-

Home

-

About Us

-

Products

-

News

-

Blog

-

Contact Us

Leave Your Message

The Cone Crusher Bowl is a crucial component in the operation of cone crushers, playing an essential role in the efficiency and effectiveness of aggregate production. With projections from industry reports suggesting that the global cone crusher market is expected to reach $2.3 billion by 2025, understanding the different types and features of cone crusher bowls has never been more critical. According to Dr. James H. Parker, a leading expert in mining and mineral processing, "The selection of the right Cone Crusher Bowl can significantly impact both performance and longevity of the equipment."

As the demands for higher production rates and improved product quality continue to rise, manufacturers and operators must turn their attention to best practices surrounding the Cone Crusher Bowl. The utilization of advanced materials and designs can lead to enhanced wear-resistance and an overall increase in operational uptime. Industry statistics indicate that optimized cone crusher configurations can reduce operational costs by up to 30%, emphasizing the need for informed decision-making when selecting bowl types.

In this overview, we will explore the top Cone Crusher Bowl types available in 2025, delving into their features and the recommendations that can help achieve optimal performance. By understanding these aspects, stakeholders can make informed choices that align with the evolving landscape of the aggregate and mining industries.

The cone crusher bowl is a crucial component in the operation of a cone crusher, as it plays a significant role in the crushing process. It supports the mantle, which is pivotal in breaking down various materials, making it essential for achieving the desired particle size and shape. The design and configuration of cone crusher bowls can vary, impacting their effectiveness in handling different types of materials and operational conditions.

Different types of cone crusher bowls, such as the standard, short head, and deep bowls, offer specific advantages depending on the application. Standard bowls are typically used for primary crushing, providing a larger volume for material processing. In contrast, short head bowls are designed for secondary or tertiary applications, optimizing the final product's granulation. Selecting the right bowl type not only enhances operational efficiency but also prolongs the lifespan of the crusher, reducing maintenance costs and downtime. Understanding these variations and their significance allows operators to make informed decisions that directly impact productivity and longevity of their equipment.

| Bowl Type | Features | Best Practices | Importance |

|---|---|---|---|

| Standard Bowl | Suitable for a wide range of materials | Regular maintenance and checks | Versatility for most applications |

| Short Head Bowl | Enhanced fine material production | Optimize settings for finer outputs | Ideal for specific size reduction tasks |

| Medium Bowl | Balanced for mid-range size reduction | Monitor wear parts closely | Good for varying material sizes |

| Heavy-duty Bowl | Designed for high throughput with tough materials | Conduct extensive wear assessments | Crucial for processing abrasive materials |

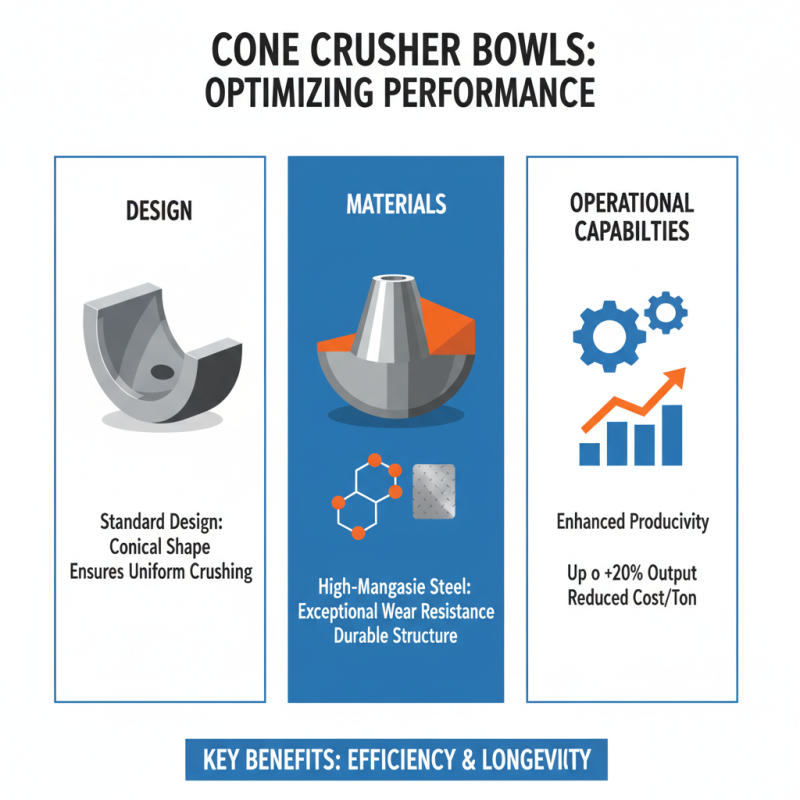

When considering cone crusher bowls, understanding their distinct features is essential for optimizing performance and longevity. Cone crusher bowls can be categorized primarily based on their design, materials, and operational capabilities. Standard bowls, for example, are usually made from high-manganese steel, providing excellent wear resistance while maintaining a reliable structural integrity during the crushing process. Reports suggest that appropriately designed bowls can enhance productivity by as much as 20%, leading to a significant reduction in cost-per-ton.

Another notable type is the hybrid design bowl, which combines multiple materials to optimize durability and reduce wear rates. This innovative approach not only extends the lifespan of the component but also enhances its crushing efficiency. A study by industry analysts indicates that premium hybrid bowls can decrease replacement frequency by approximately 30%, which translates into significant operational savings and higher uptime. Additionally, these bowls can be tailored to specific applications, allowing for improved material handling and adaptability to various crushing requirements.

