-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

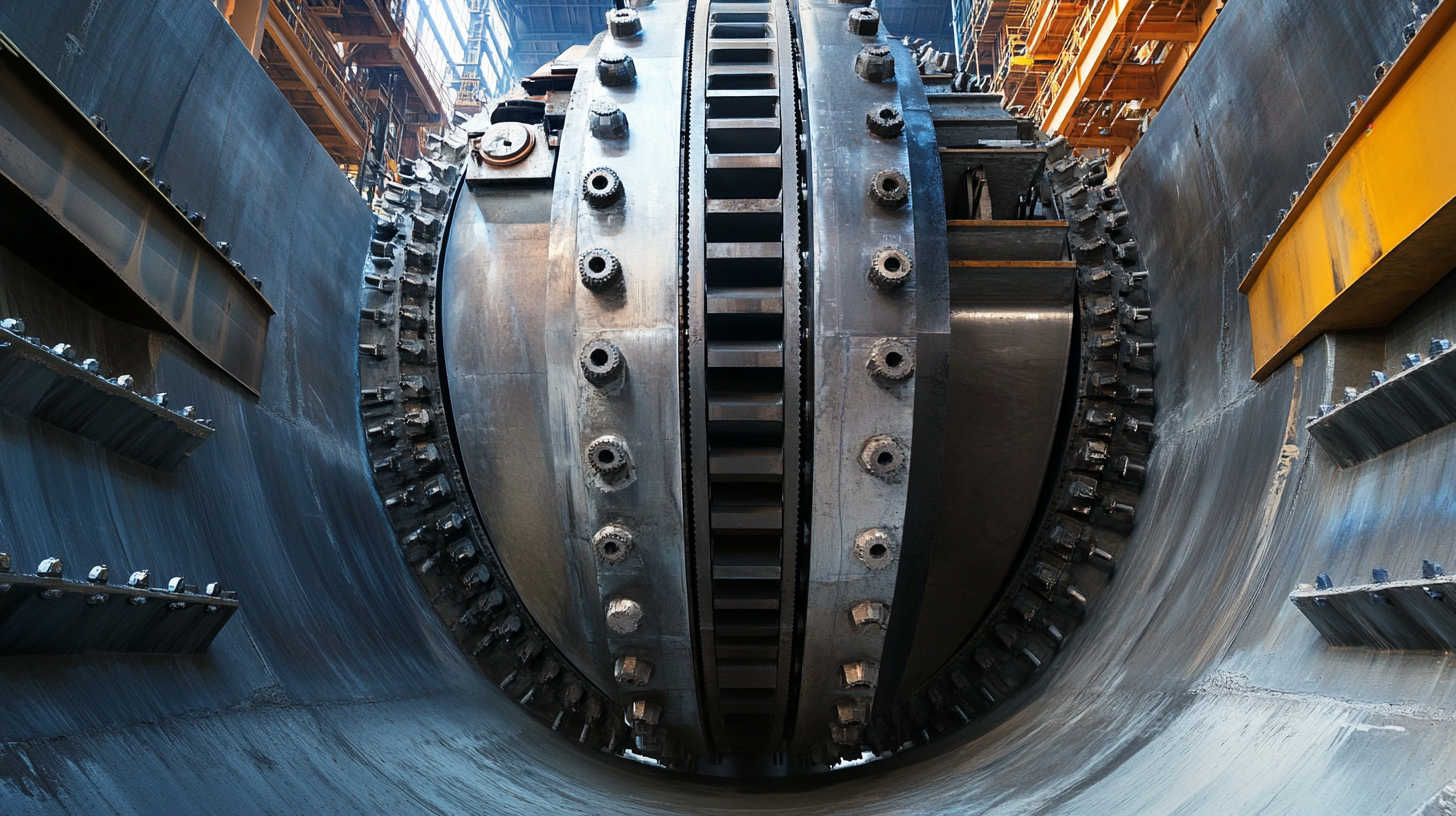

The global demand for high-quality Cone Crusher Parts has seen a significant surge, driven largely by the growing mining and construction industries. According to a recent industry report by Market Research Future, the global cone crusher market is projected to reach USD 1.82 billion by 2027, highlighting the critical role these components play in enhancing operational efficiency and durability of crushing equipment. As a leading export powerhouse, China stands at the forefront of this booming market, leveraging its advanced manufacturing capabilities and robust supply chain to provide unmatched quality products.

Unmatched Quality

Unmatched Quality

When selecting reliable cone crusher parts suppliers, several key traits should be prioritized. First and foremost, the quality of materials used in manufacturing is critical. According to a recent market analysis report by Grand View Research, the global cone crusher market is projected to reach USD 2.9 billion by 2028, emphasizing the importance of durable and high-performance components. Suppliers that utilize high-grade alloys and advanced manufacturing techniques often ensure longer service life and reduced wear rates, which can significantly lower operational costs for users.

