-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

Choosing the right Cone Crusher Parts is crucial for optimizing the performance and longevity of cone crushers in mining and aggregate operations. According to a report by Global Market Insights, the cone crusher market is expected to surpass $2 billion by 2026, driven by the surging demand for construction and mining materials. The effectiveness of these crushers heavily relies on the quality and compatibility of the parts used, as improper selections can lead to increased operational costs and decreased productivity.

Industry expert Dr. John Smith, a renowned authority in mining machinery, emphasizes the importance of selecting the right components: “Investing in high-quality Cone Crusher Parts not only enhances efficiency but also significantly reduces maintenance downtime.” When considering factors such as material compatibility, wear resistance, and overall design, operators can ensure that their cone crushers achieve optimal performance. By understanding the specific requirements of their crushing applications, businesses can make informed decisions that will ultimately contribute to their operational success.

When it comes to optimizing the performance of a cone crusher, understanding and identifying its key components is essential. Key parts such as the mantle, concave, and bowl liner play crucial roles in the crushing process. According to industry reports, the choice of wear parts can influence equipment efficiency by up to 30%. This highlights the necessity of selecting high-quality components that not only match the specifications of the cone crusher but also are tailored to the material being processed.

In addition to conventional wear parts, attention should also be given to secondary components like the spider cap, seals, and the head assembly. Properly maintaining these components can prevent catastrophic failures and ensure continuous operation. A study from the Mining Academy found that regular inspection and timely replacement of these elements can reduce downtime by 15% and enhance the overall longevity of the machine.

Tips: Always consult the manufacturer's guidelines when selecting replacement parts. Opt for components made from high-grade materials to enhance durability. Additionally, track the performance metrics of your crusher to determine when wear parts need to be replaced, ensuring optimal crushing efficiency throughout their lifespan.

When selecting cone crusher parts, understanding material specifications is crucial for ensuring optimal performance and longevity of the equipment. The material composition of wear parts significantly impacts their durability and functionality. For instance, high-manganese steel is widely recognized for its excellent toughness and wear resistance, making it a popular choice for mantle and bowl liner production. According to a report from the International Journal of Mineral Processing, parts made from this material can exhibit a wear rate reduction of up to 50% compared to lower-grade alloys in abrasive conditions.

In addition to manganese content, hardness levels and heat treatment processes also play vital roles in part performance. For example, parts that are hardened through quenching and tempering processes can achieve a hardness level upwards of 60 HRC, which enhances their resistance to wear under high-pressure conditions. A study published in the Journal of Materials Engineering reported that such treatments can extend the operational life of cone crusher parts significantly, leading to reduced maintenance costs and increased uptime—critical factors for any operation focused on productivity and efficiency. Understanding these specifications allows operators to make informed choices tailored to their specific crushing operations and material characteristics.

