-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

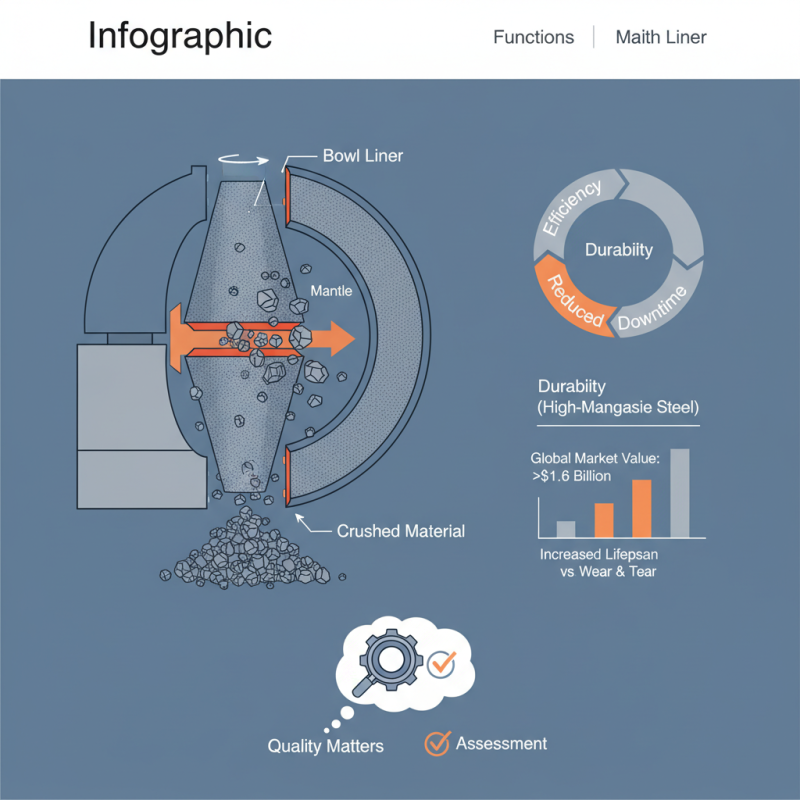

The Cone Crusher Bowl Liner is a critical component in the crushing process. It plays a vital role in the overall efficiency and productivity of the machine. In the mining and aggregate industry, the demand for cone crushers continues to rise. According to a recent report, the global cone crusher market was valued at over $1.6 billion in 2022, highlighting its importance.

The bowl liner's primary function is to create a gap with the mantle, allowing materials to be crushed effectively. With proper operation, a well-maintained Cone Crusher Bowl Liner can significantly reduce downtime. However, wear and tear can lead to performance issues. Many operators overlook this aspect, which may lead to inefficient crushing and unexpected costs.

Quality matters in the selection of bowl liners. Materials, like high-manganese steel, enhance durability and performance. Yet, not all manufacturers provide the same quality. Operators must carefully assess their options, as a poor choice can result in faster degradation. This highlights the need for ongoing evaluation of existing liners to maximize the lifespan and efficiency of the cone crushing process.

A cone crusher bowl liner is a critical component in the crushing process. It sits on top of the cone and helps contain the material that is being crushed. As the cone moves, the bowl liner interacts with it. This crushing action reduces the size of the rock or ore efficiently. The material is fed into the top of the crusher and is pushed down, passing through the narrow space between the bowl liner and the cone.

Maintaining the bowl liner is essential for optimal performance. Regular checks on wear and tear can help prevent unexpected breakdowns. If the liner wears too much, it could lead to inefficient crushing and increased costs. Replacing the bowl liner is part of routine maintenance, but it requires careful attention. Ensure the replacement fits well with the cone’s profile.

Tip: Always keep an eye on the liner’s condition. Small cracks can lead to bigger issues.

The operation of the bowl liner can vary based on factors such as material type and size. Different materials may wear the liner unevenly. Operators need to monitor performance frequently. Feedback can help you identify potential problems early on. Properly training staff can reduce errors in this area. Be aware that variability in performance might occur.

The cone crusher bowl liner is a vital component in the crushing process. It's crucial for directing the rocks onto the crushing chamber. This part is typically made from high-strength materials, such as manganese steel. It needs to withstand immense pressure and wear. However, improper selection can lead to rapid degradation. That's a point to consider.

The bowl liner has a complex shape, fitting snugly within the cone. Its design affects the overall efficiency of the crushing operation. A worn-out liner might lead to uneven crushing and increased energy consumption. Regular inspections are essential. Understanding the wear patterns helps in planning replacements wisely. Ignoring this can result in larger operational costs.

Maintenance of the bowl liner is often overlooked. Many operators underestimate the impact of a well-maintained liner. Small cracks can lead to bigger issues down the line. Replacing a bowl liner doesn’t just impact effectiveness; it can halt production if not planned correctly. This insight could save time and money in the long run. A proactive approach can enhance performance and reduce unexpected downtime.

