-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

The jaw crusher, a cornerstone in mining and aggregate processing, has transformed operations significantly. According to a report by Allied Market Research, the jaw crusher market is expected to reach $2.3 billion by 2026, reflecting its vital role in the industry. Understanding the "Jaw Crusher Working" principles is essential for optimizing performance and ensuring efficiency in operations.

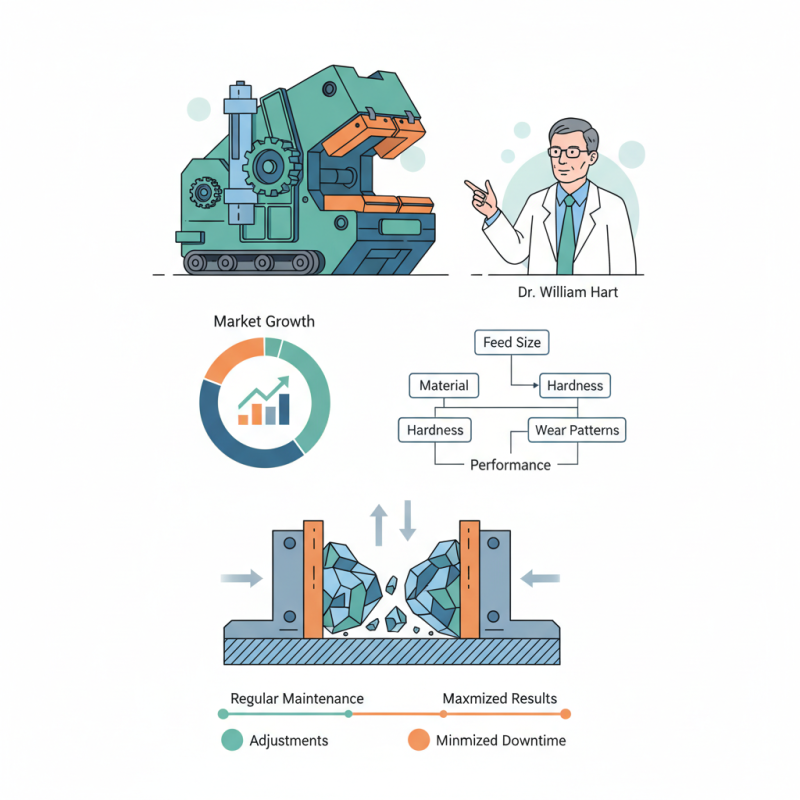

Renowned expert Dr. William Hart states, "The efficiency of jaw crushers directly impacts the overall productivity of crushing plants." His insights highlight the need for a deep understanding of how these machines operate. Jaw crushers rely on compressive forces to break down materials. When set up incorrectly, the machine can experience reduced efficiency and increased wear.

Factors such as feed size, hardness of materials, and wear patterns can alter the expected performance. The nuances of jaw crusher working often lead to unexpected challenges. Regular maintenance and adjustments are crucial for maximizing results and minimizing downtime. The industry must continually reflect on operational processes to adapt to changing demands.

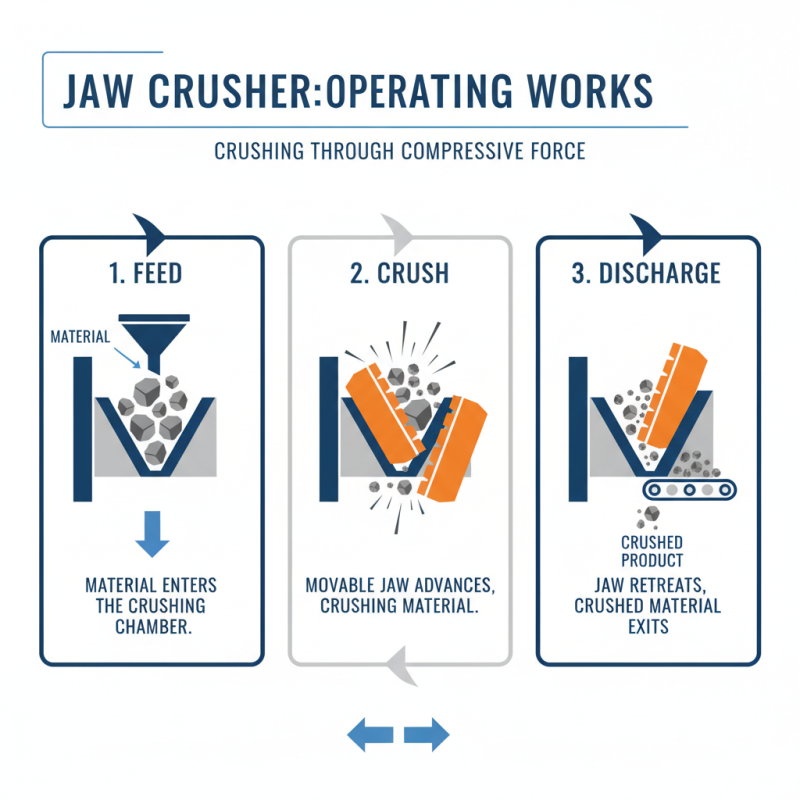

Jaw crushers are vital in mining and construction. They operate using a simple mechanism. The crushing process involves a swinging jaw and a fixed jaw. As the movable jaw swings back and forth, it crushes materials against the fixed jaw. This combination produces a powerful crushing action.

The jaw crusher’s design includes several critical components. These parts include the jaws, the frame, and the pitman. The jaws are usually made of hard steel to withstand wear. According to industry data, about 3,000–5,000 tons of material can be processed daily by a typical jaw crusher. However, not all jaw crushers meet this standard. Some might underperform due to poor design or subpar materials.

