-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

In the world of mining and construction, the role of Impact Crusher Wear Parts cannot be overstated. Industry expert John Doe states, "The right wear parts can make or break your equipment’s efficiency." Wear parts are critical components that directly affect the longevity and performance of impact crushers. Selecting these parts requires attention to detail and a deep understanding of the equipment.

Every operation has its challenges. Some struggle with choosing the right materials, while others face frequent breakdowns due to inadequate wear parts. These issues lead to costly downtimes. Properly selected Impact Crusher Wear Parts can significantly reduce maintenance costs and enhance productivity. Yet, many still overlook the impact of wear parts on overall efficiency.

Trade-offs exist. Economic options may seem appealing, but they often sacrifice quality. When durability is compromised, potential gains vanish. Understanding the balance between cost and efficiency is essential. Digging deeper into wear parts can reveal invaluable insights. What works for one operation may not fit another. Knowledge in this area fosters informed decisions, ultimately leading to improved performance and reliability.

Impact crushers play a crucial role in heavy industry, particularly for material processing. These machines deliver high efficiency when crushing rocks and minerals. However, the components within these crushers experience significant wear over time. Understanding wear parts helps in maintaining optimal productivity.

Regular inspections are vital. Common wear parts include blow bars, impact plates, and apron liners. Each of these parts has specific wear symptoms. For example, if you notice excessive vibration or noise, it may signal a problem.

Tips for managing wear parts effectively:

Small adjustments can lead to significant improvements. This reflection will guide you in optimizing equipment life and efficiency.

When discussing impact crusher wear parts, material choice is crucial.

Many manufacturers utilize high chrome white iron due to its excellent durability.

This material withstands heavy impact and is resistant to abrasion. It ensures that parts like blow bars and impact plates last longer in harsh environments.

The performance of an impact crusher heavily depends on the wear parts' quality.

Another common material is manganese steel.

It offers high toughness and ductility.

While it can resist deformation under extreme pressure, it may not perform well in all conditions.

Careful selection of materials helps manufacturers meet specific operational needs.

Sometimes, the right choice might not seem obvious.

Additionally, regular maintenance of wear parts is often overlooked.

Even the best materials wear down over time.

Ensuring timely inspections can prevent unexpected failures.

This proactive approach can save time and costs.

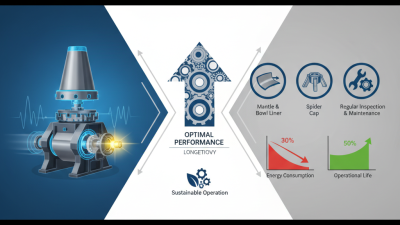

Balancing material properties and maintenance strategies is key to achieving optimal performance.

Abrasion resistance is a crucial factor when considering impact crusher wear parts. It refers to the material’s ability to withstand damage from abrasive materials. High abrasion resistance prolongs the life of wear parts, reducing the need for frequent replacements. This can minimize downtime in operations and save on costs, which is vital for any business.

Choosing the right materials for wear parts can be challenging. Many factors influence their performance. For example, hardness, toughness, and wear mechanisms come into play. It's essential to understand how these factors interact. Misalignment of parts can lead to premature wear, even with high-quality materials. Regular maintenance can sometimes be overlooked but is key to maximizing wear part longevity.

It’s easy to focus solely on cost when selecting materials. However, considering abrasion resistance is vital. Without it, the overall effectiveness of the crusher can suffer. Evaluating wear parts in real-world conditions can provide insights into what works best. Different applications may require different approaches to abrasion resistance. Understanding these nuances is necessary for making informed decisions.

| Part Name | Material | Hardness (HV) | Abrasion Resistance | Expected Lifespan (Hours) |

|---|---|---|---|---|

| Blow Bar | High Chrome Steel | 700 | Excellent | 2000 |

| Impact Plate | Alloy Steel | 550 | Good | 1500 |

| Side Liners | Manganese Steel | 600 | Very Good | 1800 |

| Rotor | Casting Alloy | 650 | Excellent | 2500 |

| Hammer | Chrome Molybdemum | 720 | Superb | 2200 |

In 2026, the market for impact crusher wear components is evolving. Innovations in materials are a key trend. We see the rise of wear-resistant alloys. These materials increase durability significantly. They help crushers last longer in tough conditions.

Another notable trend is smarter design. Engineers are focusing on optimizing shapes and sizes. This makes components more efficient in reducing wear. New technologies allow for comprehensive testing before production. It’s essential to evaluate how these components perform in real-world conditions.

Yet, there remain challenges in the industry. Not all innovations meet the expected performance. Some wear parts still fail under extreme stress. This gap highlights the need for continual research. Mining and construction sectors must remain vigilant. They should seek feedback and iterate on designs. By addressing these imperfections, the industry can drive forward more resilient solutions.

The quality of wear parts directly impacts the performance of impact crushers. Poor-quality wear parts can lead to frequent breakdowns and costly downtime. When wear parts fail, the entire operation feels the strain. This can affect productivity and profitability.

Choosing wear parts made from superior materials enhances durability. Effective wear parts resonate through consistent operation and reduced operational costs. Yet, some operators overlook the importance of these components. They might prioritize initial cost over quality. This decision can be detrimental in the long run.

Maintenance plays a crucial role in maximizing the life of wear parts. Regular inspections can prevent unexpected failures. However, many tend to neglect this practice, leading to costly repairs. It’s essential to foster a proactive approach towards wear parts management. Ignoring their condition is not an option if longevity is the goal.