-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

When it comes to maximizing the efficiency and performance of a jaw crusher, selecting the right wear parts is crucial. Jaw Crusher Wear Parts play an integral role in the machine's overall functionality, as they are specifically designed to withstand the immense forces and abrasion inherent in crushing operations. Understanding the various options available and their distinct features can significantly impact not only the lifespan of these components but also the overall productivity of the crushing process.

The appropriate selection of Jaw Crusher Wear Parts promotes optimal crushing efficiencies and minimizes downtime, ultimately enhancing operational sustainability. Factors such as material composition, design, and fit must be carefully considered to achieve the best results. Additionally, the choice of wear parts can influence the maintenance routines and financial implications associated with jaw crusher operations. As crushing environments vary widely, it becomes essential for operators to tailor their selections to meet the specific demands of their applications.

In this guide, we will explore the critical aspects of selecting Jaw Crusher Wear Parts, focusing on the key considerations that drive efficiency and performance. By equipping yourself with the right knowledge, you will be better positioned to make informed choices that lead to superior outputs and reduced operational costs.

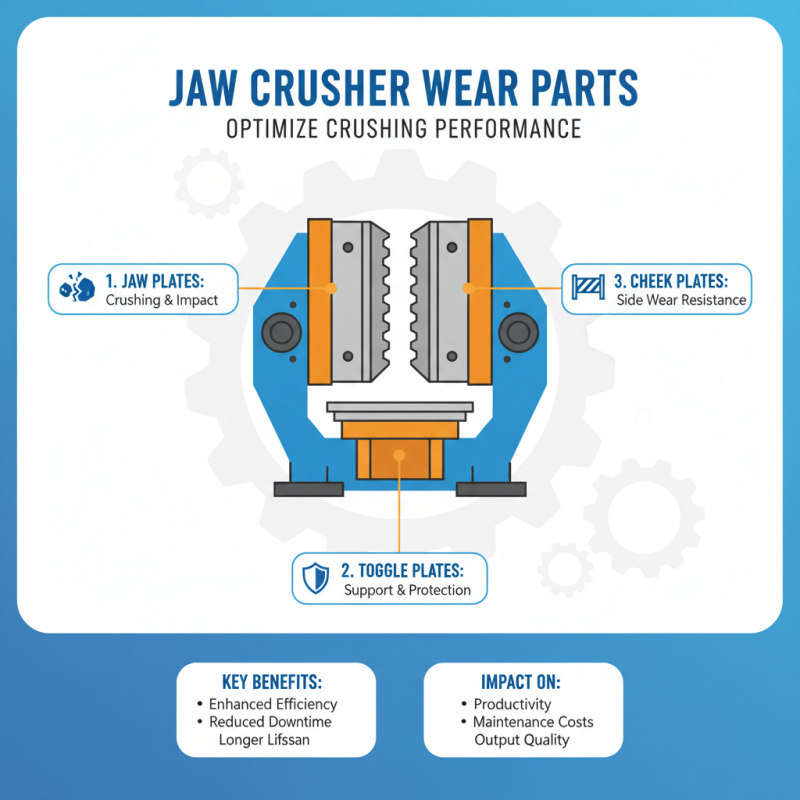

Jaw crusher wear parts are essential components that significantly influence the efficiency and performance of crushing operations. Understanding the different types of wear parts is vital for making informed choices that enhance productivity and reduce downtime. The primary wear parts in a jaw crusher include the jaw plates, toggle plates, and cheek plates. Each of these components is designed to withstand extreme wear while delivering optimal crushing capabilities.

Jaw plates, typically made from high manganese steel, are critical for crushing materials. They are the main points of contact with the material being processed and come in various profiles to accommodate different materials and sizes. Proper selection and timely replacement of jaw plates are crucial to maintaining the crushing efficiency. Cheek plates serve to protect the sides of the crusher from wear and are often made from similar, durable materials. Meanwhile, toggle plates, which provide a safety mechanism during uncrushing, vary in thickness to ensure the right balance of strength and flexibility.

Choosing the right wear parts involves not only understanding these components but also considering factors such as the material being crushed, desired output size, and crushing environment. Each application may require a specific type of jaw plate profile or thickness to maximize efficiency and prolong the life of the wear parts. Regular inspection and proactive replacement policies can significantly improve operational efficiency and minimize unexpected maintenance costs.

When selecting wear parts for jaw crushers, several factors should be analyzed to ensure maximum efficiency and longevity of the equipment. Firstly, material composition is crucial. Opting for high-quality materials that offer durability and resistance to wear can significantly affect the performance of the wear parts. For instance, parts made from manganese steel are known for their toughness and work-hardening properties, making them suitable for heavy-duty applications. Understanding the specific material requirements based on the type of material being crushed can lead to better performance and reduced replacement costs.

Another essential factor to consider is the design of the wear parts. The shape and profile of jaw plates can influence the efficiency of the crushing process. Parts with optimized geometries can enhance the material flow, enabling better crushing action and leading to a more even wear pattern. Additionally, compatibility with the existing machinery should be ensured, as parts designed to fit perfectly with the jaw crusher can improve operational performance and reduce maintenance issues. Evaluating these elements can lead to smarter purchasing decisions and improved overall productivity in crushing operations.

This bar chart illustrates the wear resistance of different types of jaw crusher wear parts, providing insight into selecting the most efficient materials to maximize performance and longevity in mining operations.

