-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the realm of mining and aggregate production, the efficiency and longevity of machinery play a pivotal role in operational success. Gyratory crushers, known for their superior crushing capabilities and ability to handle a wide range of materials, are essential components in many processing plants. According to a recent report by Research and Markets, the global demand for gyratory crushers is projected to grow at a CAGR of over 3% from 2021 to 2026, driven by the increasing need for infrastructure development and mineral extraction.

However, the performance of these machines heavily relies on the maintenance of their critical components, specifically Gyratory Crusher Parts. Effective maintenance strategies not only enhance equipment reliability but also significantly reduce operational costs, making it imperative for operators to adopt best practices in upkeep. In this blog, we will outline seven essential tips for optimizing the maintenance of Gyratory Crusher Parts to ensure peak performance and minimal downtime.

Regular inspections of gyratory crushers are crucial for ensuring their longevity and optimal performance. These massive machines operate under extreme conditions and experience significant wear and tear over time. By conducting routine inspections, operators can identify early signs of wear, misalignment, or other potential issues before they lead to more severe problems. This proactive approach not only minimizes downtime but also extends the lifespan of critical components, ultimately leading to cost savings for the operation.

Moreover, regular inspections help maintain the efficiency of gyratory crushers. An improperly maintained crusher can suffer from reduced throughput and increased energy consumption, negatively impacting overall productivity. By adhering to a strict inspection schedule, operators can ensure that all parts are functioning correctly and that any necessary maintenance is carried out promptly. This commitment to regular checks fosters a safer work environment and assures higher output, reflecting the importance of vigilant maintenance practices in managing these complex machines.

Effective lubrication and cooling system maintenance are crucial for optimizing the performance and longevity of gyratory crushers. Proper lubrication ensures that wearing parts operate smoothly, reducing friction and minimizing wear. According to industry data, inadequate lubrication can lead to increased maintenance costs and downtime. Therefore, it's essential to regularly check and maintain lubrication levels, especially under heavy load conditions.

One tip is to utilize high-quality lubricants that are specifically designed for high-temperature and high-pressure applications. Consistent monitoring of lubrication intervals based on the manufacturer's guidelines can significantly extend the life of critical components. Additionally, integrating a reliable cooling system is essential. As seen in the news regarding the growing wind power sector, maintaining optimal fluid levels is vital. A low level can lead to overheating, impacting performance and potentially causing irreversible damage.

For maximum efficiency, ensure that the cooling system operates within the recommended parameters. Regularly inspect coolant levels to avoid overheating issues. Implementing these best practices not only enhances the operational efficiency of gyratory crushers but also contributes to lower overall maintenance costs.

| Tip Number | Maintenance Tip | Frequency | Best Practices |

|---|---|---|---|

| 1 | Regular Lubrication | Daily | Use quality lubricants specified by the manufacturer. |

| 2 | Inspect Cooling System | Weekly | Check for blockages and leaks in the cooling lines. |

| 3 | Monitor Vibration Levels | Monthly | Use vibration sensors to detect abnormal patterns. |

| 4 | Check Wear Parts | Monthly | Inspect liners, mantles for signs of wear and tear. |

| 5 | Clean Dust and Debris | Bi-weekly | Ensure motor and surrounding areas are debris-free. |

| 6 | Hydraulic Fluid Checks | Monthly | Monitor fluid level and quality; replace if necessary. |

| 7 | Overall System Audit | Quarterly | Conduct a comprehensive review of all systems and processes. |

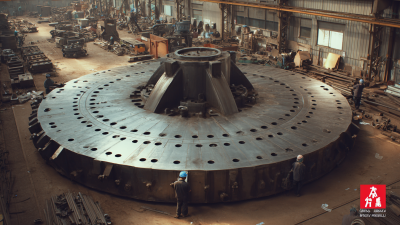

Gyratory crushers play a pivotal role in the mining and aggregate industries, making the maintenance of their components crucial for optimal performance. Key components to monitor include the mantle, concave liners, and spider bushings. According to a report by the International Journal of Mining Science and Technology, routine inspections and timely replacements of these parts can extend their lifespan by up to 30%, reducing downtime and enhancing productivity.

The mantle and concave liners are particularly vital, as they interact closely during the crushing process. A study published in the Journal of Sustainable Mining highlights that maintaining the correct gap between these components can significantly influence the product size and throughput. By regularly monitoring wear patterns, operators can make informed decisions about when to replace these parts, which can lead to improved efficiency and a reduction in operational costs. Additionally, ensuring proper lubrication of the spider bushings minimizes friction, enhancing the overall functioning of the gyratory crusher and further optimizing performance.

When dealing with common issues in gyratory crushers, effective troubleshooting is crucial to minimize downtime and enhance productivity. Advanced diagnostic techniques, such as those based on fast entropy multilevel variational mode decomposition (VMD), have emerged as essential tools in fault diagnosis. This method enables quick and accurate identification of faults, significantly improving maintenance strategies. Research indicates that employing such sophisticated diagnostic methods can reduce unexpected failures by up to 30%, which highlights the importance of integrating modern technology into maintenance practices.

Routine maintenance, coupled with proactive troubleshooting techniques, can further enhance the operational efficiency of gyratory crushers. According to industry reports, maintaining optimal crusher performance can lead to a 10-20% increase in production rates, providing significant economic benefits. Regular inspections and the implementation of predictive maintenance strategies using advanced diagnostic tools can help identify potential issues before they escalate, helping operators maintain a consistent and effective operational flow. Implementing these methodologies not only streamlines the maintenance process but also extends the lifecycle of crucial parts within the gyratory crusher, ultimately leading to reduced operational costs and improved reliability.

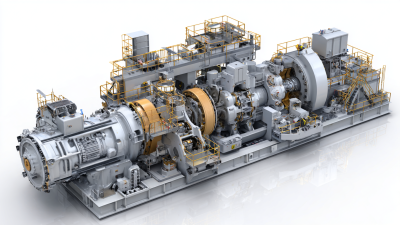

When considering upgrades to gyratory crusher parts, it's essential to assess the operational efficiency and the pressing need for modernization. Recent trends show that mining operators are increasingly turning to digital technologies and service providers to enhance maintenance practices. For instance, proactive upgrades can notably reduce the costs associated with outdated components, significantly improving productivity. Some operations, like those at the Kylylahti site, have successfully integrated new gyratory models, resulting in up to 30% increased throughput compared to previous generations.

The landscape of crusher technology continues to evolve, with the introduction of next-generation models offering enhanced performance and reliability. Upgrading to these advanced systems can mitigate the risks of operational downtime and maintenance challenges. Investing in modern gyratory crushers not only optimizes maintenance efforts but also aligns with the industry's shift towards sustainable and efficient processing. Adapting to such technological advancements ensures that mining operations can maintain a competitive edge in a rapidly changing environment and continue to meet demand effectively.