Another vital factor is the supplier's ability to provide comprehensive customer support and after-sales services. A study by Research and Markets highlights that companies with robust support systems tend to have higher client retention rates, with some reporting retention as high as 80%. A reliable supplier will not only provide timely deliveries but will also offer technical assistance and parts replacement options, ensuring that clients can maintain optimal equipment performance. By focusing on these key traits, buyers can select suppliers that contribute to their operational efficiency and success in the competitive market.

When exploring suppliers for cone crusher parts, it's crucial to pose the right questions to ensure that you partner with a reliable manufacturer. Start by inquiring about their production capabilities and quality control measures. Understanding the materials used and the processes they implement can provide insights into the durability and performance of the parts they offer. A supplier that maintains rigorous quality standards will likely provide components that withstand the rigors of heavy usage.

Another essential question is about their experience and expertise in the industry. Suppliers with a solid track record in manufacturing cone crusher parts are more likely to understand the specific needs of your application. Ask for references or case studies that demonstrate their ability to deliver high-quality products consistently. Additionally, consider their after-sales support. A committed supplier will not only provide you with quality parts but also assist you with installation, maintenance, and troubleshooting, ensuring optimal performance of your cone crushers over time.

When sourcing cone crusher parts from Chinese suppliers, ensuring quality and compliance is paramount. A comprehensive checklist can serve as a valuable tool in evaluating potential suppliers and their offerings. Start by examining the supplier’s certifications. ISO 9001 or other relevant certifications indicate adherence to international quality management standards, ensuring that the products meet rigorous quality benchmarks.

Next, assess the materials used in the production of the cone crusher parts. High-quality raw materials contribute significantly to the durability and performance of the parts. Requesting material test reports and examining the supplier's manufacturing processes can provide insights into their capability to deliver reliable products. Additionally, consider the supplier's experience and track record in the industry. A well-established supplier with a history of successful partnerships can often reflect reliability and trustworthiness in their offerings.

Finally, do not overlook the importance of after-sales support and warranty policies. A supplier that stands behind their products with solid warranty terms and responsive customer service is a clear indicator of confidence in their quality. By systematically applying this checklist, you can ensure that you are partnering with a reputable supplier capable of delivering unmatched quality in cone crusher parts.

When selecting cone crusher parts vendors, it’s essential to be vigilant about potential red flags that could indicate a less-than-reliable supplier. One of the primary concerns is the consistency of product quality. Ensure that the vendor can provide certifications and proof of quality assurance processes. A supplier that cuts corners may sacrifice durability, impacting the overall performance of your operations.

Another critical factor to consider is the vendor’s customer service and support. An unresponsive or dismissive vendor can lead to significant downtime during crucial operations. Look for suppliers who are willing to engage with you, answer your questions thoroughly, and provide timely assistance. A reliable vendor will prioritize strong communication and support, even after the sale.

Lastly, investigate the vendor's reputation in the industry. Reviews, testimonials, and case studies can shed light on the experiences of other clients. If a vendor has consistently negative feedback or a lack of verifiable success stories, it may be wise to rethink your choice. Opt for vendors with a proven track record of supplying high-quality cone crusher parts and building lasting relationships with their clients.

| Criteria | Details | Importance Level |

|---|---|---|

| Material Quality | Verify the quality of steel and alloys used | High |

| Manufacturing Process | Check for adherence to strict manufacturing standards | Medium |

| Supplier Reputation | Research reviews and ratings from previous customers | High |

| Delivery Times | Assess the vendor’s historical delivery performance | Medium |

| Technology & Equipment | Evaluate modernity and reliability of the equipment used | High |

| Customer Service | Check responsiveness and support availability | Medium |

| Warranty & After-Sales Support | Confirm warranty and support issue resolution policies | High |

| Compliance & Certifications | Check for international quality certifications | High |

Building lasting relationships with export suppliers in China is crucial, especially in the current climate of shifting geopolitical dynamics. As U.S.-China relations become more complicated, it’s essential to establish trust and communication with Chinese suppliers. Engaging with them directly, scheduling regular meetings, and showing genuine interest in their business operations can help forge strong partnerships. Understanding local business customs and practices can also provide insights that strengthen your collaboration.

Tips for building relationships include:

1. **Cultural Sensitivity**: Invest time in understanding the cultural nuances that influence business interactions in China. This respect can pave the way for smoother negotiations and mutual respect.

2. **Transparency**: Be open about your expectations and objectives while encouraging your suppliers to share their capabilities and challenges. This transparency fosters a collaborative environment that can lead to innovative solutions.

3. **Long-term Commitment**: Consider forming strategic alliances that go beyond transactional relationships. This may involve joint ventures or shared investments in technology or processes, which can lead to greater mutual benefits.

By prioritizing these strategies, businesses can effectively navigate the complexities of today's global market while solidifying their presence in the Chinese export arena.

This chart illustrates the export volume of cone crusher parts from China over the last four years, indicating a steady growth in exports as the industry continues to expand and thrive.