Furthermore, bowl profiles—such as flat, stepped, or deep configurations—play a crucial role in the end product's specifications. Each profile type offers unique advantages in terms of flow and particle size distribution, contributing to the overall effectiveness of the crushing operation. As the demand for customizable and efficient crushing equipment increases, understanding and utilizing the key features of different cone crusher bowls is vital for industry professionals looking to enhance their operations and achieve optimal results.

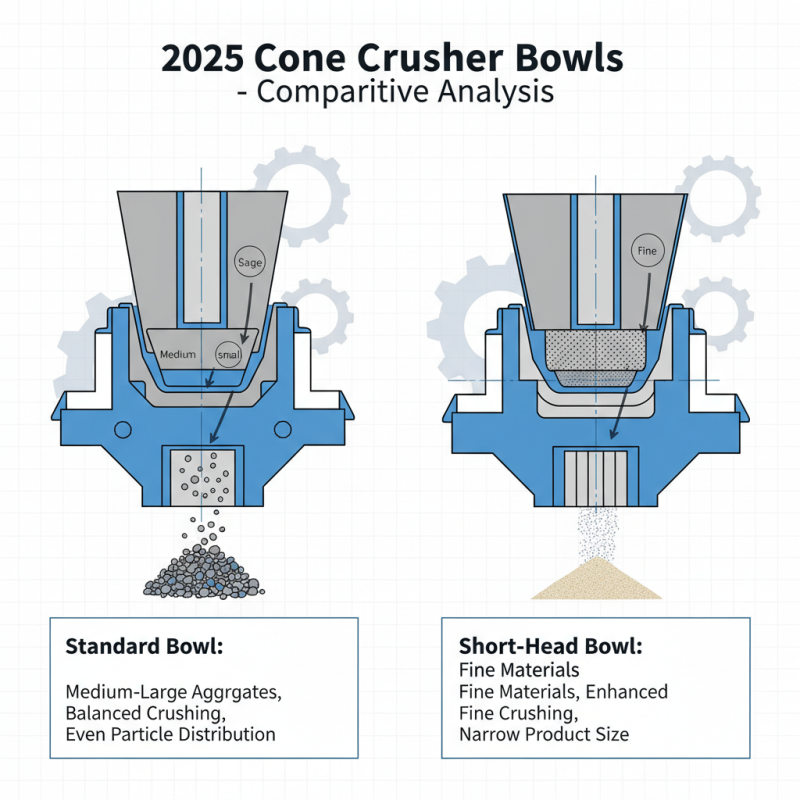

When examining the different types of cone crusher bowls available in the market for 2025, a comparative analysis reveals key distinctions that can significantly influence performance and operational efficiency. The two main categories to consider are the standard bowls and the short-head bowls. Standard bowls are ideal for producing medium to large-sized aggregates, offering a balanced approach to crushing with an even distribution of particle sizes. On the other hand, short-head bowls are designed for finer materials, allowing for a narrower product size distribution and enhanced fine crushing capabilities.

Tips: When selecting a cone crusher bowl type, it is essential to consider the specific material requirements and desired output size. Regular maintenance and adjustment of bowl settings can lead to optimal performance and extended equipment lifespan, ensuring you maximize productivity.

In addition to the type of bowl, the material composition also plays a vital role in the effectiveness of the cone crusher. High manganese steel bowls are popular due to their resilience and ability to withstand heavy wear, while ceramic-coated options are gaining traction for their enhanced durability. Understanding these variances helps operators make informed decisions that align with their specific crushing needs.

Tips: Always conduct thorough inspections and monitor wear rates to determine the best time for bowl replacements. Keeping a log of operational performance can also highlight areas for improvement and adjustment in your crushing process.

Maintaining cone crusher bowls is vital for optimal performance and durability in any crushing operation. Regular inspection is one of the best practices, where operators should routinely check for wear and tear, particularly focusing on the bowl lining. Identifying signs of abrasion or damage early can prevent more extensive repairs and prolong the life of the equipment. Furthermore, ensuring the bowl's tightness during operation can help maintain efficiency and prevent material leakage, which can compromise the crushing process.

Another crucial aspect is lubrication. Adequately lubricating the cone crusher bowl reduces friction and helps to prevent overheating, which can cause severe damage to the machinery. Operators should follow the manufacturer's guidelines regarding lubrication intervals and types. Additionally, keeping the lubrication system clean and free from contaminants is essential to ensure the optimal functionality of the cone crusher.

Finally, operators should be mindful of the feeding material's size and consistency. Overloading the cone crusher can lead to increased stress on the bowl and result in premature wear. By educating the team about the importance of aligned feeding practices and offering training on best operational procedures, facilities can maximize the efficiency and longevity of their cone crusher bowls while minimizing the risk of costly downtime.

As the mining and aggregate industries evolve, the design and technology of cone crusher bowls are expected to follow suit, incorporating innovations that enhance performance and sustainability. Future trends suggest a shift towards materials that not only increase durability but also minimize environmental impact. Advanced alloys and composites could provide increased resistance to wear and corrosion, allowing for longer service life and reduced material waste. Furthermore, the integration of smart technologies, such as sensors and IoT capabilities, promises to optimize the operation and maintenance of cone crushers, enabling predictive maintenance and reducing downtime.

In addition to improved material science and smart technology, design enhancements are likely to focus on efficiency and adaptability. Bowl designs may become more modular, allowing for easier optimization depending on specific mineral properties or production requirements. Enhanced computational fluid dynamics modeling will aid in creating shapes that maximize crushing efficiency while minimizing energy consumption. This adaptability will enable operators to tailor their equipment to the ever-changing demands of the market, ultimately leading to better productivity and a stronger emphasis on sustainable practices in mining and construction.