-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Maximizing efficiency in crushing operations is crucial for productivity. The Swing Jaw Crusher Plate plays a vital role in this process. Its design and material can significantly impact performance. Understanding the dynamics of this component is essential for operators.

In many cases, the efficiency of the Swing Jaw Crusher Plate is overlooked. Users often focus on the overall machinery instead. However, small adjustments to this plate can lead to noticeable improvements. Attention to its wear patterns offers insights into potential operational changes.

Routine maintenance is another important aspect. Regular inspections of the Swing Jaw Crusher Plate ensure it remains in optimal condition. Ignoring wear can lead to inefficiencies and costly downtime. The fine balance between durability and functionality requires reflection and continuous improvement.

The swing jaw crusher plate plays a crucial role in the efficiency of crushing operations. This component directly impacts the machine's performance by allowing for effective material breakdown. The plate's design promotes maximum surface area contact, facilitating compression and separating the material efficiently. According to industry reports, optimal wear patterns can enhance lifespan and reduce the frequency of replacements.

**Tips:** Regularly inspect the swing jaw plate for wear and tear. This can prevent unexpected breakdowns and ensure consistent performance. Minor adjustments can sometimes yield major improvements.

The functionality of the swing jaw plate is a balance of power and precision. When it wears unevenly, productivity decreases. This is often overlooked in maintenance schedules. With regular evaluations and adjustments, operators can maintain a higher level of efficiency. Data suggests that even a slight misalignment can decrease output by 15% or more.

**Tips:** Consider using advanced monitoring tools to help track plate wear. This can allow for proactive adjustments, saving time in the long run. Remember, small changes can lead to significant results.

This chart illustrates the relationship between various factors affecting the efficiency of swing jaw crusher plate operation. Material type, angle of the swing jaw, feed size, and crusher speed are critical parameters influencing the overall performance of the crusher.

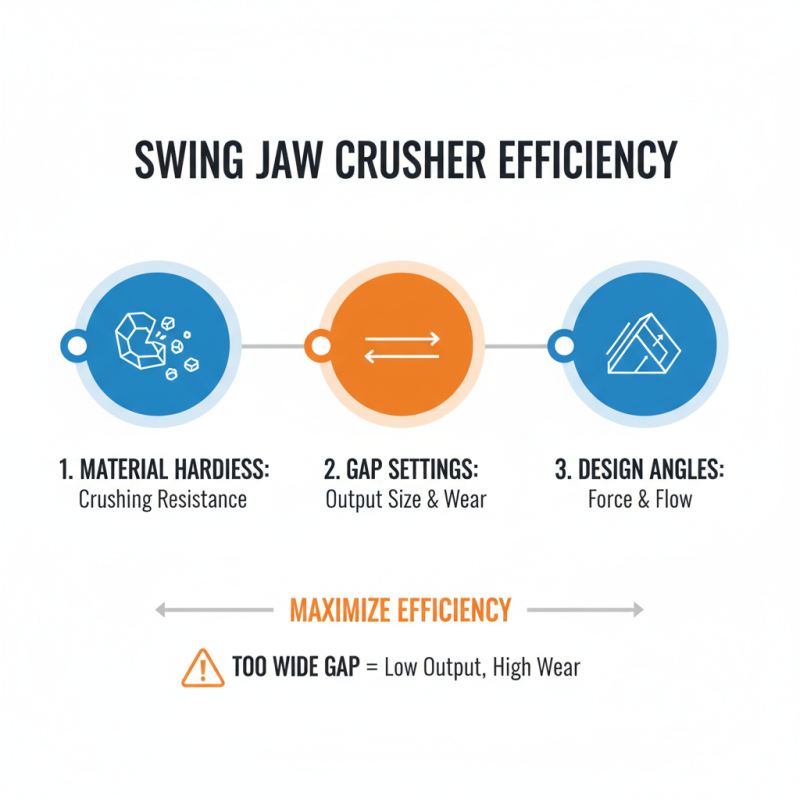

Maximizing efficiency with a swing jaw crusher plate requires understanding its key factors. The efficiency of the swing jaw is crucial to the overall functioning of the crusher. Factors like material hardness, gap settings, and design angles play significant roles. For instance, too wide a gap can lead to increased wear and lower output efficiency.

Tips: Regular maintenance is essential. Check for wear and tear on the swing jaw plate frequently. A worn plate can significantly reduce efficiency. Keep an eye on the angle of the swing jaw. Minor adjustments can lead to noticeable performance changes.

Material choice impacts efficiency as well. Softer materials will crush differently than harder ones. Understanding your material helps optimize settings for maximum output. Experimenting with the input material may reveal surprising results. Finding the right balance may take some time. Yet, it's crucial to avoid jumpy adjustments. Small, gradual changes are ideal for tracking performance improvements.

Maintaining the swing jaw crusher plate is vital for operational efficiency. Regular inspections help identify wear and tear. Check for cracks or unusual wear patterns. It’s essential to conduct these checks even if everything appears normal. A small issue can turn into a big problem later.

Lubrication is another critical aspect. Ensure that the designated grease points receive regular attention. Use the correct type of lubricant and adhere to the recommended intervals. Improper lubrication can lead to increased friction and premature failure. A reminder: over-lubrication can also be harmful.

Keeping the area around the crusher clean is often overlooked. Dust and debris can affect performance. Make it a habit to clear any buildup. Additionally, review operational practices regularly. Does the team adhere to guidelines? Are they aware of common mistakes? Maintaining efficiency is a continual process.

Adjusting operational parameters is crucial for optimizing the performance of a swing jaw crusher plate. One key aspect is the setting of the discharge opening. By modifying this space, you can significantly influence the particle size of the crushed material. A wider opening leads to larger output stones, while a narrow setting produces finer material. However, finding the perfect balance can be tricky. If the opening is too wide, it may result in increased wear on the plates.

Another parameter to consider is the toggle plate tension. This tension controls the gap between the jaws. If it’s too tight, the crushing efficiency might drop. Conversely, if it’s too loose, the crushing forces may fail to break down tougher materials. It requires careful monitoring and adjustments over time. Operators often overlook this aspect, leading to subpar performance and increased operational costs.

Moreover, the speed of the crusher plays a vital role. High speeds can enhance crushing power but might also lead to premature wear. A slower speed might be more effective for hard materials but can reduce throughput. Regularly evaluating the condition of the swing jaw and the corresponding parameters can help maintain optimal efficiency. Remember, there’s always room for improvement and reflection in these operations.

Efficient material selection for swing jaw plates in crushers is crucial. The right materials can enhance performance significantly. Steel alloys often provide a good balance. However, many overlook the importance of weight and scalability. Lighter materials may reduce energy consumption, but could compromise durability.

Tips: Consider stress distribution. A well-designed plate manages forces effectively. Test different materials under real conditions. Observe their wear patterns. This helps in refining your selection process.

Sometimes, the assumptions about strength fail in practical scenarios. What works on paper could lead to underperformance in the field. Testing various thicknesses and shapes is essential. A thicker plate might seem robust, but it could limit movement. Balance is key.

Tips: Regularly review performance data. Understand how different materials age in your specific environment. It's not just about initial cost; longevity matters. Engaging in continuous improvement can yield significant long-term gains.