Advantages of the jaw plate and the difference between castings and forgings

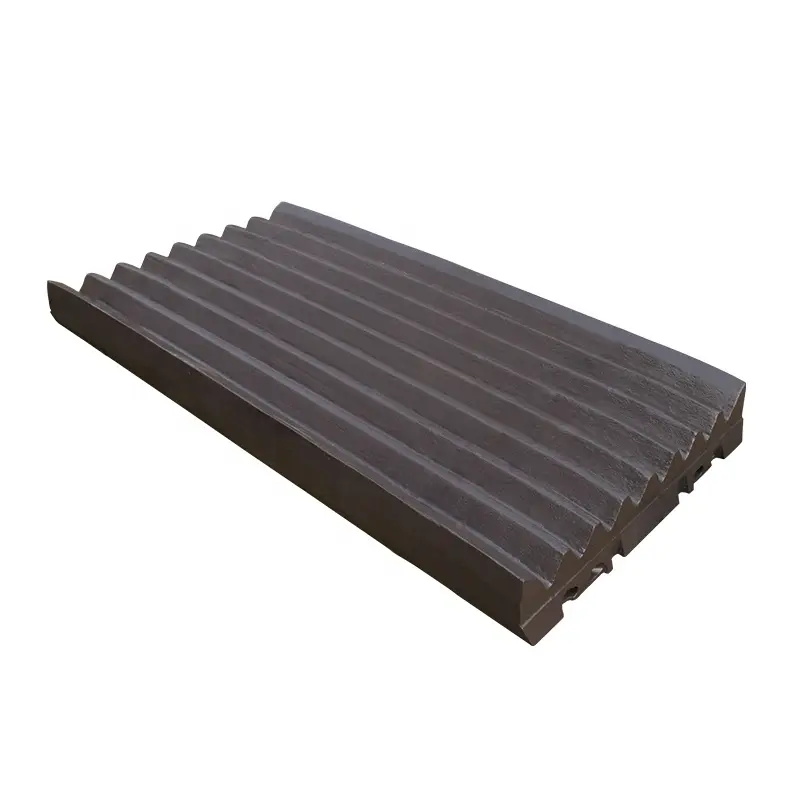

Jaw plate is the main component of jaw crusher: dynamic jaw plate, static jaw plate, according to the type of jaw crusher is not the same, there are a variety of types of scale, red apple jaw plate selection of high manganese steel and ultra-high manganese steel raw materials, applicable to various specifications jaw crusher jaw plate.

The service life of the jaw crusher is determined by the larger consumption of the jaw plate, the selection of high hardness, wear resistance, strong toughness of the jaw plate, it will extend the service life of the crusher. The E plate is made of high manganese steel, although there are some shortcomings, it is undeniable that the high manganese steel E plate has irreplaceable advantages, and the high manganese steel E plate is still in an important position. The most important feature of high manganese steel is that under the conditions of strong impact and extrusion, the work hardening phenomenon occurs rapidly on the surface, so that the heart still maintains good toughness and plasticity of austenite while the hardened layer has good wear resistance. This is other materials can not. High manganese steel castings mostly adopt sand molding process. Sand casting is widely promoted because of its mature technology and high production efficiency.

Now a lot of equipment and accessories are made of castings or forgings, so when to use castings, when to use forgings? Next, what are the differences between castings and forgings, and what are their respective characteristics?

Forgings are metal objects in which pressure is applied to shape a desired shape or suitable compression force through plastic deformation. This force is typically achieved through the use of a hammer or pressure. The forging process builds a refined granular structure and improves the physical properties of the metal. In the practical use of parts, a correct design can make the particle flow in the direction of the main pressure. Castings are metal forming objects obtained by various casting methods, that is, the smelted liquid metal is injected into the prepared mold by pouring, pressing, inhaling or other casting methods, and the objects with a certain shape, size and performance are obtained after cooling.

The simple understanding is: forging: use the furnace to burn the workpiece red with pressure machinery such as gas hammer, press, etc., to change the workpiece into the required shape. Casting: Burning metal into hot metal in a stove. Pour into a pre-made mold and let cool to get the desired shape. Forging is solid metal, casting is liquid metal. In addition, the mechanical properties and forming methods of castings and forgings are not the same, forgings after secondary work hardening, dense organization, non-directional mechanical properties, better than castings; The casting is melted by the melting furnace, poured into the model, and cooled to form; Forgings are formed by pressing repeatedly under pressure by a press.