-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

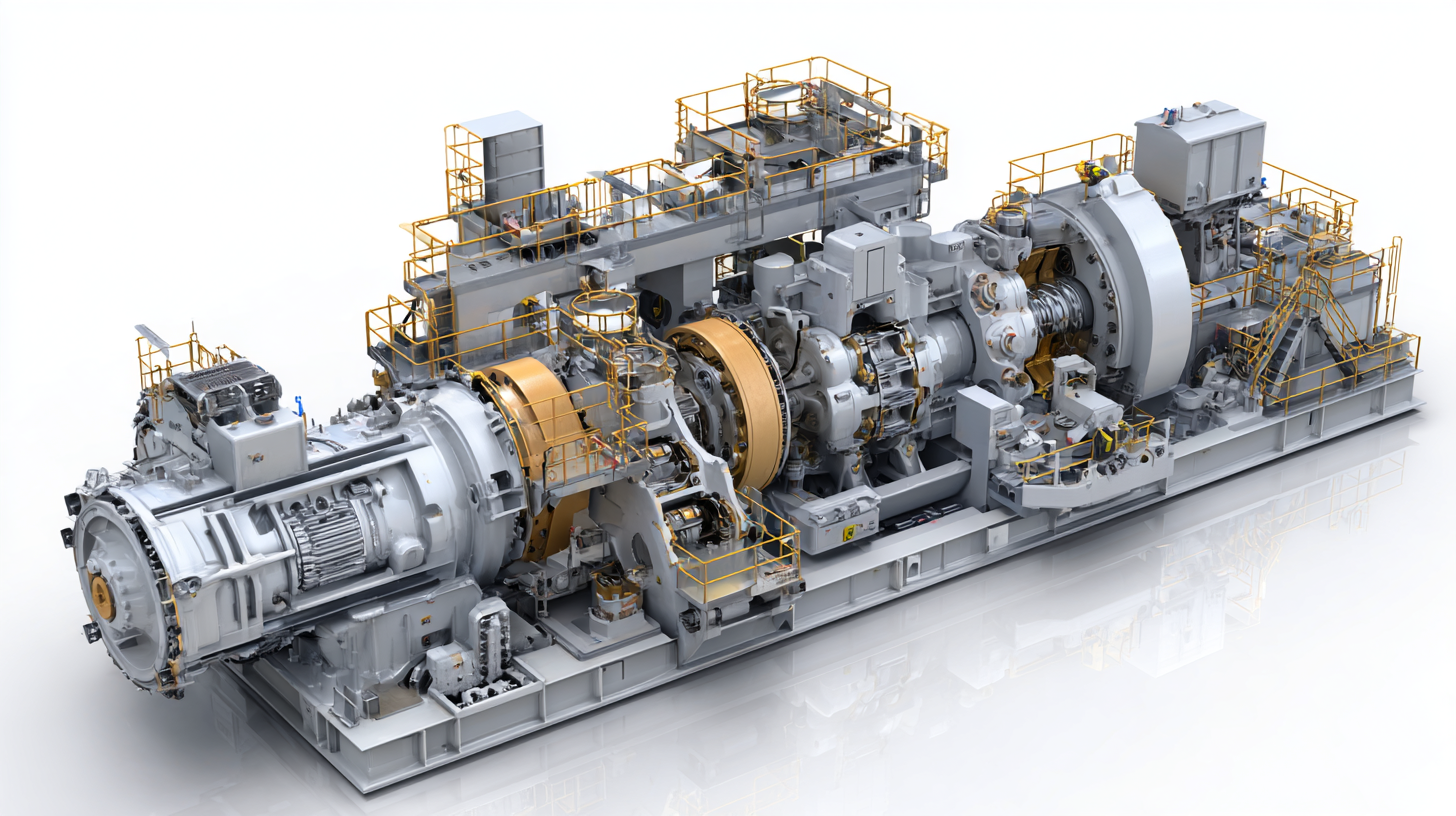

In the mining and aggregate industries, the efficiency and longevity of equipment are paramount, making the selection of high-quality Gyratory Crusher Parts a critical decision for operators. According to a report by Grand View Research, the global cone crusher market is expected to reach USD 2.4 billion by 2025, highlighting the increasing demand for advanced machinery that offers both performance and reliability. After-sales service and maintenance costs play a pivotal role in the total cost of ownership for gyratory crushers, as operators who invest in superior parts often realize significant savings over time. Proper maintenance can reduce downtime by up to 30%, as indicated by a study from the National Institute for Occupational Safety and Health (NIOSH). This blog will explore the advantageous aspects of these services, emphasizing how quality parts not only enhance performance but also lead to substantial operational savings.

