-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the world of aggregate processing, the longevity of impact crusher wear parts is crucial. According to John Smith, a noted expert in the industry, "Proper maintenance is key to maximizing the life of impact crusher wear parts." His words remind us that neglecting maintenance often leads to costly breakdowns and reduced efficiency.

Impact crusher wear parts endure significant stress during operation. They face continuous impacts from hard materials. This constant wear can quickly diminish their lifespan if not monitored closely. Regular inspections and timely replacements are essential. A small oversight can result in severe damage, impacting overall production.

Understanding the role of wear parts is vital. They are not merely components; they are the backbone of the crushing process. Each part must be carefully selected based on the material being processed. Even with optimal choices, wear is inevitable. However, embracing a proactive approach can significantly extend their life, ensuring smoother operations.

Impact crushers are essential in many industries. They transform raw materials into usable products. Understanding wear parts is crucial for maximizing their efficiency. Wear parts include hammers, blow bars, and impact plates. These components face significant wear due to constant impact and abrasion during operations.

Data shows that replacing worn wear parts can improve efficiency by up to 30%. However, there is a cost associated with frequent replacements. It is vital to track wear rates. Operators often overlook maintenance schedules. Regular inspections can identify potential issues. This proactive approach can save costs in the long run.

Another study indicates that using high-quality materials for wear parts extends their lifespan. While it may seem costlier upfront, it’s an investment. Yet, many facilities opt for cheaper alternatives. They often face more breakdowns and increased downtime. Balancing cost and quality becomes a challenge. Operators must weigh these factors carefully. Understanding wear parts’ role is essential in optimizing impact crusher performance.

Impact crushers are vital in many industries. However, the wear parts often face significant stress. Understanding the common types of wear parts can help in extending their lifespan.

The most important wear parts are blow bars and impact plates. These components take the brunt of the impact during operation. Blow bars are typically made from high-quality steel. They help in crushing materials effectively, but they wear out quickly. Monitoring their condition regularly is essential. Similarly, impact plates can wear unevenly. This often leads to reduced efficiency, not to mention increased cost for replacements.

Another critical part is the liner. Liners protect the internal parts from damage. They come in various shapes and materials. Over time, they may develop cracks or chips, which require immediate attention. Neglecting to replace worn liners can lead to further damage. Remember, waiting too long leads to unexpected downtime. Regular inspections can prevent this. Recognizing wear patterns can also guide better operational practices. Adjusting operational settings based on wear can yield longer-lasting wear parts.

