-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the ever-evolving landscape of the mining and construction industry, the Gyratory Crusher stands out as a pivotal piece of equipment that has significantly enhanced productivity and efficiency. According to Dr. John Smith, a renowned expert in material processing technologies, "The Gyratory Crusher is indispensable for large-scale operations, offering unparalleled crushing capabilities and cost-effectiveness." This statement underscores the essential role that Gyratory Crushers play in modern processing plants, where the demand for high-performance machinery continues to rise.

As we delve into the top ten benefits of Gyratory Crushers in 2023, it becomes clear that these machines can streamline processes, reduce operational costs, and improve safety on-site. With their unique design and superior crushing techniques, Gyratory Crushers not only handle a vast array of materials but also cater to the increasing need for sustainability in production methods. The following discussion will explore how these benefits manifest in real-world applications, providing insights that can guide industry professionals in making informed decisions regarding their equipment investments. Embracing the advancements in Gyratory Crusher technology is not just a strategic choice; it is a step toward securing a competitive edge in the market.

Gyratory crushers play a pivotal role in the mining industry, primarily used for crushing large quantities of ore into manageable sizes for further processing. Characterized by their conical shape, these machines utilize a combination of compressive force and shear motion to break down hard materials effectively. According to a recent industry report by Technavio, the global gyratory crusher market is expected to grow at a CAGR of over 5% during the forecast period from 2021 to 2025, driven by the increasing demand for minerals and ores in various sectors.

The efficiency of gyratory crushers is unmatched, making them a preferred choice for large-scale mining operations. Their design allows them to handle heavier loads and deliver finer particle sizes, significantly enhancing operational productivity. A study by Global Mining Review highlighted that these crushers can achieve throughputs exceeding 10,000 tons per hour, which is essential for large mines seeking to maintain high levels of output. Furthermore, with advancements in technology, newer models offer features like automation and energy efficiency, aligning with industry trends towards sustainable mining practices. This positions gyratory crushers not only as tools for material reduction but also as integral components in the quest for improved resource extraction methodologies.

| Benefit | Description | Impact on Mining |

|---|---|---|

| High Efficiency | Gyratory crushers provide high throughput rates and efficient rock destruction. | Increases productivity and reduces processing time. |

| Durability | Designed to withstand heavy use and extreme environments, ensuring long service life. | Minimizes downtime and maintenance costs. |

| Better Control | Offers precise control over the size of crushed material through adjustable settings. | Improves the quality of the final product. |

| Less Noise | Operates quieter than other types of crushers, reducing noise pollution. | Enhances working conditions for operators. |

| Versatility | Can handle a wide range of material types and sizes. | Adaptable to various mining applications. |

| Eco-Friendly | Designed to be more energy-efficient, reducing environmental impact. | Supports sustainable mining practices. |

| Reduced Operational Costs | Lower energy and maintenance costs contribute to overall operational savings. | Enhances the profitability of mining operations. |

| Improved Safety | Modern designs emphasize operator safety with better shielding and control systems. | Reduces the risk of accidents on site. |

| Ease of Operation | User-friendly controls simplify the operation process. | Allows for quick training of new operators. |

| Long Lifespan | High-quality materials and construction lead to extended equipment lifespan. | Represents a wise investment in mining machinery. |

