-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

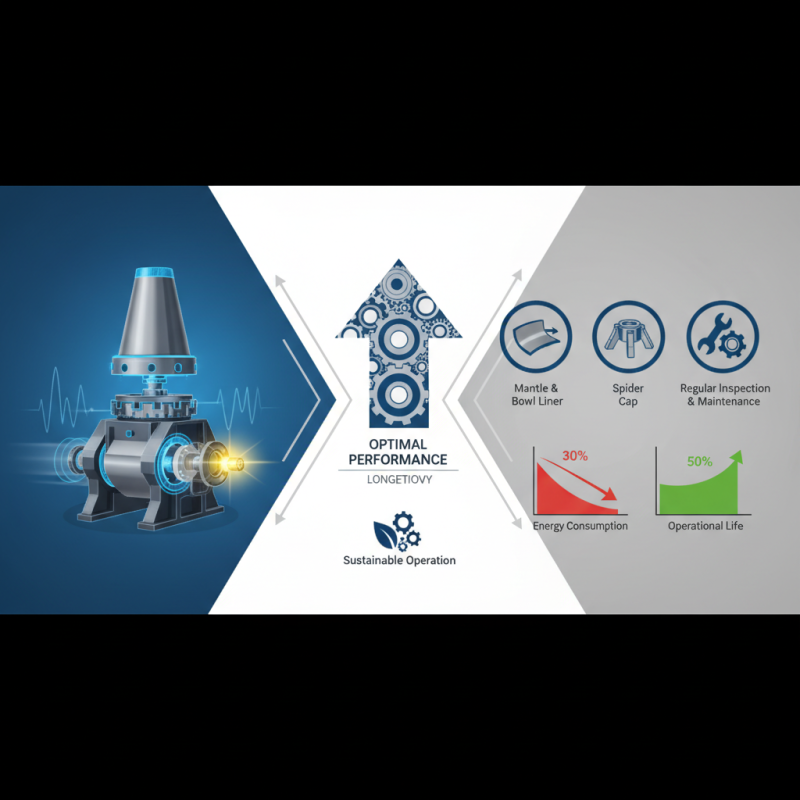

The performance and longevity of cone crushers are paramount in the mining and construction industries, where these machines play a crucial role in crushing a variety of materials. According to a report by the International Journal of Industrial Engineering, improper maintenance and selection of cone crusher components can lead to significant operational inefficiencies, up to 30% higher energy consumption, and increased downtime. Ensuring that the cone crusher components are regularly inspected and well-maintained is essential for achieving optimal performance.

Cone Crusher Components, such as the mantle, bowl liner, and spider cap, are critical in determining the efficiency and longevity of the equipment. A study published by the Journal of Mining Science highlights that timely replacement of these components can extend the operational life of a cone crusher by up to 50%. Moreover, optimizing the design and material of these components not only enhances their durability but also reduces the overall cost of ownership. By focusing on these key elements, operators can maximize productivity while minimizing maintenance costs, contributing to a more sustainable operation in the long term.

