Note: High yield and high efficiency start from the correct operation!

Excavator Teeth: Dig Deeper, Work Smarter

The treatment of full grinding of ball mill is briefly introduced

The ball mill liner has 3 functions, 8 classifications and 10 installation requirements

You know the track plate

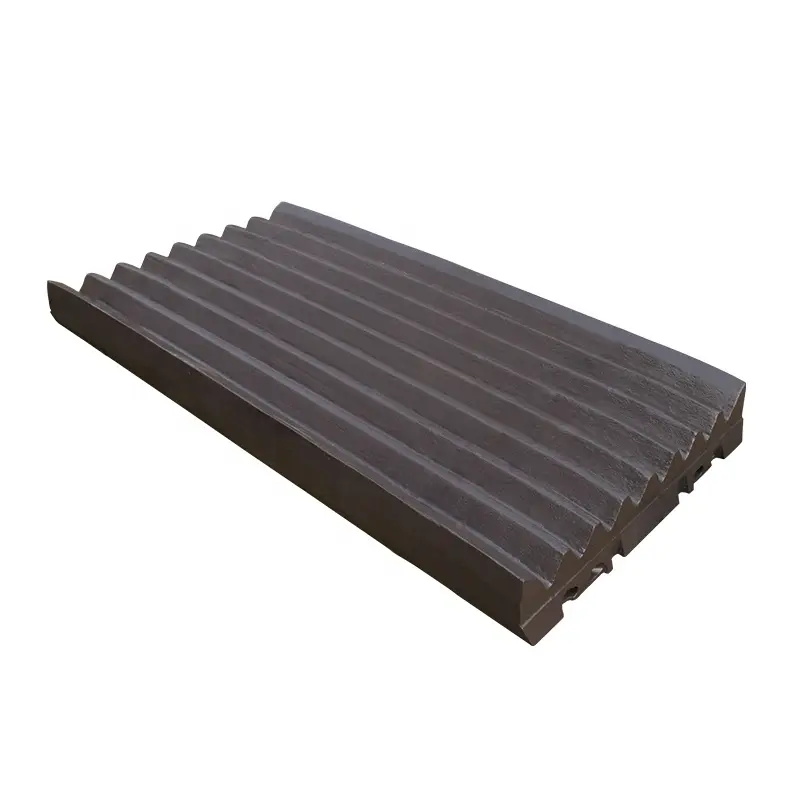

What is the role of the impact crusher's impact plate?

MINEXPO2024 International Mining Exhibition Grandly Opened In Las Vegas, USA

On September 24, 2024, the grand event of the global mining industry, MINEXPO2024 International Mining Exhibition, opened grandly in Las Vegas, USA. Zhejiang Yurong Industrial Co., Ltd. brought cutting-edge products to the booth at 3150 Paradise Road Las Vegas, NV 89109. We sincerely invite colleagues from the global mining industry to visit and seek new opportunities for mining development.

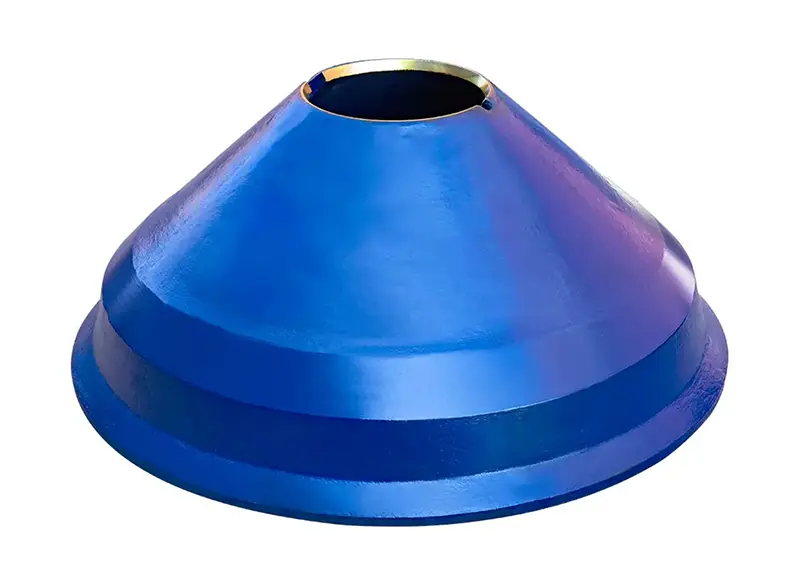

What Are The Wearing Parts Of The Cone Crusher And How Long Do They Need To Be Replaced?

Among mining equipment, cone crushers are crushing equipment with high efficiency, low energy consumption and good quality, and are suitable for materials with higher hardness. In the daily rock breaking work of cone crushers, it is inevitable for us to wear parts. So what are the wearing parts of the cone crusher? What impact will it have on the cone crusher? How to use the cone crusher to "extend its life"?

How Much Do You Know About The "Heart" Of The Cone Crusher?

The crushing wall and rolling wall of the cone crusher are direct contact parts and are also the main wear-resistant parts of the cone crusher. They can be said to be the heart of the cone crusher. In a cone crusher, the crushing chamber consists of a cavity between two liners: the cavity between the rolling wall (fixed cone liner) and the crushing wall (moving cone liner). This article mainly focuses on how long can the cone crushing wall and rolling wall be used? What factors affect its lifespan? How to replace? The following analysis was performed. Lifetime When the cone crusher is running, the crushing wall moves along a trajectory away from the rolling and grinding wall. The material is squeezed and impacted multiple times by the crushing wall (moving cone) and the rolling and grinding wall (fixed cone), and part of the material will be discharged from the opening.

Factors Affecting The Life Of The Crushing Wall And Rolling Mortar Wall And Their Replacement Methods

In a cone crusher, the crushing cavity is formed by the cavity between two lining plates: the cavity between the rolling mortar wall (fixed cone lining plate) and the crushing wall (moving cone lining plate). It can be seen that the crushing wall and the rolling mortar wall are parts that directly contact the material and are also the main wear-resistant parts in the cone crusher. This article answers questions about the service life of the crushing wall and the rolling mortar wall of the cone crusher and its influencing factors.