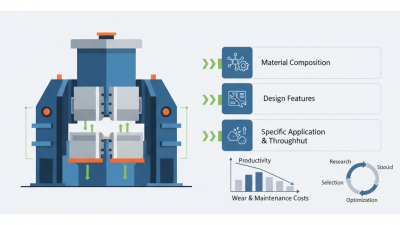

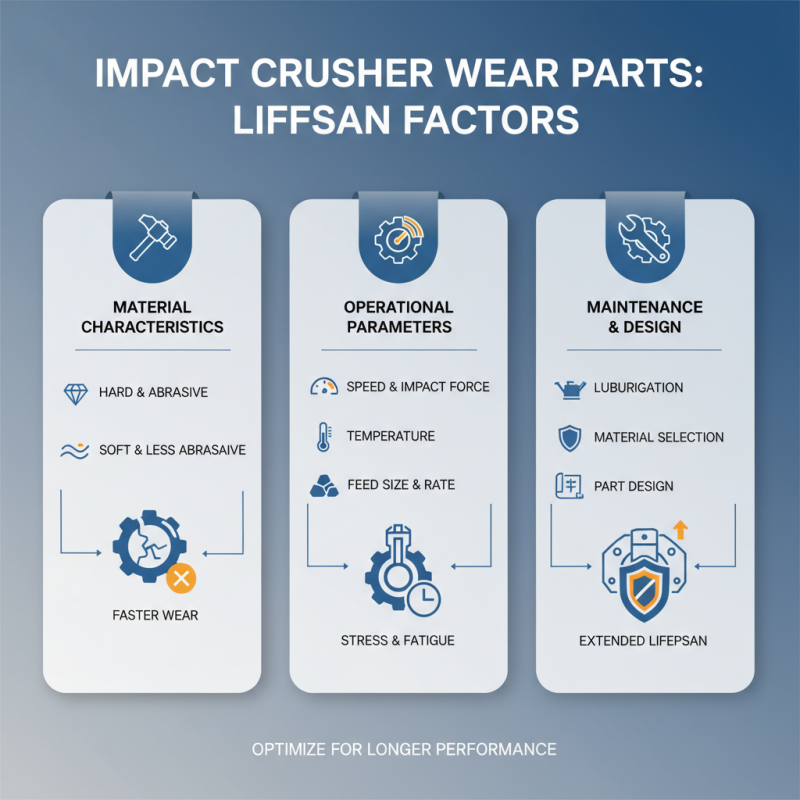

Impact crushers play a crucial role in various industries, but wear parts can face significant challenges. Several factors directly influence their lifespan. Material characteristics are key. Hard, abrasive materials wear down components faster. Soft materials can lead to less wear but may compromise performance.

Operational parameters significantly impact wear. High speeds and aggressive crushing can exacerbate wear, causing premature failure. Conversely, lower speeds may reduce wear but affect output. It's essential to find a balance that suits the specific application. Weather conditions, humidity, and temperature can also affect wear rates.

Tips for extending wear part life include regular inspections. Routine checks can identify issues early. Ensure proper material selection and match it to the equipment. Adjust operational parameters based on material type and desired output. Keeping the working environment clean helps too. Less debris reduces wear and improves efficiency. Regular maintenance isn’t just advisable; it’s necessary.

Proper maintenance is crucial for extending the life of impact crusher wear parts. Regular inspections can help identify wear patterns early. This allows operators to replace parts before they cause major damage. Keeping a close eye on the condition of components reduces unexpected downtime.

Cleaning wear parts regularly is essential. Dust and debris can accumulate, affecting performance. A simple wash can reveal hidden issues. Additionally, using the right lubricants can prevent premature wear. Properly lubricated parts operate more efficiently and last longer.

Operators often overlook the significance of using the correct feed material. Incompatible materials can lead to faster wear. It's vital to ensure the feed is consistent and matches the crusher's specifications. Ignoring this can lead to performance issues and increase repair costs. Investing time in maintenance prevents costly repairs in the long run.

| Maintenance Practice | Frequency | Description | Impact on Wear Parts Life |

|---|---|---|---|

| Regular Inspections | Weekly | Check for wear and damage on parts | Early detection of issues |

| Proper Lubrication | Monthly | Ensure all moving parts have adequate lubrication | Reduced friction and wear |

| Sharp Edges | As needed | Keep crushing edges sharp for optimal performance | Improved crushing efficiency |

| Monitor Operating Conditions | Daily | Check for excessive vibration or abnormal sounds | Prevention of further damage |

| Use of Quality Materials | N/A | Select high-quality materials for wear parts | Better resistance to wear and prolongs life |

Upgrading wear parts is essential for improving the impact crusher's performance and durability. High-quality materials can significantly enhance the lifespan of these components. For example, using tougher alloys can help resist abrasive wear while maintaining impact strength. Regular evaluation of wear patterns also aids in timely replacements. Monitoring and analyzing wear rates can be crucial to keep the equipment running efficiently.

Incorporating improvements to design is another effective strategy. Enhanced geometries of wear parts can lead to better material flow and reduced clogging. This can optimize production rates and reduce downtime. Simple upgrades might seem minor, yet they can significantly impact overall efficiency. It’s important to remember, however, that even the best upgrades require regular maintenance. Neglecting this can lead to premature failure.

Moreover, the cost of premium wear parts may initially seem high. However, when factoring in the potential savings from decreased downtime and maintenance, the investment often pays off. Still, one must constantly reassess if the upgrades are delivering the expected benefits. Staying proactive and informed is key to making the right choices.