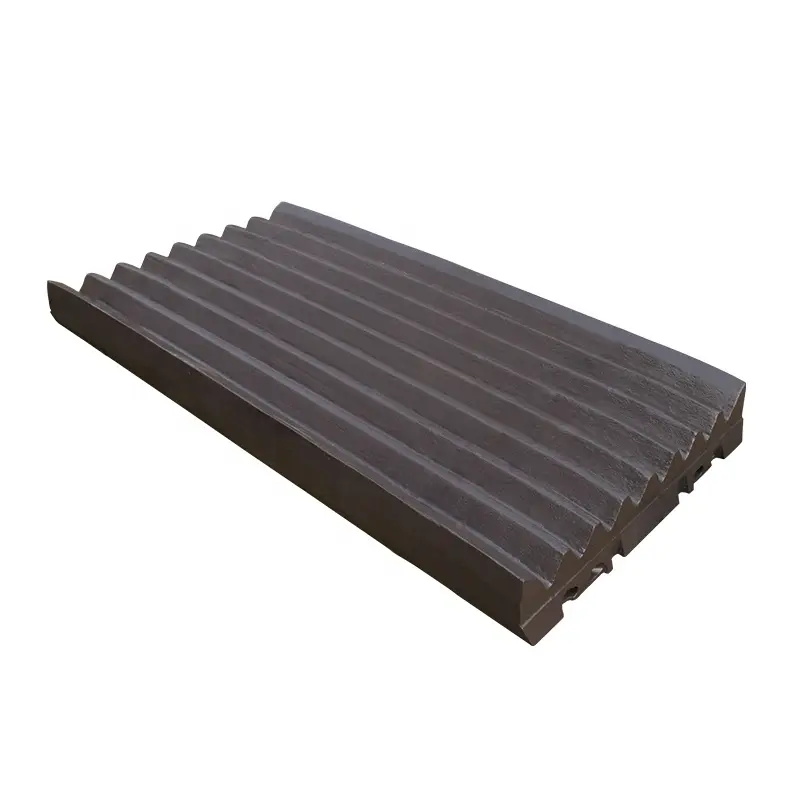

1, a molding hammer crusher using the inertia impact of the hammer head to break cement blocks, the whole set of hammer flexible combination, can be the block cement a molding, no need for secondary crushing, simplifying the crushing process, reduce production costs, save the user's investment.

2, reliable quality selection of alloy material production, mature and stable process, fine workmanship, hammer crusher quality, performance, in the operation process is not easy to fail, long service life of equipment.

3, green environmental protection adopts the energy-saving design concept, reduces the noise of the equipment, reduces the overflow of dust, the impact of the production process on the environment is relatively small, coupled with the role of external dust removal noise reduction and spray device, so that the production process meets the requirements of environmental protection.

4, high degree of automation advanced and reasonable equipment design, simple and convenient operation, high degree of automation, reduce site operators, modular design can achieve rough, medium and fine processing methods, improve production efficiency, large processing capacity.