-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

The efficient operation of a cone crusher is critical for achieving optimal performance in various mining and aggregate industries. As per the latest industry reports, a well-maintained cone crusher can significantly boost production rates by up to 25%, while also reducing operational costs. Key to this efficiency are the essential Cone Crusher Components, which directly influence the machine's reliability and longevity. Components such as the mantle, bowl liner, and hydraulic system play pivotal roles in ensuring consistent product quality and minimizing downtime. Furthermore, studies indicate that regular inspection and timely replacement of these components can lead to a 30% increase in crusher lifespan, thus making it imperative for operators to prioritize their maintenance and performance. Understanding the significance of these components is vital for maximizing the return on investment in crushing operations.

The crushing chamber plays a pivotal role in the operation and efficiency of cone crushers. This chamber is specifically designed to accommodate various sizes and shapes of materials, allowing for optimal crushing. The geometry of the chamber, including its depth and width, directly affects the size reduction process. As materials enter the chamber, they are subjected to intense pressure from the conical head, leading to effective fragmentation and reduced wear on the equipment.

Understanding the dynamics of the crushing chamber is crucial for achieving peak performance. The arrangement of liners within the chamber influences the flow of materials, which is essential for maintaining a consistent feed rate and preventing bottlenecks. Additionally, the chamber's design facilitates the escape of fines, improving the overall efficiency of the crushing process. By optimizing these factors, operators can enhance productivity and prolong the lifespan of the cone crusher, ensuring that it performs at its best under various conditions.

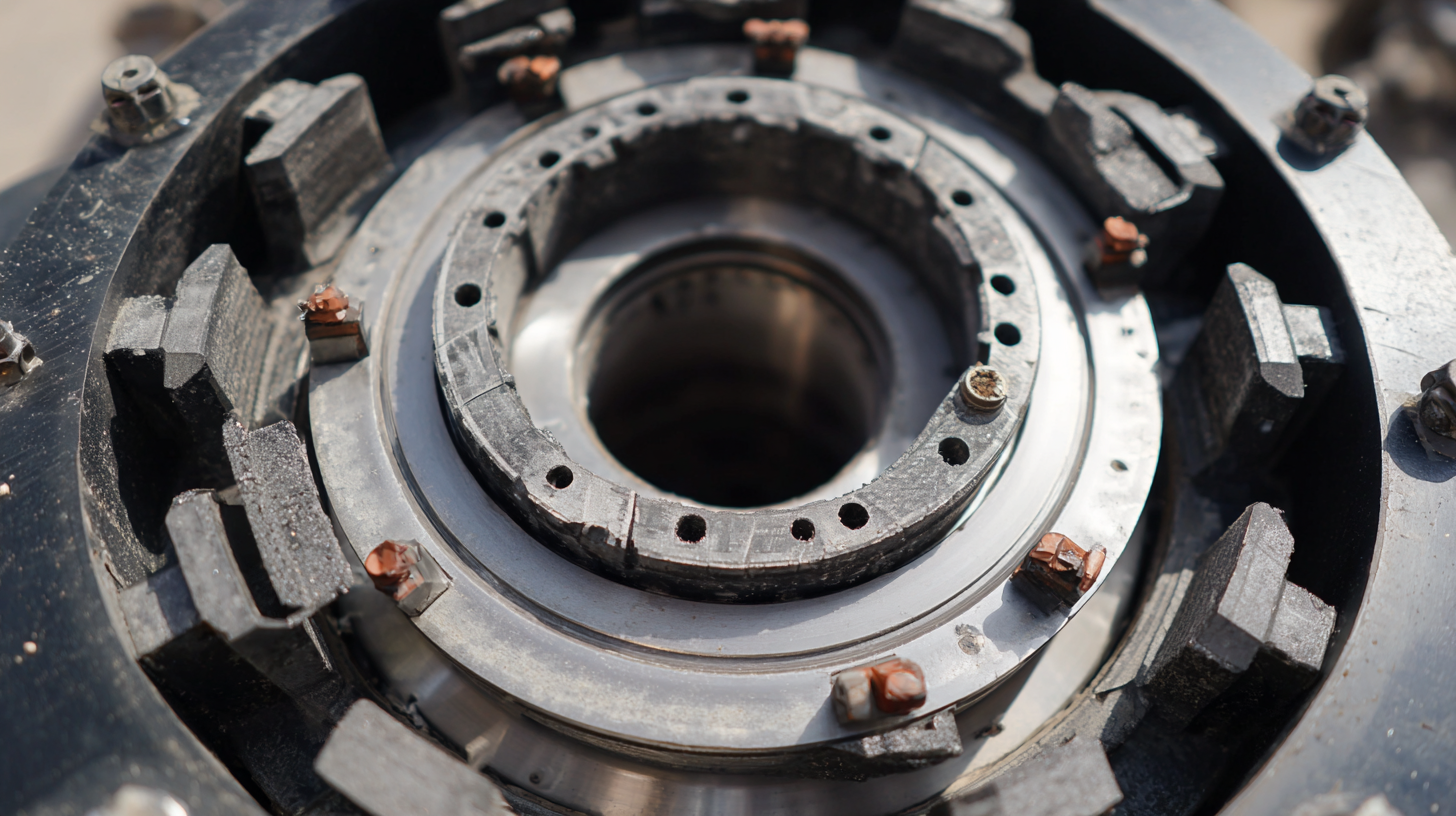

The mantle and concave are two critical components of a cone crusher that play a pivotal role in the efficiency of material crushing. According to industry reports, the geometry and material composition of these components significantly affect the performance of the crusher. For instance, the right manganese steel alloy can improve wear resistance and extend the life of the mantle and concave, ultimately leading to reduced downtime and maintenance costs. Data from a recent study indicates that optimizing these parts can lead to a 10-20% increase in production rates, highlighting their importance in the crushing process.