The bowl liner plays a crucial role in the cone crusher's performance. It is one of the key components that ensures effective crushing. Positioned in the crushing chamber, the bowl liner contacts the material being processed. This contact generates the necessary force to break down the material into smaller pieces.

In crushing operations, the bowl liner serves multiple functions. First, it guides the material as it moves through the machine. This helps to increase efficiency and maximize output. Second, it helps reduce wear on the crusher's internal components. A worn bowl liner can lead to decreased performance and increased maintenance costs. Regularly inspecting and replacing the bowl liner is vital.

Tips: Always monitor the bowl liner for signs of wear. A worn liner can affect the quality of crushed material. Also, consider scheduling regular maintenance checks. This helps extend the life of your equipment and ensures reliable operation. If the performance drops, it may be time to reassess the liner's condition. Regular updates to your maintenance routine can lead to better outcomes.

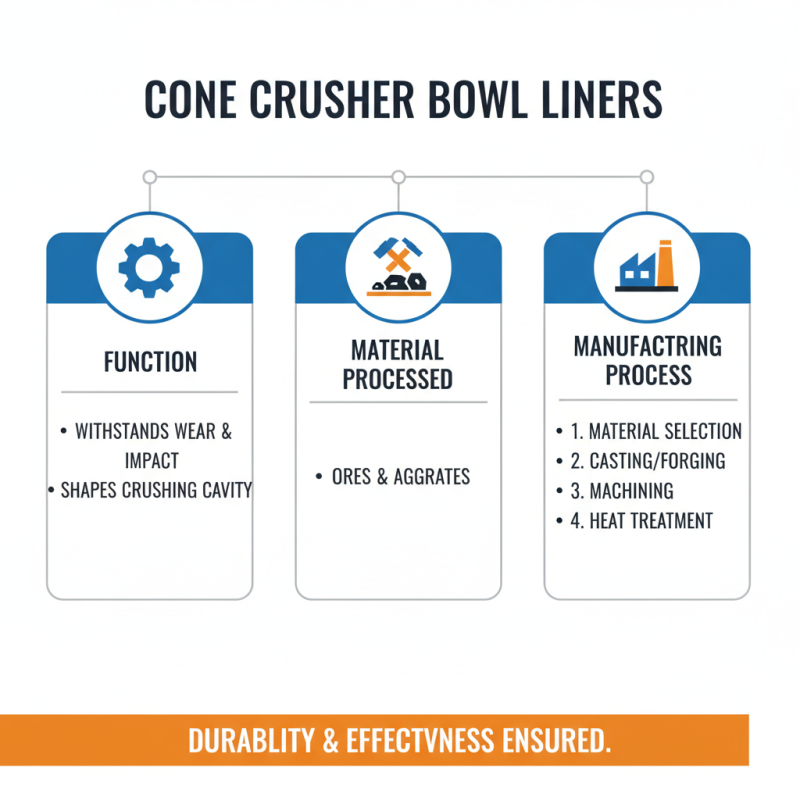

Cone crusher bowl liners play a crucial role in the functionality of cone crushers. These liners are designed to withstand intense wear and impact. They shape the space where crushed material is processed. The manufacturing process of these liners involves several stages, ensuring their durability and effectiveness.

Initially, raw materials such as high-grade steel are sourced. The steel is then melted at high temperatures, creating a molten form. This molten steel is poured into molds to create the bowl liners' shape. After cooling, the liners undergo extensive heat treatment. This step is vital for enhancing their hardness, ensuring they last longer in demanding conditions.

Once treated, the liners are subjected to rigorous quality checks. Each liner is inspected for flaws and defects. Any imperfections can lead to failures in the field. Workers focus on achieving the correct dimensions and surface finishes. This attention to detail is essential, yet it is a challenge in manufacturing. Different batches may show variances that require adjustments. It's a reminder of the complexities involved in creating components that can handle significant wear over time.

Maintaining a cone crusher bowl liner is vital for optimal performance. Over time, wear and tear occur due to constant friction and pressure. Inspecting the bowl liner regularly can prevent unexpected breakdowns. Look for visible cracks or unusual wear patterns. These early signs are crucial for addressing issues proactively.

When replacement is necessary, ensure it is done meticulously. The process involves removing the old liner and installing a new one. This requires precision to avoid misalignment. A misaligned bowl liner can lead to uneven crushing and increased wear. Proper torque specifications are essential during installation.

Neglecting maintenance can result in significant downtime. That translates to lost revenue for operations. It's easy to overlook the small details, but they can have a big impact. Developing a routine inspection schedule is a practical solution. Emphasizing these practices can enhance longevity and efficiency. Incorporating lessons from past mistakes can lead to better decision-making in future maintenance tasks.

| Dimension | Specification | Material Used | Wear Life (Hours) | Replacement Frequency |

|---|---|---|---|---|

| Standard | 22 inches | Manganese Steel | 1000 | Every 1-2 months |

| Medium | 36 inches | Chrome Steel | 1200 | Every 2-3 months |

| Large | 52 inches | High-Quality Manganese | 1500 | Every 4-6 months |