-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the rapidly evolving mining and construction industries, the demand for high-quality cone crusher parts has surged, driven by the need for increased efficiency and durability in crushing operations. According to a recent report by Research and Markets, the global cone crusher market was valued at approximately $1.1 billion in 2020, with expectations to expand at a compound annual growth rate (CAGR) of 4.2% from 2021 to 2026. This trend underscores the critical role that quality cone crusher parts play in enhancing performance and reducing downtime.

As manufacturers strive to meet stringent industry standards while optimizing their supply chains, sourcing the best cone crusher parts globally has become paramount. By implementing strategic sourcing practices and leveraging industry insights, businesses can significantly bolster their operational effectiveness and maintain a competitive edge in the market.

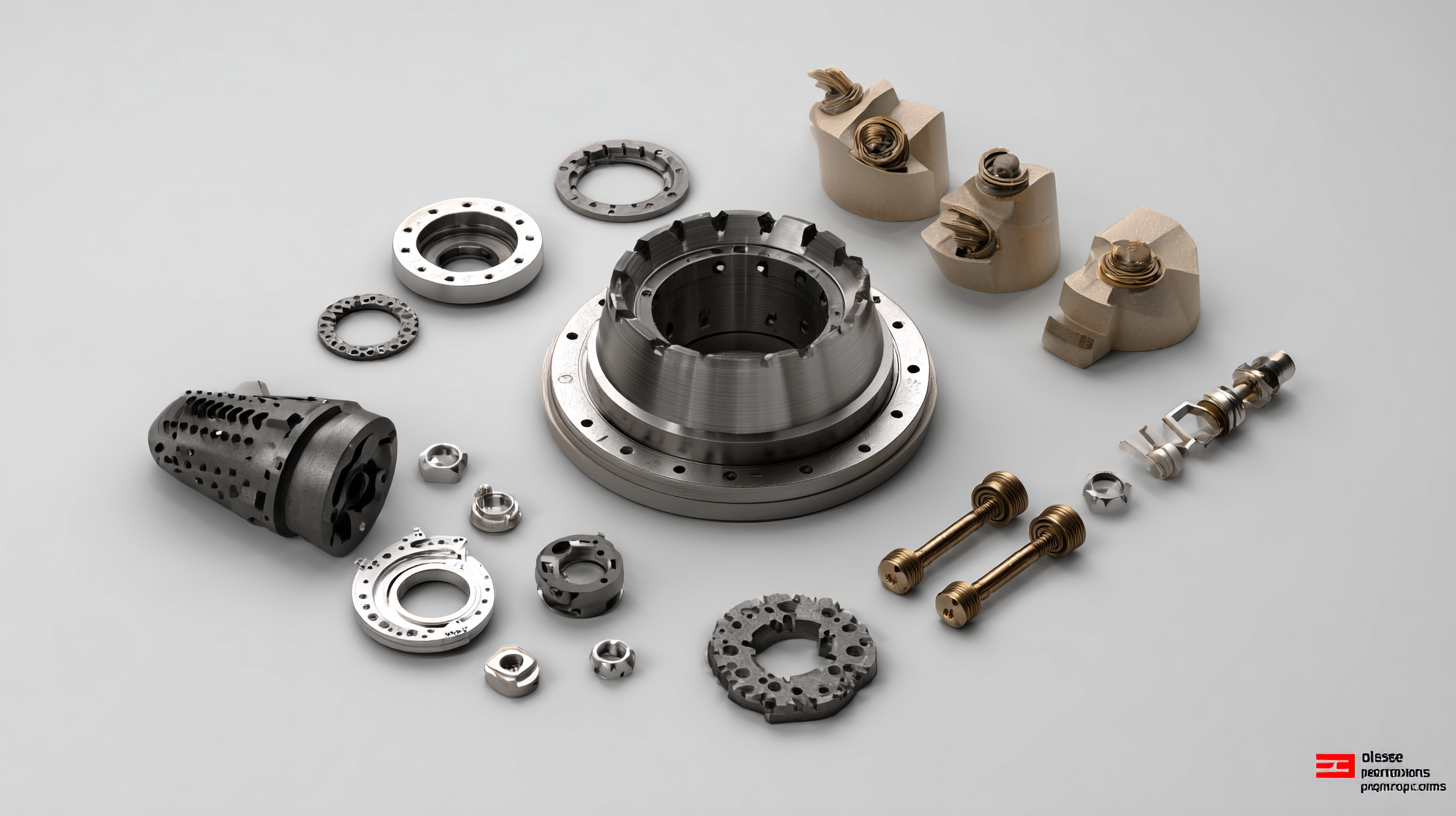

When selecting high-quality cone crusher parts, it is crucial to consider several key factors that can significantly impact the performance and longevity of your equipment. Firstly, material quality plays a pivotal role; parts made from premium grades of steel or high-quality alloys are essential for durability and resistance to wear. It’s advisable to choose manufacturers who adhere to stringent quality control processes and can provide certified materials, ensuring that the parts will withstand rigorous operational demands.