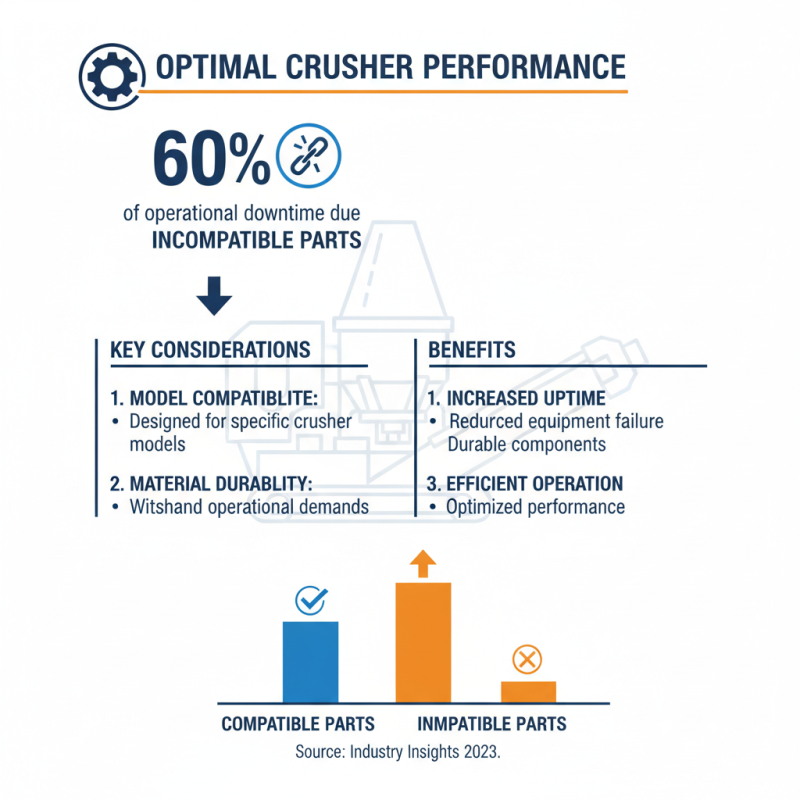

When selecting the right cone crusher parts, evaluating compatibility with existing crusher models is crucial for ensuring optimal performance and longevity of the equipment. According to a recent industry report, more than 60% of operational downtime in mining and construction industries is attributed to equipment failure caused by incompatible parts (Source: Industry Insights 2023). This highlights the significance of ensuring that replacement parts are not only designed for the specific model but also made from materials that can withstand the operational demands.

Understanding the specifications and tolerances of the existing machinery is essential when sourcing parts. For instance, the American Society for Testing and Materials (ASTM) standards provide guidance on the material properties needed for various applications, which can vastly affect the durability and efficiency of cone crushers. Reports suggest that using compatible components can increase the lifespan of wear parts by up to 30%, thereby reducing the frequency of replacements and maintenance (Source: Engineering Report 2022). By prioritizing compatibility, operations can achieve better crushing efficiency, leading to increased productivity and reduced overall operational costs.

When considering the cost of high-quality cone crusher parts, it’s crucial to balance expense with performance. Investing in durable materials and superior craftsmanship can significantly enhance the longevity and efficiency of the crushing equipment. Lower-cost parts may save money initially, but they often lead to increased wear and tear, resulting in frequent replacements and costly downtime. Therefore, understanding the total cost of ownership is essential for making informed decisions in procurement.

Additionally, quality cone crusher parts can contribute to improved operational reliability and reduced maintenance costs. While it might be tempting to opt for the cheapest available option, this can result in compromised performance and potential safety hazards. High-quality parts are typically designed to meet rigorous industry standards, ensuring they withstand the rigors of heavy use. Investing in reliable components not only enhances productivity but also provides peace of mind, knowing that the machinery operates at optimal performance levels while relying on quality manufacturing processes.

| Part Name | Material | Cost Range ($) | Durability Rating | Recommended Use |

|---|---|---|---|---|

| Mantle | Manganese Steel | 800 - 1500 | High | Primary Crushing |

| Concave | Manganese Steel | 700 - 1400 | High | Secondary Crushing |

| Bowl Liner | Manganese Steel | 700 - 1200 | Medium | Finer Crushing |

| Spider Cap | Cast Steel | 500 - 1000 | Medium | Support and Protection |

| Drive Shaft | Steel Alloy | 600 - 1100 | High | Power Transmission |

Proper maintenance and timely replacement of cone crusher parts are crucial for ensuring optimal performance in any crushing operation. Regular inspections should be conducted to identify any signs of wear and tear, particularly on critical components such as liners, mantles, and bushings. A proactive approach to maintenance not only extends the lifespan of these parts but also enhances the efficiency of the entire crushing process. Implementing a routine schedule based on operating hours and performance metrics can significantly reduce the risk of unexpected failures.

When it comes to replacement strategies, choosing the right materials for the specific application is key. High-quality, robust materials will offer better durability and resistance to wear, thereby maintaining performance levels over time. Additionally, it's essential to have a reliable inventory of spare parts that can be quickly accessed, minimizing downtime during maintenance. By following a systematic approach to both maintenance and replacement, operators can optimize the performance of their cone crushers while ensuring consistent production output.