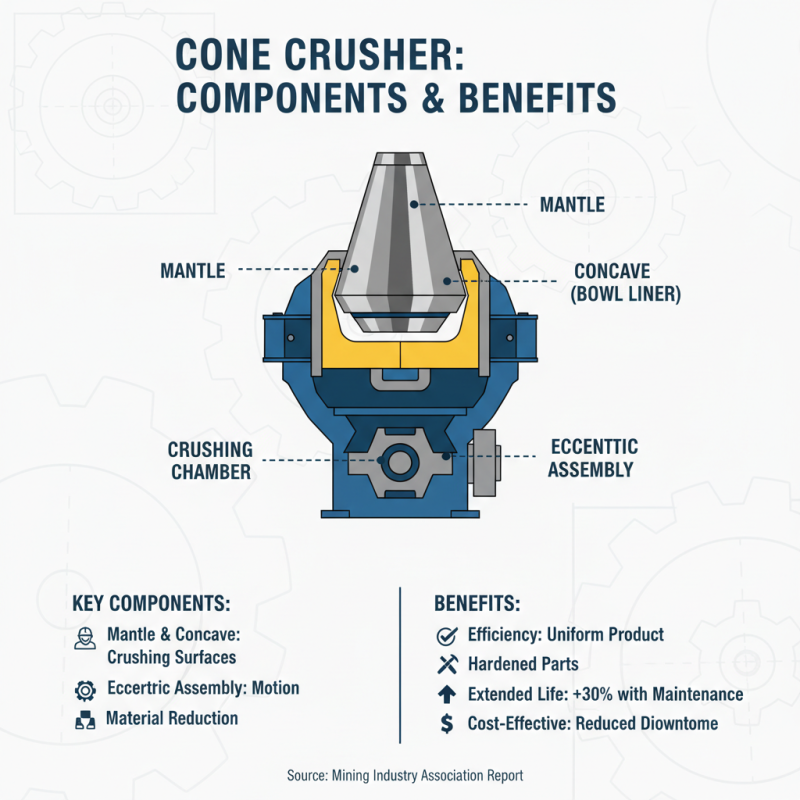

A cone crusher is a vital component in the mining and aggregate industries, renowned for its efficiency in crushing materials into usable sizes. Understanding the basic components of a cone crusher is essential for maximizing its performance and ensuring its longevity. The primary components include the crushing chamber, mantle, concave, and the eccentric assembly, each playing a crucial role in the crushing process. According to a report by the Mining Industry Association, maintaining these parts can enhance operational life by up to 30%.

To achieve optimal performance, it is essential to keep the crushing chamber clean and free of unnecessary material buildup. Regular inspection of the mantle and concave for wear is critical, as these parts directly impact the material output. Additionally, the use of proper lubrication techniques can prevent overheating and reduce wear on the eccentric assembly.

Tips for prolonging the life of cone crusher components include establishing a routine maintenance schedule and training operators in best practices. Investing in high-quality wear parts and actively monitoring operational parameters can greatly minimize downtime and enhance productivity. A well-maintained cone crusher not only improves operational efficiency but also significantly reduces the total cost of ownership, as highlighted in industry benchmarks from the Aggregate Producers Association.

When considering an efficient cone crusher design, certain key features stand out that contribute to optimal performance and longevity. One of the most important aspects is the robust construction of the machine. A well-designed cone crusher is made from high-quality materials that can withstand extreme conditions and heavy usage. This durability is essential for ensuring consistent operation over time, especially in demanding environments.

Additionally, the geometry of the crushing chamber plays a crucial role in the efficiency of a cone crusher. The angle of the mantle and concave, along with the feed and discharge openings, must be optimized to maximize throughput and minimize energy consumption. Properly designed crushing chambers facilitate the effective breaking of materials while ensuring a uniform product size.

**Tips** for enhancing the performance of your cone crusher include regularly inspecting and maintaining key components such as the liners and bearings. Ensuring that these parts are in good condition can prevent costly downtime and extend the lifespan of the machine. Moreover, adjusting the feed rate to match the crusher’s capacity can help avoid unnecessary stress on the equipment, leading to improved efficiency and lower operational costs. Keeping these features in mind will help you achieve an effective and lasting design for your cone crusher.

This chart illustrates the key performance metrics of an efficient cone crusher design based on various operational parameters such as throughput, efficiency, and wear rate. Optimizing these factors is crucial for the longevity and effectiveness of cone crushers.

Maintaining a cone crusher is crucial for ensuring optimal performance and longevity. Regular maintenance practices can significantly extend the lifespan of these machines, which are essential in mining and aggregate production. Research shows that approximately 50% of cone crusher failures can be traced back to improper maintenance. Therefore, implementing a structured maintenance schedule is vital. This includes routine inspections of key components such as the mantle, concave liners, and the hydraulic system. According to a recent industry report, an effective maintenance program can enhance the machine's life expectancy by up to 30%, translating to substantial cost savings over time.

Another critical aspect of maintaining cone crushers is monitoring wear and tear. Operators should regularly check for signs of wear on the liners and other components, as material degradation can lead to decreased efficiency and increased operational costs. Data suggests that replacing worn parts promptly can maintain the crusher's operational efficiency at over 90%. Additionally, keeping the hydraulic system free from contamination plays a vital role; reports indicate that up to 80% of hydraulic failures are due to contamination and lack of proper fluids. Thus, adopting best practices for maintenance not only ensures the reliability of the equipment but also maximizes production output and minimizes unexpected downtimes.

