-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Understanding Cone Crusher Components is vital for maximizing operational efficiency. Each component plays a unique role in the crushing process. These parts include the mantle, concave, and various other components that work together.

The mantle, for instance, is crucial for the actual crushing. It comes into direct contact with the material. The design and wear of the mantle can impact the overall performance significantly. Meanwhile, the concave holds the aggregate in place and shapes the final product. Neglecting maintenance of these components can lead to inefficiency.

An overlooked cone crusher component can lead to reduced output. It’s essential to grasp how each piece functions. Regular checks can prevent unexpected failures. Awareness of these parts may seem daunting, but it’s necessary. Recognizing signs of wear and tear can enhance longevity. In essence, understanding Cone Crusher Components holds the key to efficient operations and productive results.

The cone crusher plays a vital role in the mining and aggregate industries. It crushes materials into smaller, manageable pieces. This process is essential for further processing or selling. In quarries and mines, efficiency is crucial. A well-functioning cone crusher can significantly enhance production rates.

Understanding the components of a cone crusher can boost its efficiency. Each part has a specific purpose, such as handling the crushing process or managing the flow of materials. If any component is faulty, it can lead to bottlenecks. A damaged cone liner, for example, may affect the product size and output.

Maintenance is often overlooked. Regular checks should focus on wear parts and lubrication. Ignoring these can result in costly downtime. Operators sometimes misjudge the signs of wear, leading to unexpected failures. Inattention to detail can disrupt operations. Assessing the cone crusher's performance should be a priority. It’s not just about having the equipment; it’s about knowing how to keep it running well.

Understanding the key components of cone crushers is essential for optimal efficiency. The main components include the mantle, concave, and the eccentric. Each part plays a specific role in the crushing process. The mantle is the moving part that crushes material against the concave. This action creates a compressive force crucial for breaking down rocks.

Another vital component is the hydraulic system. It controls the crusher's closed-side setting. This setting can affect product size and output. An appropriate closed-side setting improves the machine's performance. The feed opening and discharge also significantly influence throughput.

**Tip:** Regularly inspect these components for wear. This practice helps prevent unexpected breakdowns. Maintaining proper alignment between the mantle and concave can enhance crushing efficiency. Listen for unusual sounds during operation. Any strange noises may indicate a problem needing attention. Remember, even small deviations can lead to significant inefficiencies over time.

| Component | Function | Importance |

|---|---|---|

| Bowl | Holds the crushing cavity and allows the material to be crushed between it and the mantle. | Ensures proper sizing of materials, enhancing overall efficiency of the crushing process. |

| Mantle | The moving component that compresses the material against the bowl. | Directly impacts the reduction ratio, crucial for achieving desired output size. |

| Cone | The structure that supports the mantle and transmits the force from the motor. | Essential for structural integrity and optimal functioning of the crushing system. |

| Drive System | Includes the motor and other components that provide power to the cone crusher. | Vital for maintaining proper operational speed and efficiency of crushing operations. |

| Hydraulic System | Controls the operation of the cone, including adjustment and overload protection. | Enhances safety and efficiency by allowing for adjustments without manual intervention. |

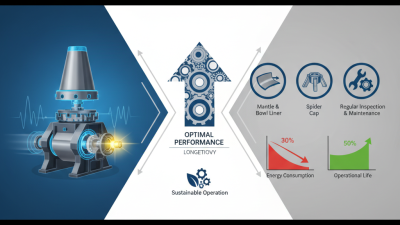

Cone crushers are vital in the mining and aggregate industries. Understanding how their components work can significantly enhance performance. Each part, from the mantle to the bowl liner, plays a key role. The shape and material of these components directly affect the crushing efficiency. Industry reports indicate that an optimized material choice can increase service life by up to 30%.

When components wear out or function poorly, overall efficiency declines. For instance, a worn liner can lower throughput by 25% or more. This impacts production rates and raises operational costs. Tracking wear patterns can provide insights. Regular inspections can prevent significant performance drops.

Moreover, the gap setting between components needs to be precise. If set too wide, it leads to an increase in fines. Too narrow, and the potential for blockages rises. Both scenarios highlight the importance of attention to detail. Even small adjustments can lead to substantial changes in performance metrics. Understanding these aspects is necessary for maintaining efficiency in operations.

Proper maintenance practices are vital for optimal cone crusher operation. Regular inspections help identify wear and tear on internal components. It is essential to check the lubrication system frequently. Insufficient lubrication can lead to increased friction and overheating.

Cleaning the cone crusher is another critical task. Dust and debris can accumulate, affecting performance. Operators should remove buildup around the cone and ensure all vents are clear. This simple step improves airflow and cooling, enhancing operational efficiency.

Operators must not overlook the importance of monitoring performance metrics. Tracking output and efficiency ensures that any decline in productivity is addressed. A fall in performance may indicate underlying issues needing immediate action. Reflecting on these metrics can guide better maintenance strategies. Regularly revisiting maintenance schedules is crucial. There may be times when they need adjustments to meet specific operational demands.

Understanding cone crusher components is key to maintaining efficiency. Issues often arise with different parts. Problems can lead to downtime and increased operational costs. Common components may include the mantle, bowl liner, and eccentric bushings. Each has its role, and if one fails, performance can decline.

Regular inspections are essential. Watch for wear and tear on the mantle and liner. If they’re worn down, replace them promptly to avoid further damage. Misalignment can cause excessive vibration. This may affect product quality and machine lifespan. Always adjust the settings based on your material's characteristics.

Tips: Check the lubrication levels regularly. Inadequate lubrication can lead to overheating and failures. Clean the cooling system to keep the machine running smoothly. A clean environment helps to prevent debris from entering the system. Addressing these small issues can prevent larger problems down the line. Remember, every part matters. Neglect can lead to costly repairs and delays.

This chart illustrates the efficiency levels associated with various components of a cone crusher, highlighting their impact on overall performance. Understanding these metrics is crucial for troubleshooting and optimizing operations.