-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

The primary gyratory crusher parts are crucial components in the mining and aggregate industries, playing a vital role in material reduction and processing efficiency. According to a report by Market Research Future, the global market for primary gyratory crushers is projected to grow significantly, driven by increasing demand for minerals and metals across various sectors. These crushers are renowned for their superior design and durability, providing operators with enhanced performance and lower operational costs. As the industry evolves towards more sustainable practices, understanding the intricate details of primary gyratory crusher parts is essential for optimizing plant operations. This blog will delve into various examples of these components, showcasing how innovations in their design can lead to improved productivity and reliability in crushing operations.

The primary gyratory crusher parts are crucial components in the mining and aggregate industries, playing a vital role in material reduction and processing efficiency. According to a report by Market Research Future, the global market for primary gyratory crushers is projected to grow significantly, driven by increasing demand for minerals and metals across various sectors. These crushers are renowned for their superior design and durability, providing operators with enhanced performance and lower operational costs. As the industry evolves towards more sustainable practices, understanding the intricate details of primary gyratory crusher parts is essential for optimizing plant operations. This blog will delve into various examples of these components, showcasing how innovations in their design can lead to improved productivity and reliability in crushing operations.

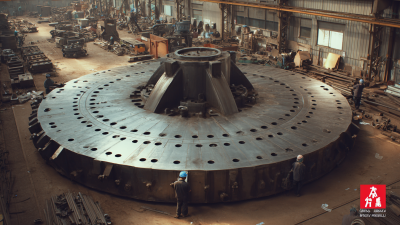

The primary gyratory crusher plays a crucial role in the mining and aggregate industries, serving as the first stage in the crushing process. Understanding the function of each part of the primary gyratory crusher is essential for maximizing operational efficiency. For instance, the mantle, which rotates to crush the material against the concave, must be made from high-quality materials to ensure durability and longevity. A study from Mining Technology shows that the lifespan of the mantle can significantly affect the overall productivity, with optimally designed mantles increasing throughput by up to 20%.

Additionally, the spider assembly, which supports the mantle and absorbs the forces generated during crushing, must be meticulously maintained. Industry reports indicate that improper spider assembly management can lead to increased vibration and, ultimately, premature wear of other components. Furthermore, ensuring that the eccentric shaft operates smoothly is vital for maintaining a consistent output size and separating undesired materials effectively. By focusing on the functionality of each part—such as the spider cap, the head nut, and the drive assembly—operators can fine-tune their equipment for peak performance, resulting in more efficient crushing and reduced operational costs.

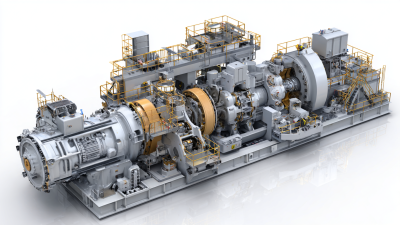

Primary gyratory crushers are crucial for the mining and aggregate industries, designed for crushing large volumes of material efficiently. At the heart of their performance lie several key components that directly influence their efficiency and reliability. The primary component is the crushing chamber, which determines the size and shape of the crushed material. The configuration of the mantle and concave plays a significant role in optimizing the crushing process, ensuring that the maximum amount of material is processed with minimal energy consumption.

Another critical component is the drive assembly, which includes the large motor and gears that power the crusher. The design and quality of these parts are essential for maintaining consistent performance and preventing mechanical failures. Additionally, the hydraulic system, used for adjusting the gap between the mantle and concave, allows for precise control over the material output size, enhancing the versatility of the crusher in various applications. Regular maintenance and timely replacement of these key components are vital for sustaining the operational efficiency of primary gyratory crushers, ultimately leading to improved productivity in material handling.

In the realm of gyratory crushers, the incorporation of innovative materials into their parts is essential for enhancing performance and durability. Modern advancements have introduced materials that withstand extreme wear and tear, ensuring longevity and reliability in demanding environments. For instance, high-grade alloys and composite materials are increasingly being used to manufacture components such as the mantle and bowl liners, resulting in improved resistance to impact and abrasion. This not only reduces the frequency of replacements but also optimizes operational efficiency.

Tips for choosing durable gyratory crusher parts include evaluating the material quality and understanding the specific requirements of your application. Opt for parts designed with advanced metallurgy that can handle the specific challenges of your mining or quarrying operations. Additionally, always consult with suppliers about the latest advancements in materials and technologies that can provide enhanced performance. Investing in high-quality parts can significantly affect throughput and ultimately lead to a more cost-effective operation.

Moreover, regular maintenance and timely upgrades of your equipment, focusing on specific areas where wear is common, can greatly extend the lifespan of your gyratory crusher. Emphasizing on innovation and proactive management of your machinery will foster a more productive and reliable crushing process.

Maintaining primary gyratory crusher components is crucial for ensuring optimal performance and longevity. Regular inspection is essential; worn parts like liners and mantles should be checked for signs of wear and tear, as any deterioration can lead to inefficiencies and potential breakdowns. It’s advisable to establish a routine maintenance schedule that includes not only inspection but also timely replacement of these critical parts before they reach the end of their operational lifespan.

Another important aspect of maintenance is lubrication. Proper lubrication reduces friction between moving parts, minimizes heat buildup, and ultimately leads to longer equipment life. Utilizing high-quality lubricants and adhering strictly to the manufacturer's guidelines for oil change intervals can greatly enhance the performance of gyratory crushers. Additionally, maintaining the hydraulic systems that control the movement of the crusher’s components is vital; ensuring these systems are free from leaks and obstructions is key to operational efficiency. By focusing on these maintenance tips, operators can significantly prolong the life of primary gyratory crusher parts and maintain peak performance in their operations.

When it comes to primary gyratory crushers, understanding the comparative features of various brands is crucial for maximizing operational efficiency. Notable brands such as Metso, FLSmidth, and Thyssenkrupp have established themselves in the market, each offering distinct features that enhance performance. For example, Metso's Superior™ series is known for its robust design and high-capacity throughput, reaching 1,400 to 1,500 tons per hour, while FLSmidth’s Top Service Crusher allows for easy maintenance due to its innovative top service design.

In a recent industry report, it was highlighted that approximately 70% of mining operations see an increase in productivity when switching to modern primary gyratory crushers with advanced automation features. Thyssenkrupp’s Kubria® series stands out with its intelligent automation, which improves wear part management and reduces downtime by incorporating predictive maintenance algorithms.

**Tips:** When selecting a primary gyratory crusher, consider not only the throughput but also features such as ease of maintenance and energy efficiency. Investing in a model with advanced automation can lead to significant cost savings in the long run. It’s also advisable to analyze the brand’s support services and spare parts availability to minimize operational disruptions.

| Part Type | Material | Weight (kg) | Features | Compatibility |

|---|---|---|---|---|

| Concave | Manganese Steel | 450 | High wear resistance | All Gyratory Crushers |

| Mantle | Manganese Steel | 500 | Enhanced crushing capacity | All Gyratory Crushers |

| Hydraulic System | Steel | 1200 | Automatic adjustment | Specific Models |

| Frame | Cast Iron | 2500 | Robust design | All Gyratory Crushers |

| Drive Motor | Electrical | 800 | High efficiency | All Gyratory Crushers |