-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the world of heavy machinery, the efficiency and reliability of a cone crusher are largely influenced by its components. The Ultimate Guide to Cone Crusher Components Comparison for Optimal Performance aims to provide a comprehensive analysis of these critical parts, ensuring you understand how each component contributes to the overall functionality and effectiveness of the machine.

From the mantle and bowl liner to the eccentric and hydraulic systems, each element plays a vital role in optimizing performance and extending longevity. This guide will delve into the best types of cone crusher components available on the market, comparing their features and benefits to help you make informed decisions that enhance productivity and reduce operational costs.

Whether you're a seasoned industry expert or new to the field, this in-depth resource will equip you with the knowledge needed to elevate your performance and achieve the best results.

When it comes to optimizing the performance of cone crushers, understanding the key components is crucial. The primary elements include the mantle, concave, and the eccentric assembly. According to a report from the Mining Data Analysis Group, approximately 50% of operational downtime in crushing operations is due to wear and tear of these components. The mantle, shaped like a cone, is responsible for crushing the material against the fixed concave. Their interaction not only determines the efficiency of the crushing process but also significantly affects the overall throughput and energy consumption of the system.

In addition to the mantle and concave, the eccentric assembly plays a vital role in facilitating the gyrating motion that is essential for crushing materials. Recent studies highlight that a well-functioning eccentric assembly can enhance crushing efficiency by up to 20%. Moreover, the design and material selection for these components directly influence their lifespan and the cost of maintenance, making the right choice a pivotal point for operational success.

Understanding these components and their roles allows operators to make informed decisions that can lead to improved performance and reduced operational costs.

When comparing cone crusher components, it’s vital to focus on five essential factors: material quality, design configuration, maintenance needs, cost-effectiveness, and compatibility with existing systems. According to a report by Allied Market Research, the global cone crusher market was valued at approximately $1.5 billion in 2020 and is projected to reach $2 billion by 2027, highlighting the importance of selecting the right components for optimal performance.

One key tip is to prioritize material quality. Premium alloy steels and high manganese steel are commonly used in the manufacturing of components, as they provide superior wear resistance and durability. This can significantly reduce downtime and maintenance costs, ultimately enhancing your operational efficiency. Additionally, design configurations, such as the chamber geometry and the type of eccentric throw, can greatly influence the feed size and granulation, impacting production rates.

Consider the maintenance demands of various components. Some designs offer easier access for replacement and repairs, which can save time and resources. Furthermore, when evaluating cost-effectiveness, it’s crucial to balance initial investment against long-term performance results. Selecting components that are compatible with existing systems can also prevent unexpected costs and ensure seamless integration, promoting overall productivity in your operations.

The performance of a cone crusher is significantly influenced by the quality of the materials used in its components. High-quality materials enhance durability and efficiency, directly affecting the crusher's ability to handle various types of materials. For instance, components made from premium steel or advanced alloy materials can withstand higher levels of stress, leading to longer wear life and reduced downtime. This not only ensures consistent production rates but also lowers operational costs over time.

Moreover, the selection of material impacts the crusher’s overall performance in different applications. When processing tougher rocks or abrasive substances, high manganese steel liners offer superior resistance to wear while still maintaining the necessary grip for effective crushing. Conversely, using lower quality materials can result in premature failure, reducing the machine’s lifespan and leading to costly repairs. Therefore, investing in high-quality components is crucial for optimal cone crusher performance and achieving sustainable operations in the long run.

| Component | Material Quality | Impact on Performance | Optimal Material Choice |

|---|---|---|---|

| Mantle | High Manganese Steel | Enhanced wear resistance leading to longer life | Easily formable, better impact strength |

| Concave | Chrome Molybdenum Steel | Improved material toughness and ductility | Excellent for high-impact applications |

| Bowl Liner | Alloy Steel with Manganese | Provides high resistance against abrasion | Maintains form under extreme conditions |

| Eccentric Shaft | Forged Steel | Stronger support, reduces vibration | High tensile strength and durability |

| Hydraulic Cylinder | High-Grade Alloy | Consistent performance under pressure | Ensures reliability and safety during operation |

When operating a cone crusher, understanding and addressing common issues with its components can significantly enhance performance and longevity. One frequent problem is premature wear and tear on the liners, which can be exacerbated by incorrect feed sizes or abrasive materials. To avoid this, ensure that the feed material is consistently within the recommended size and monitor the composition of the materials being processed to limit the presence of highly abrasive elements.

Another common issue involves the hydraulic system, which can develop leaks or malfunctions due to contamination or improper maintenance. Regularly checking fluid levels and maintaining cleanliness in hydraulic components are essential practices to prevent failure. Additionally, implementing a routine maintenance schedule can help detect potential issues before they become significant problems, ensuring that the hydraulic system operates smoothly and efficiently.

Lastly, bearing failures can disrupt productivity and lead to costly repairs. Maintaining proper lubrication and monitoring temperature levels can help in preventing bearing issues. It's important to regularly inspect bearings for signs of wear and replace them periodically based on usage, thereby extending the life of the cone crusher and improving overall operational efficiency.

Optimizing the efficiency and longevity of cone crushers is crucial for maximizing productivity in mining and aggregate operations. According to a report by the Mining Industry Council, effective maintenance practices can enhance a cone crusher's lifespan by 20-30%. Regular inspections and timely replacement of worn components, such as liners and mantles, are vital for maintaining performance. Utilizing high-quality materials can significantly mitigate wear and improve the overall operational efficiency, ensuring that production remains uninterrupted.

In addition to component maintenance, the selection of the right crushing chamber configuration plays a pivotal role in optimizing performance. A study published in the Journal of Materials Processing Technology indicates that adapting the crushing chamber to the specific feed material can increase throughput by up to 25%. Moreover, implementing advanced technologies such as automated closed-side setting adjustments can lead to enhanced control over product sizing and reduced operational costs. Integrating these recommendations not only boosts cone crusher efficiency but also extends their working life significantly, aligning with industry best practices for sustained operations.

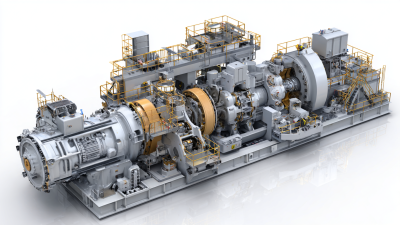

This chart illustrates the impact of different cone crusher components on overall operational efficiency. The Socket Liner and Mantle have the most significant effect, making them crucial for optimization efforts.