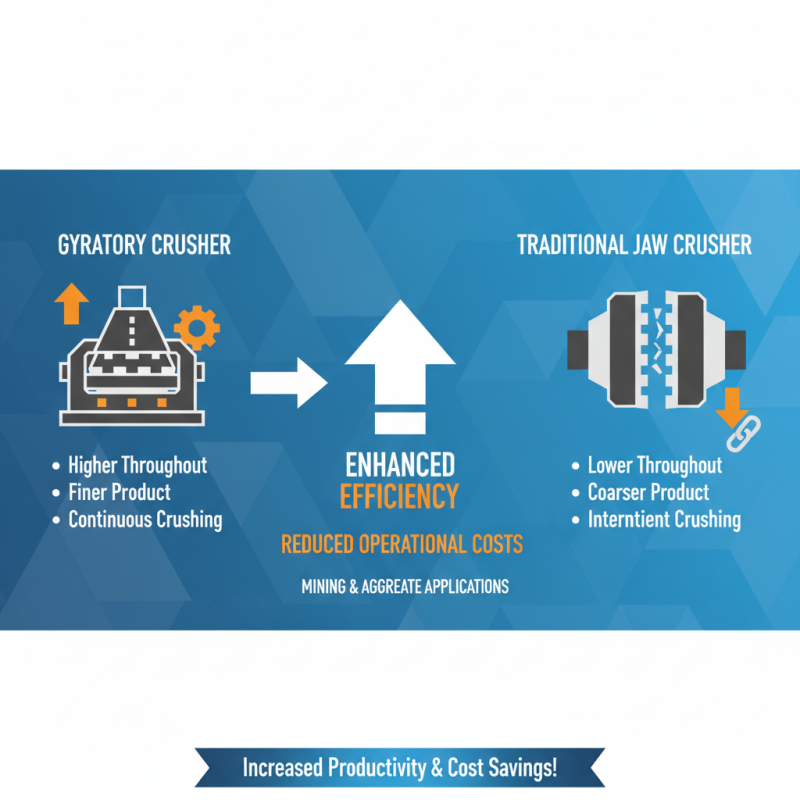

Gyratory crushers are renowned for their enhanced efficiency, which is one of the primary reasons they are favored in various heavy-duty mining and aggregate applications. These machines utilize a circular motion, enabling higher throughput rates compared to traditional jaw crushers. This design not only allows for larger volumes of material to be processed but also ensures a finer product size, as the crushing action is more continuous and automated. Operators can expect reduced operational costs and improved productivity as a result of this efficiency.

Furthermore, the high throughput of gyratory crushers makes them ideal for large-scale operations where time and output are critical factors. The consistency of the crushing process minimizes variations in output sizes, leading to better quality aggregates. Additionally, the ability of these crushers to handle a wide range of materials, from hard minerals to softer rocks, showcases their versatility in various applications. This adaptability enhances their performance, making them a significant asset in any large-scale production environment where maximizing efficiency is paramount.

When it comes to optimizing productivity and efficiency in the mining and aggregate industries, gyratory crushers stand out for their significantly lower operational costs when compared to traditional crushers. These machines are designed to handle large volumes of material with minimal downtime, which directly contributes to cost savings. The efficient compressive crushing technique utilized by gyratory crushers not only minimizes energy consumption but also reduces wear and tear on components, ultimately lowering maintenance and replacement costs.

Moreover, the advanced engineering of gyratory crushers allows for a streamlined operation that enhances material flow and reduces bottlenecks in the crushing process. With fewer required adjustments and simpler serviceability, operators can rely on these machines to run smoothly without incurring the steep maintenance expenses often associated with older models. This operational efficiency, combined with their ability to process harder materials, makes gyratory crushers an economical choice for businesses aiming to stay competitive in a challenging market.

This chart illustrates the operational costs associated with Gyratory Crushers compared to Traditional Crushers. As seen, Gyratory Crushers demonstrate significant savings in operational costs across different parameters.

Gyratory crushers are increasingly recognized for their reduced environmental impact, a critical factor in the mining and aggregate industries where sustainability is becoming paramount. According to a report by the International Council on Mining and Metals, the mining sector is responsible for up to 4-7% of global greenhouse gas emissions. By incorporating advanced gyratory technology, operations can significantly lower their carbon footprint. These crushers are designed for efficiency, utilizing less energy per ton of material processed compared to traditional crushers. Studies indicate that operators can achieve up to a 20% reduction in energy consumption, which not only curtails emissions but also lowers operational costs.

Furthermore, gyratory crushers contribute to waste reduction by effectively managing materials with high efficiency and lower operational downtime. The advanced design of these machines allows for the processing of larger volumes of rock with fewer equipment failures, resulting in decreased waste production. The Eco-Efficiency report by the World Economic Forum highlights that operations utilizing high-efficiency crushing equipment can reduce their waste output by as much as 30%. This shift not only helps companies meet stricter environmental regulations but also aligns with the broader global movement towards greener practices in resource extraction and processing. As industries strive for sustainability, employing gyratory technology stands out as a viable strategy to mitigate environmental impact while maintaining productivity.

Gyratory crushers are essential components in the mining and aggregate industries, known for their ability to efficiently process large quantities of material. One of the most significant advantages they offer is improved maintenance and longevity. By utilizing advanced engineering designs, modern gyratory crushers minimize wear and tear on critical components, thus extending the lifespan of the equipment. These crushers feature enhanced lubrication and cooling systems that help to maintain optimal operating temperatures and reduce the frequency of breakdowns.

Moreover, the design of gyratory crushers supports easier access for inspection and maintenance tasks. This accessibility allows operators to perform routine checks and repairs with minimal downtime, significantly improving operational efficiency. Enhanced diagnostic features also facilitate the early detection of potential issues, allowing for proactive maintenance rather than reactive repairs. As a result, operators can ensure consistent productivity while minimizing unplanned interruptions, leading to overall better performance and reduced total cost of ownership.