-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Choosing the right cone crusher is crucial for the success of any construction or mining project. With a variety of models and configurations available, understanding the specific requirements of your project is essential in ensuring optimal performance and efficiency. Cone crushers are widely used due to their versatility in crushing and their ability to handle various materials, making them a favored choice for many industries.

When selecting a cone crusher, factors such as the material type, desired output size, and production capacity must be carefully considered. Each project has unique demands, and selecting the right machine can significantly impact operational costs and productivity levels. This guide provides insights into the critical aspects to evaluate when choosing a cone crusher, helping you make an informed decision that aligns with your project needs. By focusing on performance metrics and machine specifications, you can ensure that the cone crusher you choose will deliver the results you require, ultimately contributing to the efficiency and success of your project.

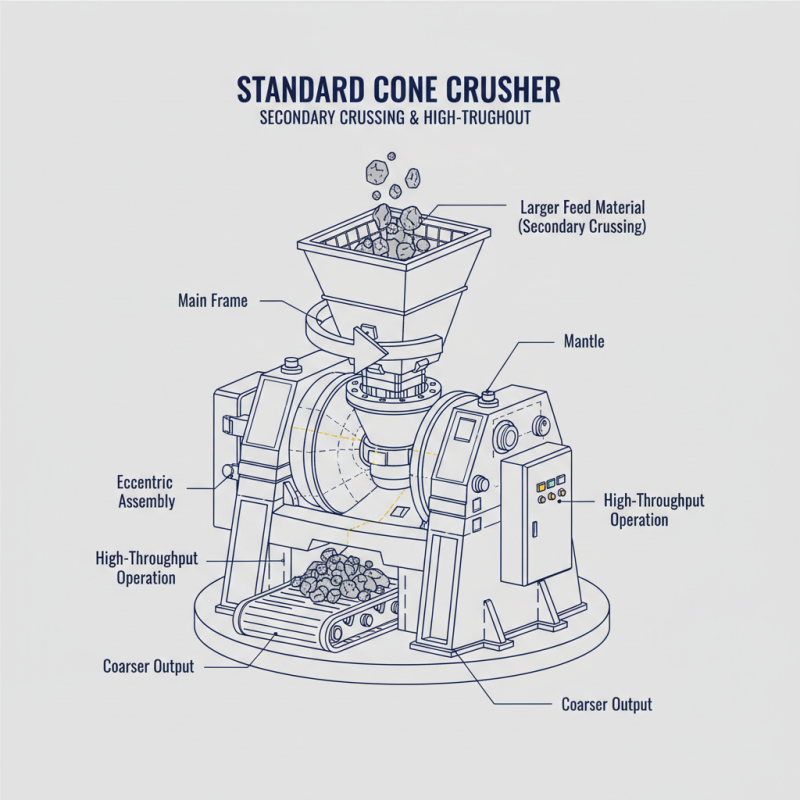

When selecting a cone crusher for your project needs, it's essential to understand the various types available in the market. The most common types include standard, medium, and short-head cone crushers, each designed for specific applications. Standard cone crushers are primarily used for secondary crushing and can accept larger feed sizes, making them suitable for high-throughput operations. They provide a coarser output, which can be beneficial in certain aggregate production processes.

Medium and short-head cone crushers, on the other hand, are ideal for producing finer materials. The short-head design allows for a smaller output size, which is valuable in applications requiring more precise material gradation. These crushers are often used in tertiary and quaternary stages of crushing, where the size reduction is crucial for meeting strict specifications. Understanding the differences in these types largely depends on your project's material requirements, desired output size, and overall processing goals, making it vital to assess your specific needs before making a decision.

