-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

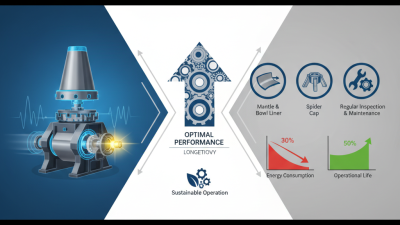

Choosing the right Bowl Liner for your Cone Crusher can be a daunting task. Experts in the industry emphasize the importance of this decision. John Smith, a noted engineer in crushing technologies, once said, “The right bowl liner can significantly enhance productivity and reduce downtime.” His insight underscores the impact of selecting suitable materials and designs.

When considering Bowl Liner options, multiple factors play a role. Factors include the material's hardness, wear resistance, and compatibility with the crusher's mantle. Each choice affects the crusher's efficiency and overall lifespan. It's essential to understand how each liner shape interacts with your specific crushing needs.

Sometimes, the choices are not as clear-cut as they seem. A liner that works well in one scenario may fail in another. Some liners may contribute to excessive wear or even frequent breakdowns. Reflection on operational demands is key to making an informed decision. Balancing cost and quality may lead to trade-offs. Careful analysis of your Crusher's performance is crucial for the best outcome.

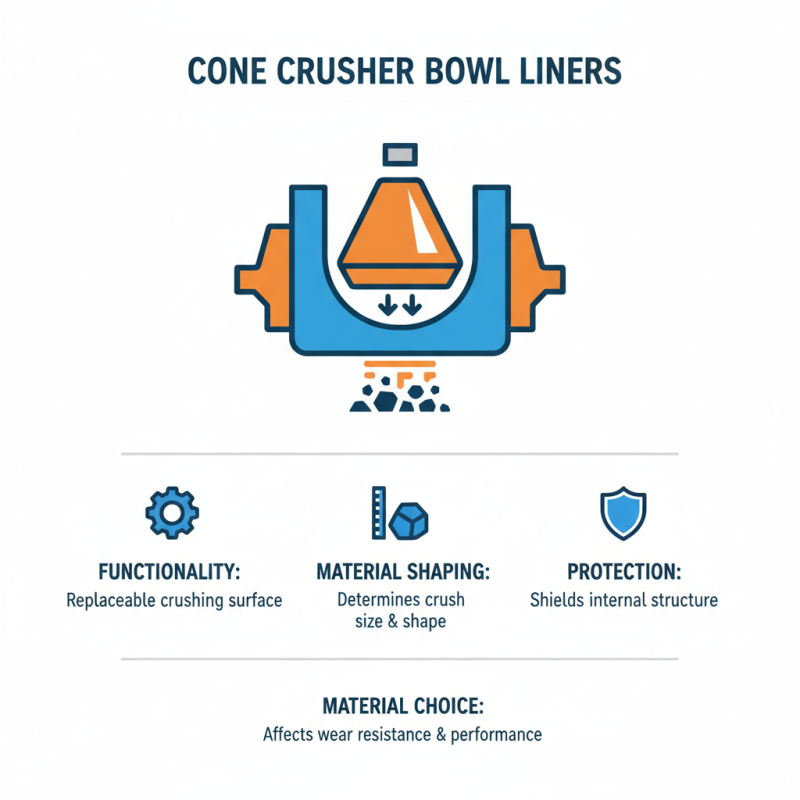

Bowl liners play a critical role in the functionality of cone crushers. They are the replaceable surfaces where the crushed material comes into contact. These liners help create the desired crush size and shape, while also protecting the inner structures of the crusher. The material choice for the bowl liner is important since it directly affects wear resistance and overall performance.

Choosing the right bowl liner requires careful consideration of several factors. For instance, the type of materials being crushed can dictate the liner’s composition. Different applications may prefer various hardness levels. Regular wear patterns can also impact performance; sometimes, even slight adjustments to the liner can lead to significant improvements. Analyzing these patterns is essential, as ignoring them can result in inefficient crushing and increased operational costs.

It’s also worth noting that the installation process can be a bit tricky. A poorly aligned bowl liner can cause uneven wear or even damage to the equipment. Although most guidelines exist, real-world applications can vary. This is an area that demands attention and adjustment. Reflecting on past installations can yield insights for future decisions. Every experience counts in finding the right balance for your specific needs.

When selecting bowl liners for your cone crusher, several key factors come into play. One crucial aspect is the material of the liner. Different materials offer varying levels of wear resistance and durability. For instance, high manganese steel excels at absorbing impact and tensile strength. However, it may not perform well in abrasive environments. Evaluate the specific conditions of your operation to make informed choices.

Another factor to consider is the profile of the liner. The bowl liner's design impacts the flow of material through the crusher. A well-designed profile can lead to increased efficiency and reduced energy costs. Pay attention to the geometry and thickness. Some may be too thick, causing unnecessary wear. Others might be too thin, leading to rapid depletion and failure. Testing different profiles in your specific application could provide valuable insights.

Cost is also a significant component. While investing in high-quality liners can offer longevity and performance, navigating budget constraints can be challenging. Sometimes, cheaper options result in higher maintenance costs. You may find that balancing initial costs with long-term value is a complex task. Regularly review your selections for adaptability to your evolving requirements.