Maintenance is crucial for efficiency. Regular inspections can reveal wear and tear. For example, the jaws should be replaced when they lose their sharpness. Ignoring this can lead to reduced performance and increased operational costs. Current reports indicate that failure to maintain equipment can lead to output loss of up to 30%. Such figures highlight the necessity for diligent upkeep in this sector.

Jaw crushers operate on simple principles. They crush materials through compressive force. The movable jaw moves closer to the fixed jaw, creating a gap. This gap allows materials to be broken down. As the movable jaw retreats, crushed material falls down.

The design of the jaw crusher maximizes efficiency. The angle between the jaws affects the size of the crushed materials. A steep angle may lead to larger outputs. However, it can also result in uneven wear. This is a critical detail that needs careful consideration.

Effective material reduction is essential in many industries. It impacts costs and processing times. Proper maintenance is necessary. Neglect can lead to inefficient crushing and costly repairs. Regular inspections help detect wear on the parts. This proactive approach is often forgotten. It’s crucial to remember that small oversights can lead to significant issues in operation.

Jaw crushers are critical in the mining and construction industries. Their efficiency significantly affects production rates and cost. Several factors influence their performance, including material characteristics, crusher design, and operational parameters.

Material properties play a vital role. Harder materials, such as granite, require more energy to crush. According to a recent study, crushing efficiency drops by 15% when processing high-silica materials. Optimal feed size also matters. If the feed is too large or too small, it can lead to increased wear and reduced throughput. It’s essential to maintain the right balance.

Operational parameters can make or break a jaw crusher’s efficiency. The angle of the jaw and the speed of the eccentric shaft impact performance directly. A small adjustment in the nip angle can lead to a significant difference in product size. Some operations overlook these factors, resulting in reduced productivity and higher maintenance costs. Monitoring and adjusting these variables is crucial for maintaining peak performance.

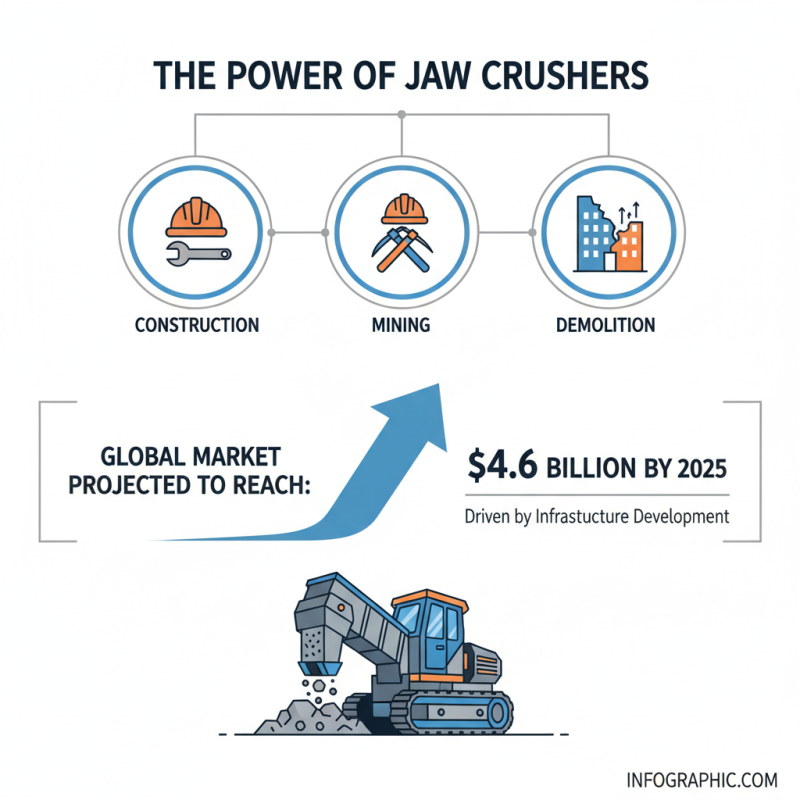

Jaw crushers are essential in various industries. They are primarily used in construction, mining, and demolition. In fact, the global jaw crusher market is expected to grow significantly. By 2025, the market is projected to reach $4.6 billion. This growth is driven by infrastructure development.

Construction sites benefit greatly from jaw crushers. They break down large rocks into smaller, manageable pieces. This process is crucial for creating aggregates used in concrete. In mining, jaw crushers help extract valuable minerals. They crush ore to liberate precious metals. Reports indicate that about 70% of global mining operations utilize crushers.

Demolition projects also rely heavily on jaw crushers. These machines handle concrete and steel structures. A jaw crusher can reduce material volume by up to 80%. However, operators must consider wear and maintenance. Neglecting upkeep can lead to inefficiencies and costly downtime. As the industry evolves, understanding these limitations becomes vital.

The jaw crusher industry is evolving. As new technologies emerge, we see significant trends in design and efficiency. Recent reports suggest that the global jaw crusher market could reach $2.4 billion by 2026. This growth is driven by increasing construction and mining activities worldwide.

Current trends focus on automation and smart technology. Features like advanced sensors and AI are being integrated into jaw crushers. These innovations aim to improve efficiency and reduce downtime. For example, predictive maintenance can decrease unexpected failures significantly. A recent survey indicated that over 70% of industry experts believe automation will enhance productivity in the coming years.

However, with all these advancements, there are still challenges. Many companies struggle to balance innovation with cost. Limited budgets hinder the adoption of the latest technologies. Furthermore, there is a need to address environmental concerns. Sustainable design practices must be prioritized alongside performance improvements. The industry must reflect on these issues to ensure future progress.