-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

When it comes to optimizing the performance and longevity of jaw crushers, selecting the appropriate swing jaw plates is crucial. John Smith, a renowned expert in the field of crusher engineering, emphasizes, "The right swing jaw plates for jaw crusher not only enhance productivity but also significantly reduce wear and maintenance costs." This statement underscores the importance of choosing swing jaw plates that are specifically designed to meet the unique demands of your crushing operations.

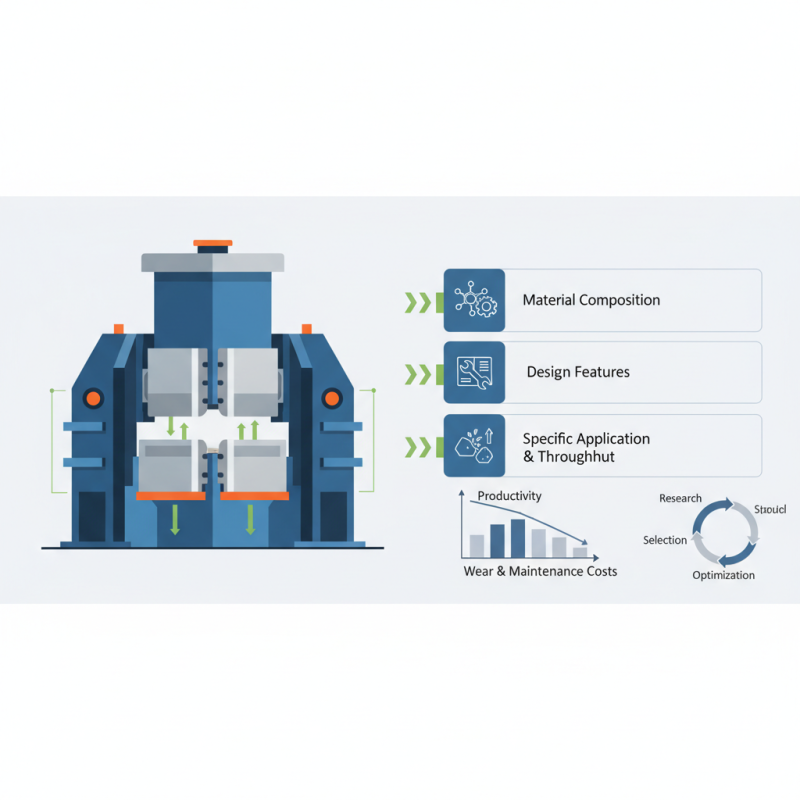

Selecting swing jaw plates for jaw crushers involves understanding various factors including material composition, design features, and the specific application in which the crusher will be utilized. High-quality swing jaw plates are essential not only for the efficiency of the crusher itself but also for the overall success of the material processing operation. As jaw crushers continue to evolve, the demand for innovative and durable swing jaw plates has never been higher, making it essential for industry professionals to stay informed about the latest advancements in materials and design strategies.

Furthermore, the right selection can lead to improved throughput and decreased downtime. Therefore, it is imperative for operators and maintenance teams to invest time in researching and understanding the diverse options available in the market. By doing so, they can ensure that their choice of swing jaw plates for jaw crushers aligns perfectly with their operational needs and industry standards.

The swing jaw plates play a crucial role in the operation of jaw crushers, serving as the primary interface between the moving and stationary elements during the crushing process. Made typically from high manganese steel, these plates are designed to withstand the intense wear and stress associated with crushing hard materials. As the swing jaw moves back and forth, it generates a compressive force that breaks down the material fed into the crusher, making the selection of appropriate swing jaw plates essential for optimal performance and efficiency.

Understanding the functionality of swing jaw plates is vital in ensuring the longevity and reliability of a jaw crusher. The design and thickness of these plates can significantly impact the crushing force and the material's final size. An ideal swing jaw plate should not only provide effective crushing but also withstand wear and fatigue over time, which is why manufacturers often emphasize the importance of matching the material properties to the specific application. Additionally, proper alignment and maintenance of the swing jaw plates contribute to the overall effectiveness of the jaw crusher, maximizing output while minimizing operational costs.

When selecting swing jaw plates for a jaw crusher, evaluating the material composition is essential for ensuring optimal performance and longevity. The materials used in manufacturing swing jaw plates can greatly influence their wear resistance, strength, and overall durability. Typically, common material compositions include high-manganese steel and various alloys that enhance hardness and toughness. High-manganese steel is preferred for its ability to work-harden under impact, making it ideal for applications involving abrasive materials.

In addition to wear resistance, the precise chemical properties of these materials should be examined. Elements such as carbon, manganese, and chromium play critical roles in enhancing the physical characteristics of the swing jaw plates. For instance, a higher carbon content usually results in increased hardness, while manganese contributes to tensile strength and ductility. It is also necessary to consider the specific requirements of the crushing application, as different materials may be better suited for specific types of rocks or aggregates. Therefore, a thorough analysis of material composition not only aids in minimizing wear and tear but also improves the efficiency and productivity of the jaw crusher.