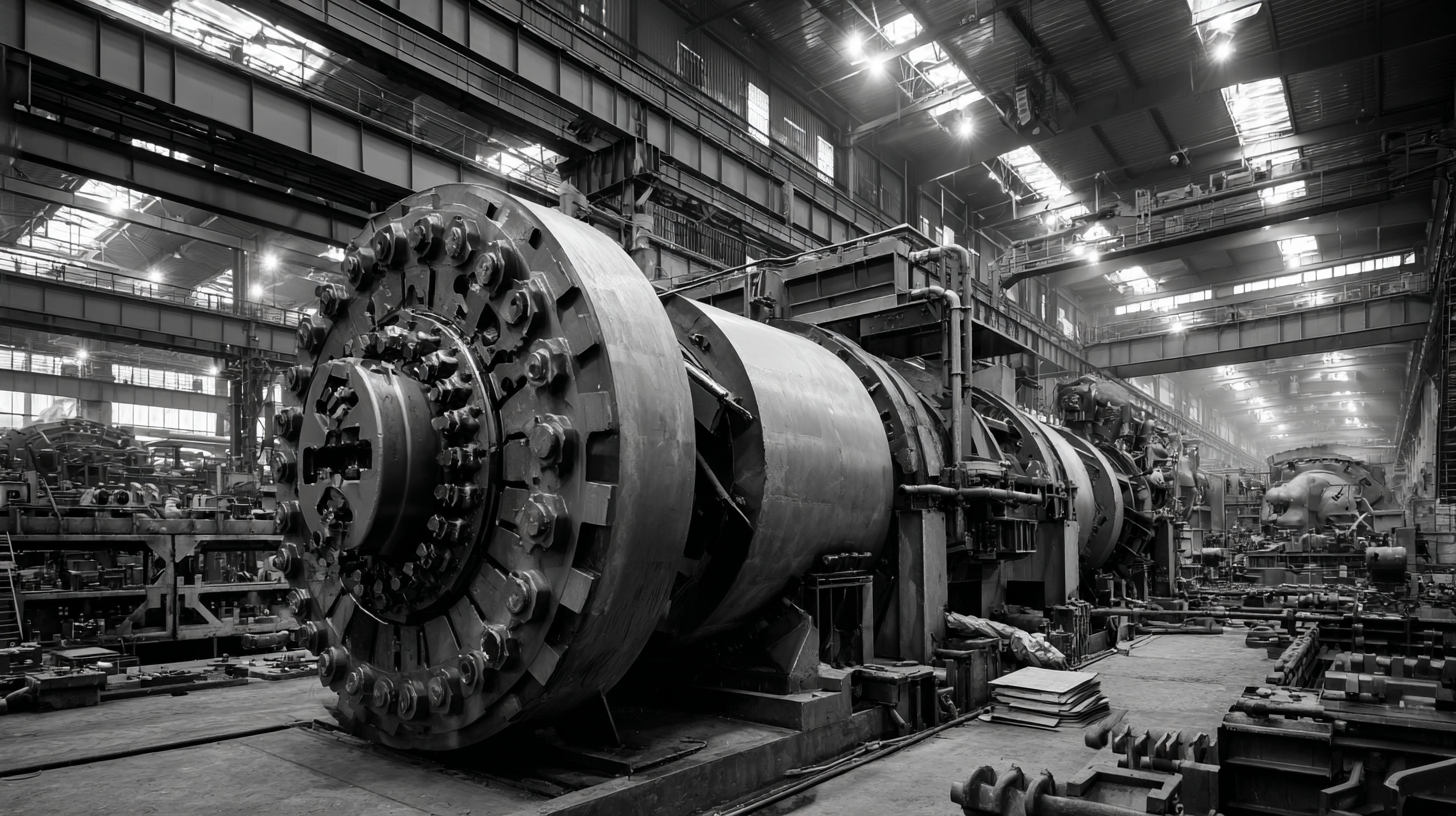

After-sales service is a crucial aspect that significantly impacts the longevity and efficiency of gyratory crushers. It extends beyond mere product delivery; it includes installation support, regular maintenance, and timely repairs. A reliable after-sales service ensures that operators have access to expert knowledge and assistance, which can help in quickly resolving issues that may arise during operation. This proactive approach not only minimizes downtime but also enhances overall productivity, making it a valuable investment for businesses.