| Component | Description | Maintenance Tip | Expected Lifespan |

|---|---|---|---|

| Cone Head | The main component that crushes the material from above. | Regularly inspect for wear and replace when necessary. | 1-3 years depending on usage. |

| Mantle | The inner surface that interacts with the cone head. | Monitor thickness and replace to avoid damage to components. | 1-3 years. |

| Hydraulic System | Controls the cone's position and crushing force. | Check fluid levels regularly and inspect for leaks. | 5+ years with proper maintenance. |

| Feed Hopper | The entry point for materials into the crusher. | Keep clear of obstructions and check for wear. | 3-5 years. |

| Dust Seal | Prevents dust and debris from entering the internal parts. | Inspect regularly and replace if damaged. | 1-2 years. |

When operating a cone crusher, it's essential to keep an eye out for common issues that may arise and impact performance. One such issue is the buildup of materials in the crushing chamber, which can lead to blockages and reduced efficiency. Regular inspections and maintenance of the feed hopper and cone liner are crucial in preventing this problem. Operators should also be alert for unusual noises, which may indicate wear on components or misalignment within the machine.

To enhance the longevity of a cone crusher, here are some practical tips: First, ensure that the crusher is regularly lubricated according to manufacturer specifications, as inadequate lubrication can lead to excessive wear and overheating. Additionally, monitoring the discharge size is vital; any variations can signify problems with the crushing process or the material being fed into the machine. Lastly, implementing a washout routine to remove debris and prevent contamination can significantly improve performance and reduce the likelihood of mechanical failures.

By being proactive in troubleshooting and maintenance, crusher operators can optimize their equipment's performance, ensuring that it operates smoothly and efficiently for years to come.

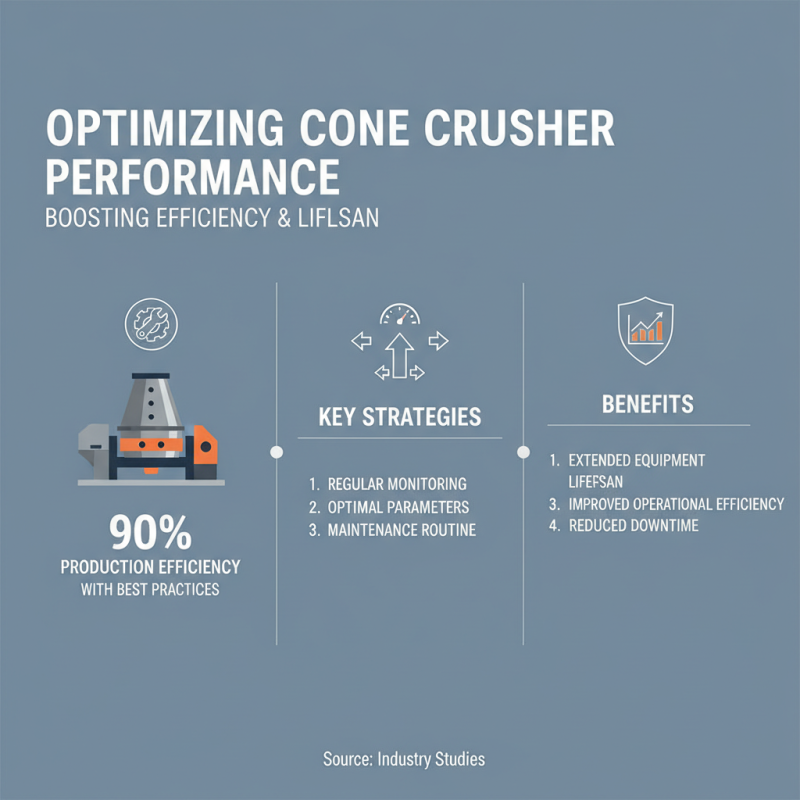

When it comes to optimizing cone crusher performance, implementing best practices can significantly extend equipment lifespan and improve operational efficiency. A well-maintained cone crusher can achieve a production efficiency of up to 90%, as suggested by various industry studies. Regular monitoring of operational parameters, such as power draw and cone angle, is essential to ensure that the equipment is functioning within its optimal range.

One of the key tips for maintaining peak performance involves regular lubrication. According to industry reports, proper lubrication not only reduces friction but also dissipates heat, contributing to longer service intervals. Operators should check oil levels frequently, ensuring that the lubrication system is functioning correctly to avoid unnecessary wear on critical components.

Another crucial aspect is the implementation of a consistent feeding strategy. Studies indicate that a stable feed rate can enhance productivity by as much as 25%. To achieve this, it is advisable to monitor the feed material's size and moisture content, ensuring it meets the crusher's specific requirements. In addition, utilizing a qualified operator who understands the importance of consistent feeding can prevent overload conditions, which are detrimental to both performance and machine longevity.