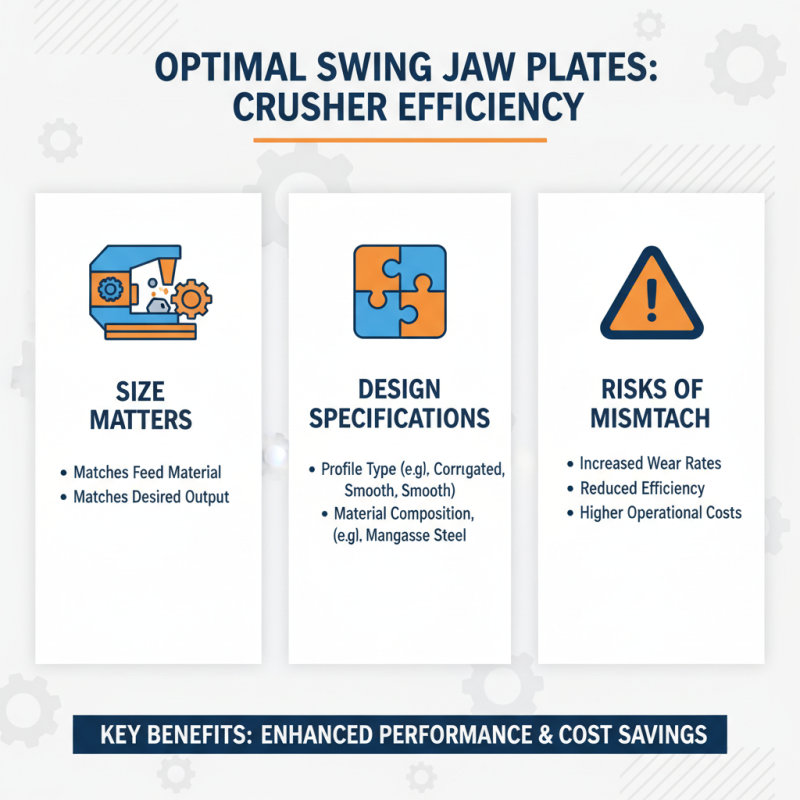

When selecting the right swing jaw plates for your jaw crusher, understanding size and design specifications is crucial. The swing jaw plate plays an essential role in the crushing process, directly affecting the machine's performance and efficiency. It is vital to ensure that the size of the plates matches the size of the feed material and the desired size of the output. According to industry reports, a mismatch in sizes can lead to increased operational costs due to higher wear rates and reduced efficiency.

When assessing design specifications, consider factors such as material composition and hardness. The choice of material impacts durability and how well the plates can withstand the forces exerted during crushing. Harder materials, while more resilient, can also lead to increased wear on other components. The use of advanced modeling techniques can help analyze stress distribution on jaw plates, which aids in selecting the optimal design.

**Tip:** Conduct periodic wear analyses of existing swing jaw plates to gather data on performance and lifespan across various material types. This insight can guide future selections based on actual performance metrics.

Incorporating the right design elements, such as curvature and profile, can enhance the crushing action and lead to a more efficient process. Analysts recommend utilizing computer-aided design (CAD) tools to simulate crushing scenarios, allowing for the identification of ideal specifications tailored to unique operational needs.

**Tip:** Collaborate with engineering experts to leverage their insights into the latest trends in swing jaw plate design and material innovations, ensuring that your choices remain aligned with industry best practices.

When it comes to selecting high-quality swing jaw plates for your jaw crusher, identifying the right manufacturer is crucial. A reputable manufacturer will prioritize the use of premium materials and advanced manufacturing techniques, ensuring that the swing jaw plates can withstand the demanding conditions of crushing operations. Look for companies that demonstrate a commitment to quality assurance and offer detailed specifications and test results for their products. This transparency not only reflects their integrity but also helps you make an informed decision about the durability and performance of the plates.

Additionally, the manufacturer's experience in the industry plays a significant role in the overall quality of their products. A company with a long-standing reputation is more likely to have refined its processes and established a reliable supply chain, ensuring consistent quality across their offerings. Researching customer reviews and case studies can provide valuable insights into the performance of their swing jaw plates and their ability to meet specific operational needs. By choosing a manufacturer that combines experience, quality assurance, and positive customer feedback, you can ensure the best fit for your jaw crusher requirements.

Maintaining swing jaw plates is crucial for ensuring the optimal performance of your jaw crusher. Regular inspection is key; operators should check for wear and tear, as well as any signs of cracking or deformation. Allowing wear to progress unchecked can lead to more significant damage not only to the plates but to the entire crusher assembly. Keeping a maintenance log can help track the condition of the swing jaw plates and predict when replacements will be needed, thus minimizing unexpected downtime.

Another effective maintenance tip is to ensure proper lubrication of the swing jaw assembly. Adequate lubrication reduces friction between components, which can significantly extend the lifespan of the jaw plates. Using the correct type of lubricant as specified in the equipment guidelines is important to prevent excessive wear due to inadequate protection. Additionally, operators should ensure that the crushing chamber is not overloaded, as this can put undue stress on the swing jaw plates. By following these maintenance practices, operators can enhance the durability and efficiency of their jaw crushers.

| Material Type | Hardness (HRC) | Wear Resistance | Typical Application | Estimated Lifespan (Hours) |

|---|---|---|---|---|

| Manganese Steel | Hadness 12-14 HRC | High | Primary Crushing | 1500-2500 |

| High Carbon Steel | Hardness 60-65 HRC | Medium | Secondary Crushing | 1000-2000 |

| Alloy Steel | Hardness 50-55 HRC | High | Recycling Operations | 1200-2200 |

| Cast Iron | Hardness 30-35 HRC | Medium | Low Impact Applications | 800-1500 |