Understanding the importance of maintenance costs associated with gyratory crusher parts is also vital for maximizing savings. Regular maintenance can prevent costly breakdowns and extend the lifespan of the equipment. Quality after-sales service provides tailored maintenance schedules and helps operators maintain optimal working conditions. By investing in parts and support from reputable manufacturers, mining operations can benefit from cost-effective solutions that maintain peak performance and reduce long-term expenses.

When selecting a quality gyratory crusher parts manufacturer, it's essential to focus on a few key features that ensure durability and efficiency. First and foremost, look for manufacturers that employ advanced manufacturing techniques and high-grade materials. This not only enhances the lifespan of the components but also minimizes the need for frequent replacements, ultimately contributing to significant cost savings over time.

Tips: Always inquire about the material specifications used in the production of parts. Reputable manufacturers should be transparent about their material choices and backing them with certification to ensure they meet industry standards.

Another critical feature is the availability of comprehensive after-sales service and support. A manufacturer who provides robust maintenance options can greatly contribute to the operational efficiency of your equipment. Ensure that they offer easy access to replacement parts and responsive customer service. This will not only help in minimizing downtime but also facilitate cost-effective maintenance practices.

Tips: Before finalizing your purchase, check customer reviews and testimonials regarding the manufacturer's after-sales service. A track record of responsiveness and accountability can be a good indicator of their reliability.

When investing in gyratory crusher parts, the fundamental equation of cost versus quality always applies. Higher-quality parts might come with a heftier price tag, but they often prove to be more cost-effective in the long run. Premium materials and superior engineering can enhance the durability and efficiency of the crushers, reducing the frequency of replacements and minimizing downtime. This means that operators can access a reliable performance that translates into better productivity and lower operational costs.

On the other hand, opting for cheaper alternatives might seem appealing initially, but these parts tend to wear out faster and may compromise the overall functionality of the equipment. The risk of unexpected failures can lead to significant repair costs and prolonged periods of halted operations.

Therefore, it’s crucial for businesses to evaluate not just the upfront costs but also the lifetime value of the parts they choose. By investing in high-quality gyratory crusher components, companies can ensure they are making a strategic decision that supports their operational efficiency and ultimately contributes to their bottom line.

When it comes to ensuring the longevity of gyratory crusher components, proper maintenance is paramount. Regular inspections can help identify wear and tear before it leads to major failures. One crucial tip is to keep a detailed log of all maintenance activities, which aids in tracking performance trends and planning future maintenance effectively.

Always make sure to monitor the lubrication system. Proper lubrication not only minimizes friction but also prevents overheating, which can damage critical parts. It's advisable to use high-quality lubricants recommended by the manufacturer and to change them at specified intervals. Additionally, keeping the lubrication system free of contaminants will further enhance the life of your gyratory crusher.

Another important aspect is the adjustment of the crushing gap. Regularly checking and adjusting the gap between the crushing surfaces ensures optimal performance and reduces unnecessary stress on the components. A well-maintained crushing gap not only improves efficiency but also extends the overall lifespan of the gyratory crusher parts, ultimately maximizing your investment.

When it comes to investing in a gyratory crusher, the quality of after-sales support can significantly influence not only operational efficiency but also the overall cost-effectiveness of the equipment. The best manufacturers stand out by offering comprehensive after-sales services, including timely maintenance, readily available spare parts, and expert support teams ready to assist at a moment's notice. This commitment to service ensures that downtime is minimized, allowing businesses to focus on maximizing productivity without unnecessary interruptions.

Moreover, leading manufacturers often provide tailored maintenance contracts that align with the specific needs of their customers. These contracts typically include routine inspections, preventive maintenance, and quick access to high-quality replacement parts. Such proactive measures not only extend the lifespan of the equipment but also result in savings that can be reinvested into other critical areas of the operation. By evaluating these after-sales support offerings, companies can make informed decisions about their equipment, ultimately leading to enhanced performance and reduced long-term costs.