The mantle and concave are two critical components of a cone crusher that play a pivotal role in the efficiency of material crushing. According to industry reports, the geometry and material composition of these components significantly affect the performance of the crusher. For instance, the right manganese steel alloy can improve wear resistance and extend the life of the mantle and concave, ultimately leading to reduced downtime and maintenance costs. Data from a recent study indicates that optimizing these parts can lead to a 10-20% increase in production rates, highlighting their importance in the crushing process.

Moreover, the interaction between the mantle and concave creates a crushing chamber that is crucial for achieving the desired grain size. Studies suggest that adjustments in the mantle's profile can enhance the crushing force applied to the material, improving the overall efficiency of the operation. As reported by the Journal of Materials Processing Technology, modifications that increase the contact area between the mantle and concave can lead to better fragmentation of materials, ensuring that the end product meets specifications more consistently. As such, investing in high-quality mantle and concave components is essential for any operation seeking to optimize the performance of their cone crushers.

The hydraulic system of a cone crusher is paramount for ensuring optimal performance. Key features include the hydraulic drive, which allows for precise adjustments of the crusher settings, enhancing efficiency and reducing operational costs. Recent innovations in hydraulic design, such as pump-controlled electro-hydraulic systems, have been shown to improve the power flow and energy efficiency in heavy-duty applications. These systems utilize advanced parameters for identification, which can greatly influence the performance metrics of cone crushers.

When considering hydraulic performance, it is essential to monitor the hydraulic fluid's attributes rigorously. Sensor technologies play a crucial role in performance monitoring by providing real-time data that can lead to predictive maintenance strategies. A study highlighted that appropriate sensors can improve system reliability and efficiency up to 20% in industrial manufacturing setups.

**Tips:** Ensure that regular maintenance checks are carried out on the hydraulic system to prevent unexpected failures. Additionally, employing artificial neural networks for optimizing hydraulic parameters could lead to significant improvements in both thermal and hydraulic performance. Leveraging such technology can not only maintain optimal performance but also extend the lifespan of your equipment.

The lubrication system of a cone crusher plays a crucial role in maintaining optimal performance and prolonging the equipment's lifespan. Effective lubrication minimizes friction between moving parts, which can lead to overheating and premature wear. Recent advancements in lubrication technology have been designed to improve efficiency, as evidenced by the integration of automated systems in modern crushers. For instance, automated lubrication systems ensure that bearings are adequately lubricated even during heavy operation, which enhances reliability and reduces downtime.

According to industry reports, a well-maintained lubrication system can improve a cone crusher’s operational efficiency by up to 30%, significantly reducing energy consumption and operating costs. In the context of newer models, such as those equipped with diesel-electric drives, enhanced lubrication systems offer even greater benefits, allowing for higher output and better performance under demanding conditions. Maintenance practices, including regular checks of air breathers and fluid levels, are essential to keep these systems functioning optimally, thereby supporting the overall productivity of crushing operations in quarries.

| Component | Function | Impact on Performance | Recommended Lubrication Type | Maintenance Frequency |

|---|---|---|---|---|

| Mantle | Crushes material | Directly affects throughput | High-Viscosity Grease | Every 250 hours |

| Concave | Forms a crushing chamber | Maximizes product size | ML-EP Grease | Every 200 hours |

| Hydraulic Cylinder | Adjusts the gap | Affects size and shape of output | Biodegradable Oil | Every 500 hours |

| Countershaft | Transmits power | Influences speed and force | SAE 30 Oil | Every 300 hours |

| Drive Motor | Provides necessary power | Crucial for efficiency | Electric Motor Oil | Every 1000 hours |

| Frame | Supports all components | Stability and durability | N/A | Annual inspection |

| Lubrication System | Distributes oil and grease | Enhances longevity | Lithium-based Grease | Weekly check |

| Dust Seal | Prevents contaminants | Protects internal parts | N/A | Every 6 months |

| Adjusting Ring | Holds the concave | Enables gap adjustments | EP Grease | Every 200 hours |

| Bearing Components | Supports rotating parts | Minimizes friction | High-Temperature Grease | Monthly inspection |

The drive system of a cone crusher is critical to ensure reliable operation and optimal performance. Key components of this system include the electric motor, which provides the necessary power to drive the crusher, and the gearbox, which adjusts the speed and torque to enhance crushing efficiency. A well-maintained drive belt is also essential as it transfers the motor’s power to the crusher while minimizing energy loss.

Moreover, a properly aligned drive system significantly reduces wear and tear on machinery, extending the lifespan of the cone crusher. The hydraulic system, responsible for adjusting the crusher's settings and maintaining pressure, plays a vital role in both performance and safety. Regular inspection and maintenance of these components are crucial; any failure in the drive system could lead to costly downtime and reduced productivity. Ensuring these essential components are in excellent condition is vital for achieving the highest levels of operational reliability and efficiency in cone crushing applications.