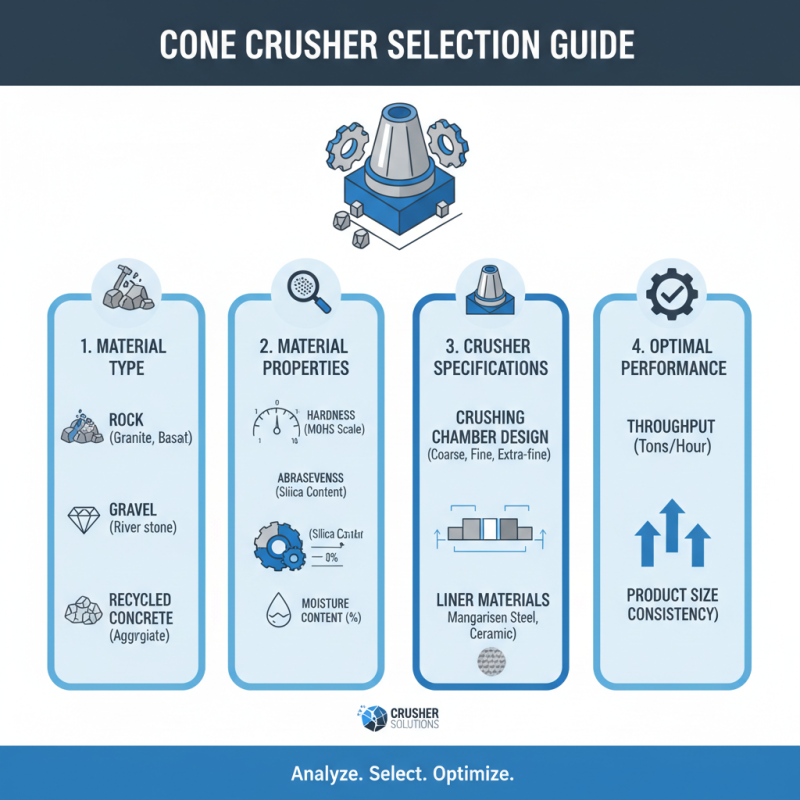

Choosing the right cone crusher is crucial for maximizing efficiency in your project. One of the key factors to consider is the material type you will be processing. Different cone crushers have varying capabilities in handling materials like granite, limestone, or sandstones. Understanding the characteristics of the materials – including hardness, abrasiveness, and moisture content – will help determine the most suitable crusher for your specific needs. Analyzing the feed size and desired output size is also essential, as it affects the crusher's settings and overall performance.

Another important factor is the required production capacity. Depending on the scale of your project, you need to select a cone crusher that can handle the volume of material you plan to process. This involves evaluating the tons per hour (TPH) the crusher can produce under optimal conditions and ensuring it aligns with your operational goals. Additionally, consider the cost of ownership, including initial investment, maintenance, and potential wear and tear. Selecting a cone crusher that balances performance with long-term operational costs will ultimately lead to a more sustainable and profitable project.

| Factor | Description | Consideration |

|---|---|---|

| Crushing Capacity | The maximum amount of material that can be processed in an hour. | Choose based on your project's required throughput. |

| Material Type | The composition and hardness of the material being crushed. | Select a crusher designed for the specific material properties. |

| Size of Output | The desired size of the crushed material. | Ensure the crusher can produce the required final size. |

| Energy Efficiency | The amount of power required to operate the crusher. | Consider operating costs and environmental impact. |

| Maintenance Requirements | The regular upkeep needed to keep the crusher operational. | Look for designs that minimize downtime and maintenance costs. |

| Mobility | The ability to move the crusher between locations easily. | Consider fixed versus portable models based on site needs. |

| Cost | The initial purchase price and long-term operating costs. | Balance budget constraints with necessary features. |

When selecting the right cone crusher for your project, it is crucial to analyze the specific application requirements. Understanding the materials you'll be processing is the first step. Different cone crushers are designed to handle varying types and sizes of materials, such as rock, gravel, or recycled concrete. Assessing the hardness, abrasiveness, and moisture content of the material will help you determine the ideal crusher specifications, including crushing chamber design and the type of liner materials needed for optimal performance.

Another essential aspect to consider is the capacity and output required for your project. Depending on the scale of your operation, you may need a crusher that can handle a higher throughput to meet production demands. Evaluating the desired output size is also crucial, as it will influence your choice of cone crusher type. It is important to consider any regulatory requirements or operational constraints that may impact your project. By thoroughly analyzing these application requirements, you can make a more informed decision when selecting a cone crusher that aligns with your project's goals and ensures efficient and effective material processing.

When selecting the right cone crusher for your project, it's essential to evaluate key performance metrics, such as capacity, efficiency, and size reduction capability. Capacity refers to the amount of material the crusher can process within a certain timeframe. It's crucial to match the crusher's capacity with your production requirements—too low, and you could experience bottlenecks; too high, and you may incur unnecessary costs.

Efficiency is another critical metric to consider, as it influences the operational costs and the overall productivity of your project. A highly efficient cone crusher will maximize output while minimizing energy consumption. Look for models that offer innovative design features, such as optimized crushing chambers and advanced automation, which enhance operational efficiency.

Tips: Always assess your material characteristics, such as hardness and abrasiveness, as these factors can impact performance. Additionally, regularly maintain and inspect your equipment to sustain optimal efficiency over time. Lastly, consider the size reduction aspect, as it plays a vital role in ensuring that the material meets specific grading requirements. Properly sizing your cone crusher will not only improve the quality of the end product but also reduce the need for additional processing steps, thus saving time and resources.

When selecting a cone crusher for your project needs, maintenance and support considerations play a crucial role in ensuring long-term operational efficiency. One of the primary factors to assess is the ease of maintenance. A well-designed cone crusher should allow for straightforward access to critical components to simplify routine check-ups, part replacements, and repairs. This accessibility minimizes downtime, allowing your project to maintain productivity levels.

In addition to ease of maintenance, the availability of support services is essential. Reliable manufacturers often provide comprehensive support, including training for operators and maintenance personnel, as well as accessible resources for troubleshooting. Understanding the logistics of spare parts availability is equally important; prompt access to replacement parts can prevent extended periods of inactivity. Therefore, when making a decision, it's vital to evaluate not just the initial purchase price, but also the long-term maintenance requirements and the level of support that will be available throughout the lifespan of the equipment.