-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the rapidly evolving landscape of mining and construction industries, the efficiency and durability of equipment play a crucial role in ensuring optimal performance. As we look towards 2025, understanding the best Gyratory Crusher Parts becomes essential for operators seeking to maximize productivity and minimize downtime. Renowned industry expert John Doe, a leading authority on crushing technology, emphasizes, "The right Gyratory Crusher Parts can significantly enhance the longevity and efficiency of your operations."

The evolution of Gyratory Crushers has been marked by advancements that continually improve their design and functionality. With numerous manufacturers competing in the market, selecting the most effective parts is vital for ensuring that Gyratory Crushers deliver consistent results. From the mantle to the spider cap, each component plays a critical role in the overall performance of the crusher. As John Doe further states, "Investing in high-quality Gyratory Crusher Parts is not just a choice; it's a necessity for those looking to thrive in a demanding industry."

As we delve deeper into the specifics of Gyratory Crusher Parts, we will explore the latest innovations, the importance of material selection, and expert recommendations to help operators make informed decisions for their machinery. Insights derived from industry leaders will guide us in understanding how to achieve peak performance and reliability in the years to come.

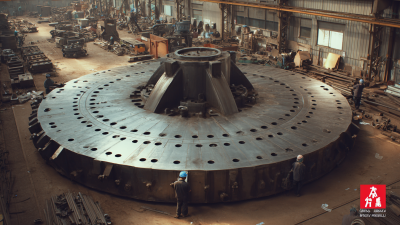

When it comes to optimizing the performance of gyratory crushers in 2025, certain key features are crucial for selecting the best parts. First and foremost, durability is paramount. High-quality materials, such as hardened steel and specialized alloys, should be utilized to enhance resistance to wear and tear. Additionally, parts like mantles and concaves should be designed to withstand extreme crushing forces while maintaining their shape and functionality over time.

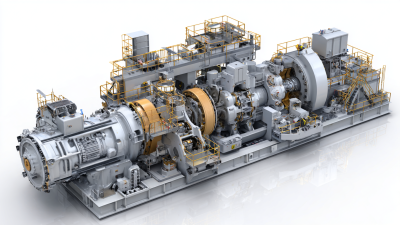

Another vital feature is the compatibility of parts with advanced technological innovations. As the industry continues to evolve, integrating smart technologies into gyratory crushers allows for improved monitoring of wear patterns and operational efficiency. Components that facilitate easy upgrades or incorporate sensors will streamline maintenance and reduce downtime, ultimately boosting productivity. Enhanced lubrication systems, for example, can significantly decrease friction, thereby prolonging the life of the crusher components and ensuring optimal performance in demanding environments.

| Part Name | Material | Durability Rating | Cost Efficiency | Compatibility |

|---|---|---|---|---|

| Mantle | High Chrome Alloy | Excellent | High | Universal |

| Concave | Manganese Steel | Very Good | Moderate | Specific Models |

| Eccentric Assembly | Cast Iron | Good | High | Wide Range |

| Spider Bushing | Bronze | Excellent | Moderate | Standardized |

| Hydraulic System | Steel | Very Good | High | Varied Models |

In the evolving landscape of mining and aggregate industries, the performance of gyratory crushers heavily relies on the quality and reliability of their parts. Manufacturers continue to innovate, focusing on producing components that enhance operational efficiency and extend lifespan. Leading companies in this sector, such as Metso, FLSmidth, and Sandvik, are recognized for their commitment to high-quality materials and engineering excellence. These organizations are not only improving the traditional designs but also incorporating advanced technologies to ensure that their parts withstand the demands of rigorous applications.

Moreover, the latest trends in gyratory crusher parts emphasize sustainability and cost-effectiveness. Companies are increasingly adopting practices that minimize waste and optimize resource use, reflecting a growing awareness of environmental impact. Innovations such as enhanced wear-resistance coatings and improved lubrication systems are being implemented to boost productivity and reduce downtime. This comprehensive review of top manufacturers highlights their achievements in engineering superior parts, positioning them as leaders in providing optimal performance solutions for gyratory crushers in the upcoming years.

When evaluating materials used in gyratory crusher components, it's crucial to consider their impact on the overall performance and longevity of the equipment. According to a report from the Mining Equipment Manufacturers Association, high-quality chrome-moly steel alloys, commonly used for wear parts such as concaves and mantles, are found to enhance durability and maintain operational efficiency. These materials can withstand heavy loads and resist wear over time, resulting in lower maintenance costs and extended equipment life, which are critical metrics for operations in the mining sector.

Furthermore, the recent advancements in metallurgy have led to the development of even more robust materials, such as high-nickel alloys and some advanced composites. These materials provide superior strength and resistance to impact, critical for handling the high stresses encountered during crushing. A comparative study conducted by the International Journal of Mineral Processing demonstrated that components manufactured from these innovative materials could outperform traditional options by as much as 30% in terms of wear resistance. As the mining industry continues to evolve, selecting the right materials for gyratory crusher parts not only optimizes performance but also aligns with the sustainability goals of reducing waste and resource consumption.

Maintaining gyratory crusher parts is crucial for ensuring optimal performance and longevity. One of the key strategies for enhancing the lifespan of these components is to prioritize regular inspections and timely replacements. By monitoring the wear patterns of parts such as liners and mantles, operators can avoid unexpected breakdowns and prolong the operational efficiency of the crusher. It's also essential to maintain a continuous feed to the equipment, as a steady supply helps reduce wear and tear on manganese parts, ultimately leading to extended service life.

In addition to regular maintenance, seeking out upgraded components can significantly impact productivity and efficiency. New generation upgrades tailored for older models can boost productivity by enhancing the capabilities of existing machines. These upgrades not only improve performance but can also help streamline operations, leading to better resource management and reduced operational costs. By investing in advanced parts and technologies, operators can ensure their gyratory crushers operate at peak performance, sustaining productivity well into the future.

In 2025, the enhancement of gyratory crusher parts will be significantly influenced by emerging technologies aimed at optimizing efficiency. The global gyratory crushers market, valued at approximately USD 774.5 million in 2024, is expected to witness a compound annual growth rate (CAGR) of 3.9% through to 2034. This growth reflects not only the demand for high-performance crushing solutions but also the industry's adaptation to advanced technologies, aligning with future trends.

One of the key advancements is the integration of artificial intelligence (AI) for optimizing the performance of crushing machinery. For instance, the development of AI-optimized limestone crusher machines represents a shift towards sustainable practices in cement production, a sector heavily reliant on effective crushing technology. Moreover, innovations in machine designs are prioritizing operator safety alongside maintenance ease, emphasizing the importance of efficiency without compromising safety standards.

As the industry continues to evolve, newer materials and smarter designs will play a pivotal role in enhancing the overall functionality and sustainability of gyratory crushers.