Additionally, compatibility is another critical factor in sourcing cone crusher parts. Ensuring that the parts are compatible with your specific model will optimize efficiency and reduce the risk of premature failure. It's important to collaborate with suppliers who possess in-depth knowledge of different cone crusher models and can provide tailored recommendations. Lastly, the sourcing process should involve a comprehensive evaluation of the supplier's reputation and after-sales support, as reliable service can enhance operational continuity and reduce downtime.

When sourcing cone crusher parts globally, understanding the material composition and durability of components is crucial for ensuring operational efficiency and longevity. According to a report by the Mining Equipment Market Research Group, the choice of materials can significantly influence performance, with high-quality steel alloys being a common recommendation for wear parts due to their superior tensile strength and resistance to abrasion. For instance, manganese steel, which is known for its high impact strength and ductility, is frequently used in crusher liners and mantles, providing a balance between hardness and tensile strength.

Moreover, recent studies conducted by the Journal of Materials Engineering reveal that advancements in metallurgical processes have led to the development of composite materials that enhance the durability of cone crusher parts. These materials often incorporate chromium and molybdenum, which can increase wear resistance and reduce the frequency of replacements. The report highlights that investment in advanced material technology can lead to a reduction in downtime by as much as 20%, ultimately cutting operational costs. By focusing on these factors when sourcing components, companies can significantly improve their crusher performance and reliability in demanding environments.

| Component | Material Composition | Durability Rating | Recommended Hardness | Common Applications |

|---|---|---|---|---|

| Mantle | Manganese Steel | High | HRC 14-22 | Primary Crushing |

| Concave | Manganese Steel | Medium | HRC 18-22 | Secondary Crushing |

| Inner Eccentric Bushing | Bronze Alloy | High | N/A | Rotational Parts |

| Main Shaft | Alloy Steel | Very High | HRC 28-32 | Structural Support |

| Spider Cap | Cast Iron | Medium | N/A | Top Protection |

When sourcing cone crusher parts globally, evaluating potential suppliers is crucial for ensuring reliability and quality assurance. One of the primary criteria to consider is the supplier’s reputation within the industry. Researching reviews, testimonials, and case studies can provide valuable insights into their track record. Additionally, checking for certifications, such as ISO, can indicate a commitment to quality and adherence to international standards, ensuring that the parts meet required specifications.

Another essential factor is the supplier’s ability to provide comprehensive customer support. A reliable supplier should not only offer high-quality parts but also be available for technical assistance and guidance. Assessing their responsiveness and willingness to address queries can further highlight their dedication to customer satisfaction. Furthermore, it is beneficial to inquire about their supply chain processes, including sourcing materials and manufacturing practices, to ensure that they adhere to best practices in sustainability and quality control. By focusing on these criteria, businesses can forge partnerships with suppliers that enhance the performance and longevity of their cone crusher machinery.

This chart displays the evaluation criteria for reliability and quality assurance among global suppliers of cone crusher parts, focusing on aspects like material quality, delivery time, pricing, and customer support.

When sourcing cone crusher parts, striking the right balance between cost and quality is crucial. A thorough cost-benefit analysis helps industry professionals align their sourcing decisions with both operational needs and budget constraints. The recent challenges in various industries, including aircraft maintenance, highlight the importance of reliability in sourcing. Therefore, taking a strategic approach can lead to more sustainable and effective procurement practices.

One key tip for sourcing high-quality cone crusher parts is to establish strong relationships with reputable suppliers. This not only ensures access to superior products but also fosters better understanding and communication regarding pricing and availability. Additionally, consider leveraging technology in your sourcing process; digital platforms can provide insights into market trends and help you compare prices without compromising on quality.

Another vital strategy is to evaluate the total cost of ownership rather than just the initial purchase price. This includes factors such as maintenance, durability, and performance efficiency. Investing in quality parts might lead to lower long-term costs, as these components tend to perform better and last longer, minimizing downtime and the need for frequent replacements.

The global cone crusher parts manufacturing industry is witnessing significant innovation, driven by emerging trends in technology and an increasing demand for high-performance machinery. As the cone crusher market size is projected to grow from USD 2.69 billion in 2024 to USD 4.16 billion by 2032, manufacturers are investing heavily in research and development. This focus on innovation is leading to the introduction of advanced materials and design techniques that enhance the durability and efficiency of cone crusher parts, making them more cost-effective for end-users.

Additionally, the rise of artificial sand usage in construction is reshaping the industry landscape. Increasingly, manufacturers are producing cone crushers that are better suited for processing this material, ensuring that the equipment meets the evolving needs of the construction sector. As global market dynamics change, it is crucial for industry players to stay upfront with the latest trends in material selection and production technologies to maintain a competitive edge amid rising demand and market growth.