When selecting wear parts for jaw crushers, the choice between steel and other alloys plays a crucial role in maximizing efficiency. Steel is the traditional choice, known for its high tensile strength and durability. It can withstand significant impact forces, making it suitable for heavy-duty applications. However, its performance can be limited in highly abrasive environments, where the wear rate can be substantial, leading to increased downtime and maintenance costs.

On the other hand, various alloys offer distinct advantages in specific applications. For instance, high-manganese steel, engineered for high impact strength and resistance to wear, is particularly effective in minimizing wear during crushing operations. Other alloys, such as chrome-molybdenum or titanium-carbide composites, can enhance the hardness and wear resistance of the parts, further extending their lifespan in abrasive conditions. Each material's unique properties must be carefully considered in relation to the specific material being processed and the operating environment to achieve the best balance of wear resistance and overall efficiency.

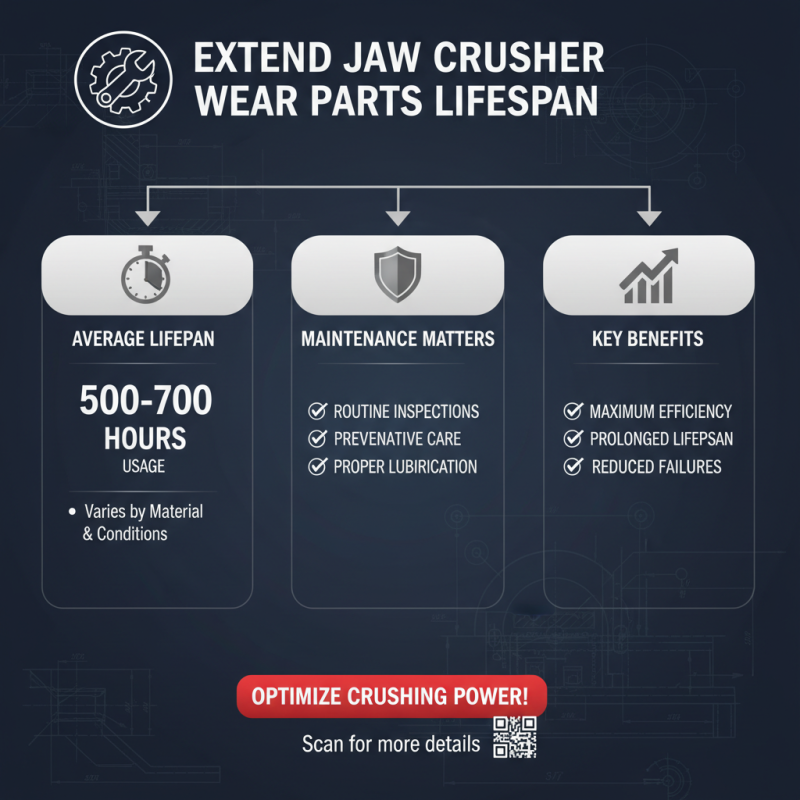

Maintaining jaw crusher wear parts is crucial for ensuring optimal performance and longevity. According to industry reports, the average lifespan of jaw crusher wear parts can significantly vary, often ranging from 500 to 700 hours of usage depending on material type and operational conditions. To maximize efficiency and prolong this lifespan, routine inspections and preventive maintenance are essential. Regularly checking for signs of wear, misalignment, and ensuring proper lubrication can help mitigate unexpected failures and optimize the crushing process.

Moreover, employing the right materials for wear parts can have a profound impact on their durability. High-quality manganese steel is commonly used in the manufacturing of jaw plates due to its excellent wear resistance and ability to withstand high impact forces. Studies suggest that using wear parts manufactured from advanced alloys can improve wear life by up to 30%, translating into significant cost savings and reduced downtime. Implementing a well-planned maintenance schedule that includes timely replacements of worn components can enhance overall operational efficiency, allowing for uninterrupted production and better material processing.

When it comes to optimizing the functionality of jaw crushers, the choice of wear parts is pivotal. In evaluating cost versus performance, investing in high-quality wear parts can significantly enhance operational efficiency. According to a report by **Mining Weekly**, using premium-grade manganese steel for jaw crusher liners increases their lifespan by up to 30% compared to standard materials. This extended durability not only reduces the frequency of replacements but also minimizes unexpected downtime, which can be costly for mining operations.

Moreover, the optimal selection of wear parts can influence productivity rates. The **International Journal of Mineral Processing** highlights that quality wear parts can improve the reduction ratio of materials, contributing to higher throughput. For instance, with superior wear parts, crushers are able to maintain consistent product size and reduce the amount of oversize material, translating into better overall output. While the initial investment in quality parts may seem higher, the long-term benefits—including reduced maintenance costs and enhanced production capabilities—make this approach financially sound for mining and aggregate processing companies looking to maximize efficiency.

| Wear Part Type | Material | Cost per Unit ($) | Life Span (Hours) | Performance Rating |

|---|---|---|---|---|

| Jaw Plate | High Manganese Steel | 250 | 1000 | Excellent |

| Cheek Plate | Manganese Steel | 150 | 900 | Good |

| Toggle Plate | Alloy Steel | 100 | 700 | Fair |

| Liner Plate | High Chrome Iron | 200 | 800 | Very Good |

| Fixed Jaw | High Manganese Steel | 300 | 1200 | Excellent |