Choosing the right bowl liner for a cone crusher is crucial for optimal performance. The liner material significantly affects crushing efficiency and wear resistance. Common materials include manganese steel and alloyed cast iron. Each has unique properties that influence durability and output.

Manganese steel offers high impact strength. It can withstand heavy loads, making it suitable for high-attrition applications. However, it may wear out faster in less abrasive environments. On the other hand, alloyed cast iron provides good wear resistance but at the cost of lower toughness. Its performance might decline under extreme conditions.

Understanding your crushing environment is key. Do you often process hard rocks? Think about manganese steel. Working with softer materials? An alloyed cast iron liner might suffice. It's essential to balance performance and lifespan. Evaluating the specific needs of your operation can prevent costly mistakes. Remember, what works for one operation may not work for another.

| Material Type | Hardness (HRC) | Wear Resistance | Impact Resistance | Typical Applications |

|---|---|---|---|---|

| High Chrome Iron | 58-65 | Excellent | Moderate | Mining, Quarrying |

| Manganese Steel | Hadfield Grade (around 12-14) | Good | Excellent | Aggregate Production |

| Alloy Steel | 50-60 | Fair | Good | Recycling, Foundries |

| Ceramic Composite | N/A | Excellent | Moderate | High Abrasive Materials |

When analyzing bowl liner profiles for cone crushers, efficiency is key. The shape of the liner impacts crushing performance significantly. A study indicated that an optimal liner shape can improve efficiency by up to 10%. Patterns that enhance material flow can reduce blind spots within the crushing chamber. This leads to a more uniform product and better throughput.

Different profiles, such as standard and long throw, are designed for specific applications. For instance, a longer throw can lead to increased fines. However, it may also risk overload, which could cause damage. Adjusting the concavity and angle of the liner can fine-tune performance, but it may take time to find the exact fit.

The right liner choice depends on various factors. Material type plays a crucial role. Harder materials often require different profiles than softer ones. Some users overlook the importance of regular testing and adjustments. Continuous monitoring can identify wear patterns. This reflection can help in making informed decisions for future upgrades.

This chart illustrates the efficiency percentages of different bowl liner shapes used in cone crushers. The data suggests that concave liners offer the highest efficiency, while flat liners provide the lowest. Understanding these metrics can help in selecting the optimal liner shape for your applications.

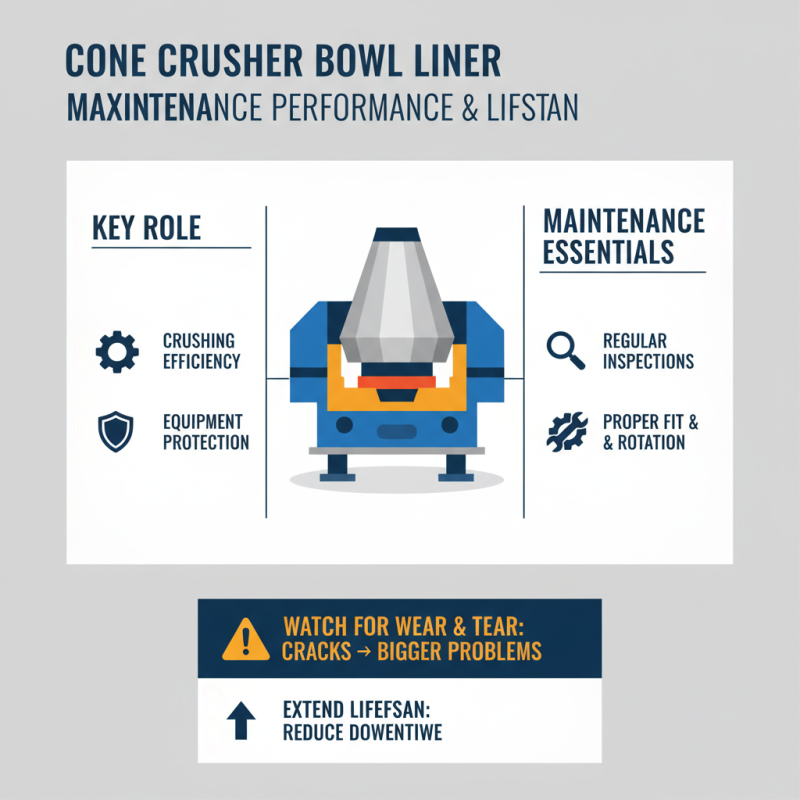

Bowl liners play a crucial role in the performance of cone crushers. Proper maintenance can significantly extend their lifespan. Regular inspections are essential. Look for signs of wear and tear. Small cracks can become bigger problems over time.

Tip: Keep your cone crusher clean. Dirt and debris can lead to increased wear. Cleaning the bowl liners regularly can help prevent unnecessary damage. Use the right tools for cleaning. Avoid aggressive techniques that could scratch the surface.

Another useful strategy is to monitor the operating conditions. Ensure the crusher isn't overloaded. Overloading can accelerate wear. Listen for strange noises. Unusual sounds may indicate misalignment. Address issues immediately to avoid further damage.

Tip: Schedule routine maintenance checks. A few hours spent on maintenance can save you from expensive repairs. Also, consider investing in a good monitoring system. It can help track performance and wear.